Oil-control and hair loss-prevention composition, oil-control and hair loss-prevention product and preparation method of oil-control and hair loss-prevention product

An anti-hair loss and composition technology, applied in the direction of drug combination, cosmetic preparations, cosmetics, etc., can solve the problems of poor safety and low cure rate, and achieve the effect of reducing concentration, eliminating cell inflammation, and inhibiting the activity of 5α-reductase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

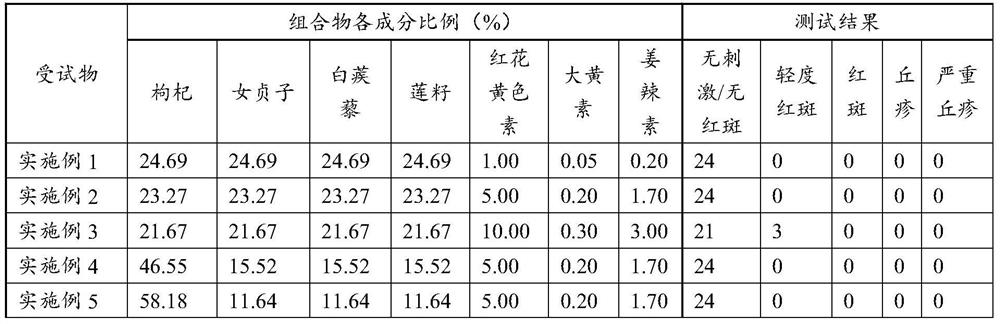

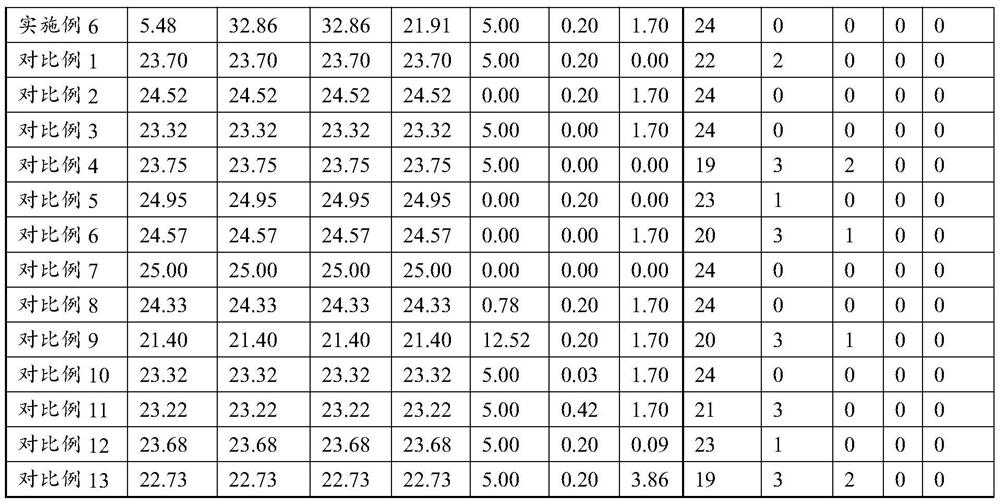

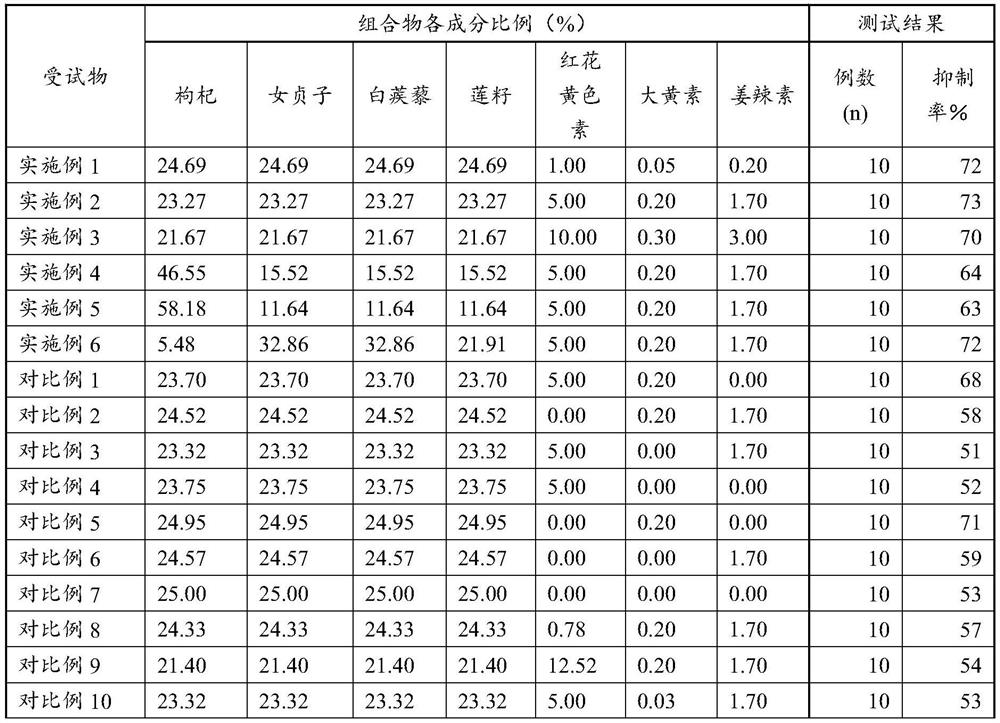

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of an oil-controlling anti-hair loss product, comprising the following steps:

[0041] Grind Ligustrum lucidum, Tribulus terrestris, and lotus seeds into powder with a particle size of 100 μm to 200 μm, then mix Lycium barbarum and the powder, wet the powder raw material with water at 36 ° C to 45 ° C, add lactic acid bacteria seed solution and stir evenly , compacted, and fully fermented in a closed and anaerobic environment, such as after 65h to 75h, extracted with ethanol aqueous solution, and filtered to remove the original medicinal powder to obtain oil control and anti-hair loss products;

[0042] Further, after the safflower is fully soaked in a sufficient amount of pure water, for example, after 65h to 75h, the safflower yellow pigment is extracted, and the soaking solution is concentrated and dried to obtain a high content of safflower yellow pigment; Fine powder, add ethanol to extract at least 2 times, ...

Embodiment 1

[0049] The present embodiment carries out the preparation of oil-controlling anti-hair loss liquid, comprising the following steps:

[0050] Step 1. Grind 100g of Ligustrum lucidum, 100g of Tribulus terrestris and 100g of lotus seeds into powder with a particle size of 100μm to 200μm, then mix the powder with 100g of wolfberry, wet the powder raw material with water at 40°C, and add 20g of lactic acid bacteria seeds The liquid was stirred evenly and compacted. After 72h of insulation and fermentation in a closed, anaerobic environment, 2000g of 68% ethanol aqueous solution was used for extraction, and after filtering to remove the medicinal residues (i.e. privet seed powder, tribulus terrestris powder, lotus seed powder, wolfberry) The obtained extract was an ethanolic solution.

[0051] Step 2. Put 18.84g of safflower into a sufficient amount of pure water to soak for 72 hours and then extract the yellow anthocyanin. The soaking solution is concentrated and dried to obtain 4....

Embodiment 2

[0055] The present embodiment carries out the preparation of oil-controlling anti-hair loss liquid, comprising the following steps:

[0056] Step 1. Grind 100g of Ligustrum lucidum, 100g of Tribulus terrestris and 100g of lotus seeds into powder with a particle size of 100μm to 200μm, then mix the powder with 100g of wolfberry, wet the powder raw material with water at 40°C, and add 20g of lactic acid bacteria seeds The liquid was stirred evenly and compacted. After 72h of insulation and fermentation in a closed, anaerobic environment, 6000g of 68% ethanol aqueous solution was used for extraction, and after filtering and removing the medicinal residues (i.e. privet seed powder, tribulus terrestris powder, lotus seed powder, wolfberry) The obtained extract was an ethanolic solution.

[0057] Step 2. Put 100g of safflower into enough pure water to soak for 72 hours, and then extract the yellow anthocyanin. The soaking solution is concentrated and dried to obtain 21.5g of high-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com