Method for degrading VOCs (Volatile Organic Compounds) by catalyzing ozone oxidation through alpha-crystal-form manganese dioxide

A technology of manganese dioxide and ozone oxidation, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve the problem of low catalytic degradation rate and achieve no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

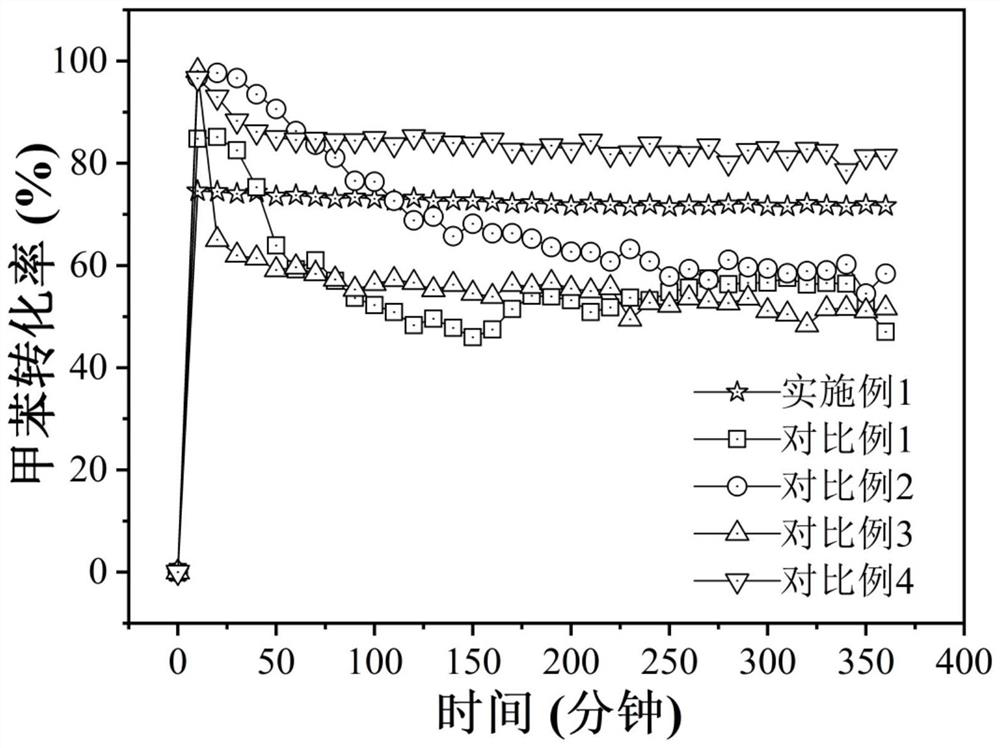

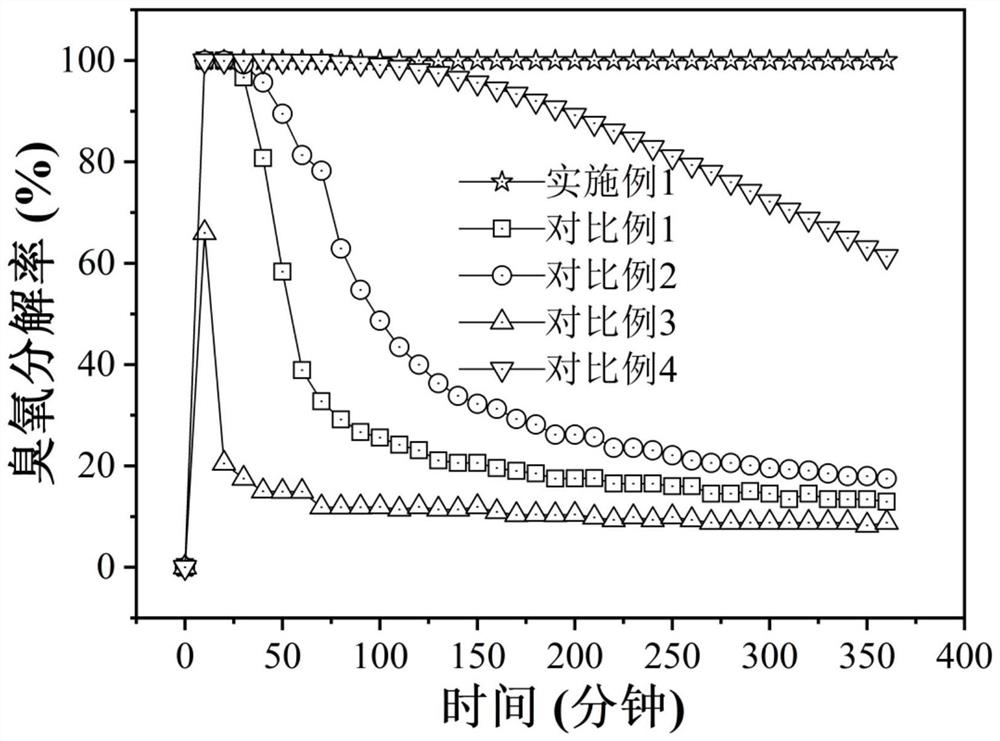

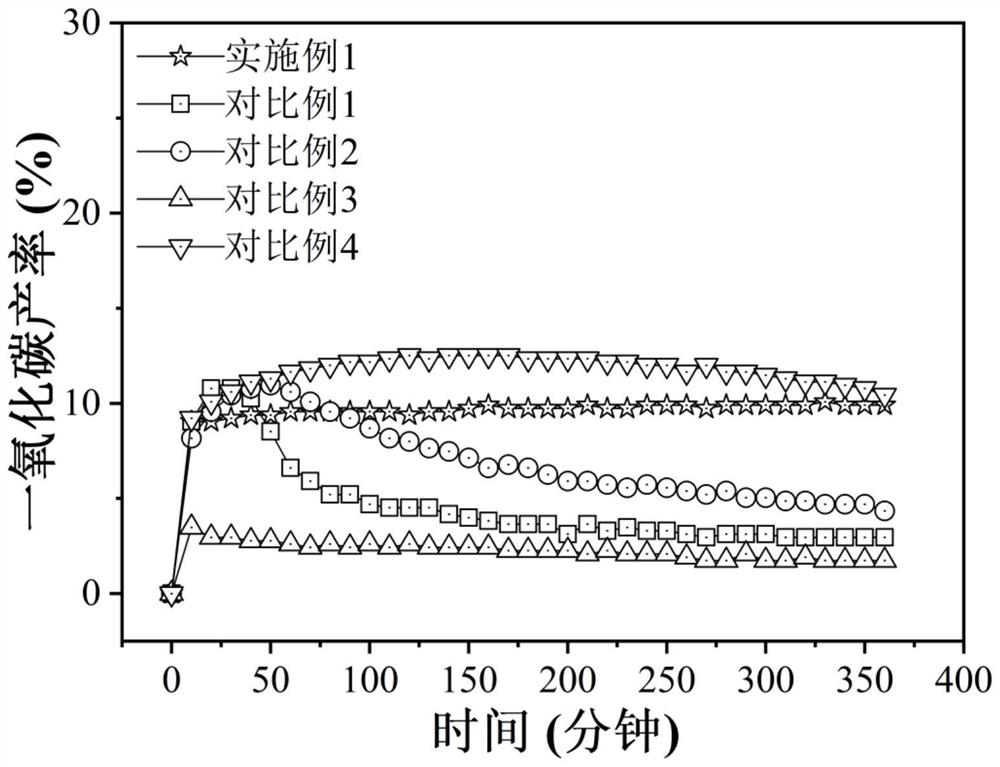

[0048] The present embodiment provides a method for catalyzing ozone oxidation and degrading VOCs by manganese dioxide in α crystal form, and the method includes:

[0049] The VOCs mixed gas and ozone pass through a fixed bed reactor equipped with α-crystalline manganese dioxide, and the catalytic ozone oxidation reaction at a temperature of 30 ° C is carried out to degrade VOCs; the volume ratio of toluene and ozone in the VOCs mixed gas is 1:12 Nitrogen is introduced into the VOCs mixed gas as a balance gas, and the flow rate of the VOCs mixed gas is controlled to be 200 mL / min; the usage amount of the catalyst in the catalytic ozone oxidation reaction is 0.1 g, and the reaction of the VOCs mixed gas is 0.1 g. The airspeed is 120L / h / g;

[0050] The preparation method of the manganese dioxide of the α crystal form comprises the following steps:

[0051] The molar ratio of manganese sulfate tetrahydrate and potassium permanganate is 1:5.84, dissolved in deionized water, and s...

Embodiment 2

[0053] The present embodiment provides a method for catalyzing ozone oxidation and degrading VOCs by manganese dioxide in α crystal form, and the method includes:

[0054] The VOCs mixed gas and ozone pass through a fixed bed reactor equipped with α-crystal manganese dioxide, and the catalytic ozone oxidation reaction at a temperature of 30 ° C is carried out to degrade VOCs; the volume ratio of toluene and ozone in the VOCs mixed gas is 1:16 Nitrogen is introduced into the VOCs mixed gas as a balance gas, and the flow rate of the VOCs mixed gas is controlled to be 200 mL / min; the usage amount of the catalyst in the catalytic ozone oxidation reaction is 0.1 g, and the reaction of the VOCs mixed gas is 0.1 g. The airspeed is 120L / h / g;

[0055] The preparation method of the manganese dioxide of the α crystal form comprises the following steps:

[0056] The molar ratio of manganese chloride and potassium permanganate was 1:5.84. After mixing, the hydrothermal reaction was carrie...

Embodiment 3

[0058] The present embodiment provides a method for catalyzing ozone oxidation and degrading VOCs by manganese dioxide in α crystal form, and the method includes:

[0059] The VOCs mixed gas and ozone pass through a fixed bed reactor equipped with α-crystal manganese dioxide, and the catalytic ozone oxidation reaction at a temperature of 40 ° C is carried out to degrade VOCs; the volume ratio of toluene and ozone in the VOCs mixed gas is 1:12 Nitrogen is introduced into the VOCs mixed gas as a balance gas, and the flow rate of the VOCs mixed gas is controlled to be 100 mL / min; the usage amount of the catalyst in the catalytic ozone oxidation reaction is 0.05 g, and the reaction of the VOCs mixed gas is 0.05 g. The airspeed is 240L / h / g;

[0060] The preparation method of the manganese dioxide of the α crystal form comprises the following steps:

[0061] Manganese nitrate, potassium permanganate and deionized water were mixed in a molar ratio of 1:5.84, and then subjected to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com