Metallocene, catalyst composition and application of metallocene in synthetic base oil

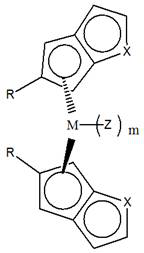

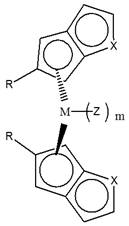

A catalyst and metallocene technology, which is applied in the field of metallocene catalyst composition catalyzing heavy alpha-olefin oligomerization to prepare synthetic base oil, can solve the problems of low selectivity, low economical efficiency of PAO synthetic oil, etc., to optimize catalytic performance, improve Dispersion effects, achieving chain initiation and chain growth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

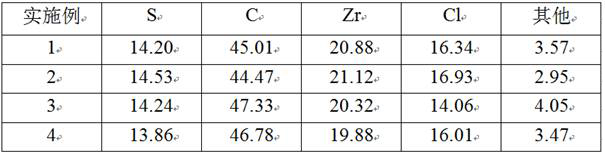

Embodiment 1

[0055] (1) Add 92g propionyl chloride (92.5g / mol) and 84g thiophene (84.14g / mol) to 672g benzene (0.8765g / cm3), stir well, cool to -20°C, and then dropwise add 13g anhydrous chlorine tin (260g / mol). The reaction was stirred for 20h. The product Pa1 (140.14 g / mol) was isolated by extraction-vacuum distillation technique, and the yield was 90%.

[0056] (2) 70g of the Pa1 product (140.14g / mol) obtained in step (1) and 91g of hexamethylenetetramine (140g / mol) were added to 92g of acetic anhydride (102g / mol), and the reaction was stirred for 20h. is 90°C. 56ml of sodium hydroxide with a concentration of 2mol / L was added, and the reaction was stirred for 3h. Extraction technology separates organic matter. Then, the extract and 14.4 g of methanesulfonic acid (96 g / mol) were added to 560 g of dichloromethane, and the reaction was stirred at a temperature of 30 °C and a reaction time of 2 h. The product Pb1 was isolated by extraction-vacuum distillation technique, and the yield w...

Embodiment 2

[0066] (1) Add 92g propionyl chloride (92.5g / mol) and 100g thiophene (84.14g / mol) to 1000g benzene (0.8765g / cm3), stir well, cool to -20°C, and then dropwise add 2.6g anhydrous Tin chloride (260g / mol). The reaction was stirred for 20h. The product Pa2 (151g / mol) was obtained by extraction-vacuum distillation technique. The yield was 81%.

[0067] (2) 70g of the Pa2 product (140.14 g / mol) obtained in step (1) and 112g of hexamethylenetetramine (140g / mol) were added to 102g of acetic anhydride (102g / mol), and the reaction was stirred for 20h. is 90°C. 25ml of sodium hydroxide with a concentration of 4mol / L was added, and the reaction was stirred for 3h. Extraction technology separates organic matter. Then, the extract and 24 g of methanesulfonic acid (96 g / mol) were added to 700 g of dichloromethane, and the reaction was stirred at a temperature of 30 °C and a reaction time of 2 h. The product Pb2 was obtained by extraction-vacuum distillation technique. The yield was 91%...

Embodiment 3

[0077] (1) Add 106g butyryl chloride (106.5g / mol) and 84g thiophene (84.14g / mol) to 672g benzene (0.8765g / cm3), stir well, cool to -20°C, and then dropwise add 13g anhydrous chlorine tin (260g / mol). The reaction was stirred for 20h. The product Pa3 (151g / mol) was obtained by extraction-vacuum distillation technique. The yield was 90%.

[0078] (2) 77g of the Pa3 product (154.14g / mol) obtained in step 1 and 91g of hexamethylenetetramine (140g / mol) were added to 92g of acetic anhydride (102g / mol), and the reaction was stirred for 20h at a reaction temperature of 90 °C. 56ml of sodium hydroxide with a concentration of 2mol / L was added, and the reaction was stirred for 3h. Extraction technology separates organic matter. Then, the extract and 14.4 g of methanesulfonic acid (96 g / mol) were added to 616 g of dichloromethane, and the reaction was stirred at a temperature of 40 °C and a reaction time of 2 h. The product Pb3 was obtained by extraction-vacuum distillation technique...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com