Exhaust utilization device of solid fuel cell

A solid fuel cell and fuel technology, applied in solid electrolyte fuel cells, fuel cells, electrical components, etc., can solve problems such as adverse environmental effects, avoid sensible heat loss, reduce the thickness of the liquid film layer, and reduce the concentration of CO2 at the outlet. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

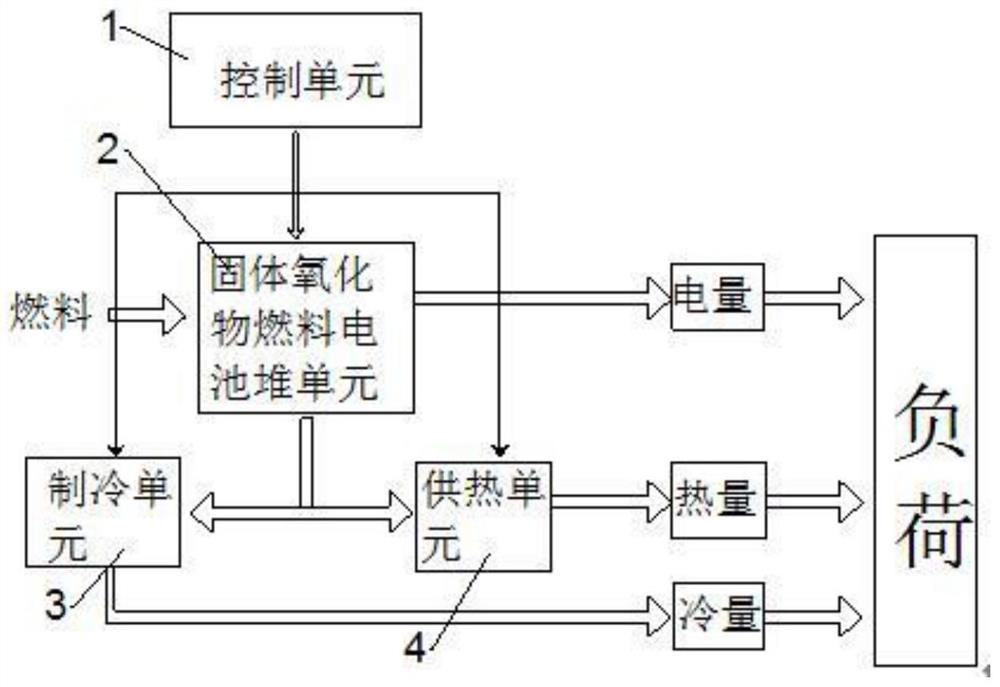

[0034] combine figure 2 , an exhaust gas utilization device of a solid fuel cell, including a battery stack unit 2 for providing electrical energy, including a control unit 1 for controlling the battery stack unit 2, and the exhaust gas of the battery stack unit 2 is the refrigeration unit 3 and the power supply unit. The heating unit 4 provides energy, the control unit 1 controls the switching of the working mode between the heating unit 4 and the cooling unit 3, the battery stack unit 2 is mainly used for power generation, and the control unit 1 predicts the demand and feedback according to the power of the load. The real-time data is compared to adjust the power output of the battery stack unit 2 to meet the needs of the load. The battery stack unit 2 will generate a lot of energy while generating electricity, and this energy will be used for the cooling unit 3 and the heating unit 4 to provide users with The heat and cooling required for daily life have achieved the effec...

Embodiment 2

[0037] Since the outlet of the anode of the stack unit will be discharged by H 2 , CO, H 2 O, CO 2 and CH 4 In order to carry out low-carbon emission treatment of the exhaust gas, the exhaust gas discharged from the anode is transported to the capture unit to achieve the purpose of emission reduction and environmental protection.

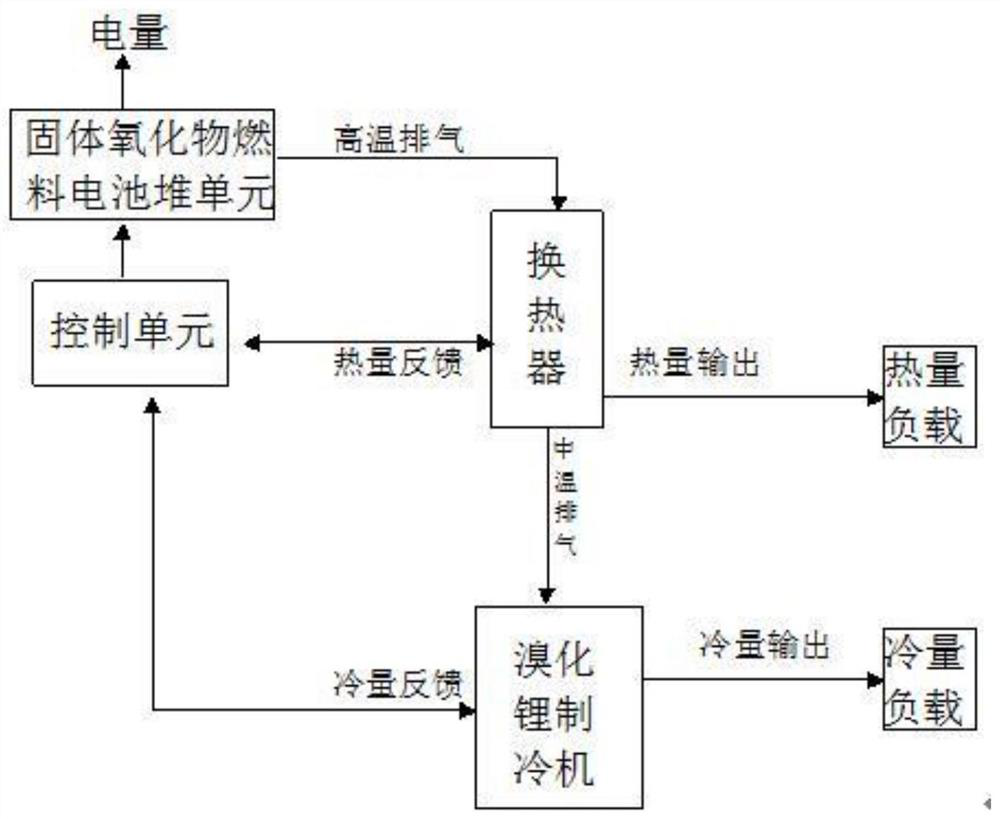

[0038] combine Figure 4 , the capture unit comprises that the tail gas of the anode and cathode of the battery stack unit 2 enters the waste heat boiler steam turbine one 5 after catalytic combustion, the waste heat boiler steam turbine one 5 is used for power generation, and the waste heat boiler steam The exhaust gas of turbine one 5 enters CO 2 High temperature separation membrane 7, the CO 2 Separated from the exhaust gas, the anode of the battery stack unit 2 adopts pure O 2 As the oxidant of the anode fuel, the anode of the cell stack unit 2 undergoes an electrochemical reaction of CO to generate high-temperature CO. 2 The exhaust gas ...

Embodiment 3

[0042] the CO 2 The high temperature separation membrane 7 adopts a hollow fiber membrane contactor, and the CO 2 High temperature separation membrane 7 uses amino acid salt as CO 2 Collecting agent, inorganic salt potassium borate and piperazine are added to the amino acid salt solution as activators to form a composite absorbent, and the composite absorbent will affect the absorption of CO by the amino acid salt 2 process that accelerates CO 2 mass transfer efficiency.

[0043] the CO 2 The mass transfer coefficient K of the high temperature separation membrane satisfies: K=Gln(C in / C out ) / AL, where G is the gas flow rate (m 3 / s), A is the cross-sectional area of the membrane structure (m 2 ), L is the effective length of the membrane structure (m), C in and C out are the CO in the gas phase inlet and outlet of the separation membrane structure, respectively 2 concentration (mol / L).

[0044] the CO 2 The mass transfer flux W of the high temperature separatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com