Environment-friendly low-surface-energy antifouling paint used under waterline

A low surface energy, antifouling coating technology, applied in antifouling/underwater coatings, epoxy resin coatings, wax coatings, etc. The effect of strong fouling, reducing toxicity and low surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

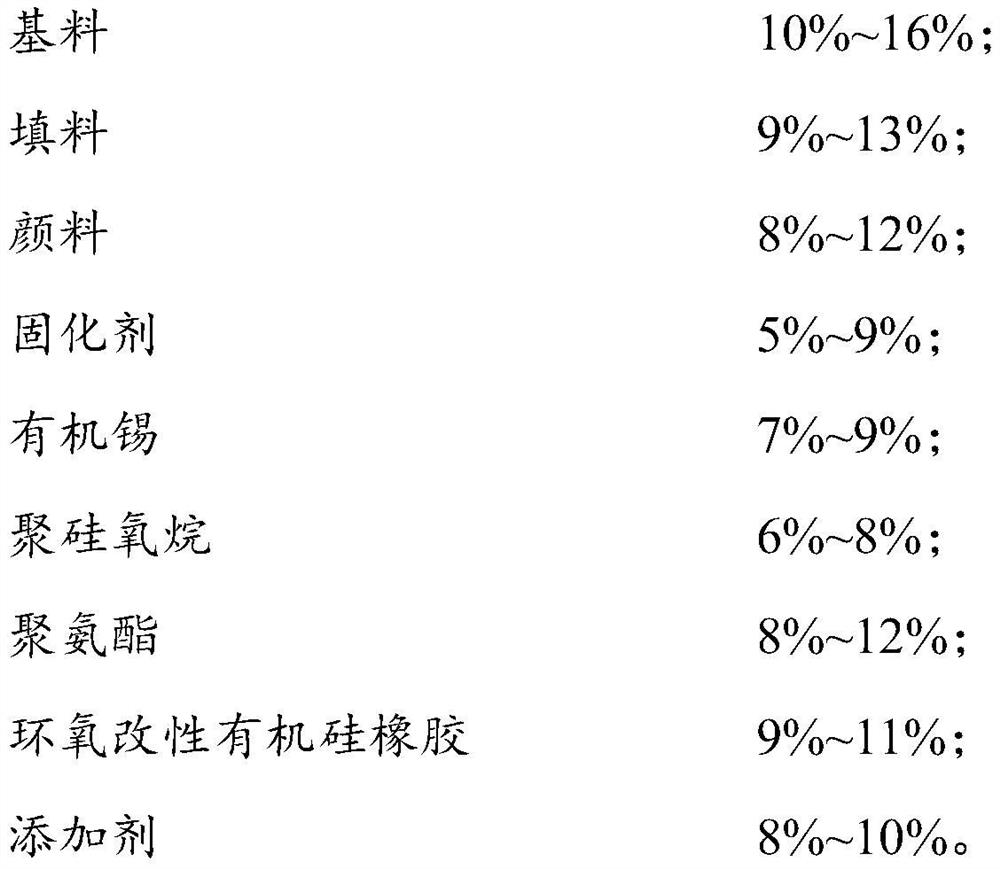

[0022] An environment-friendly low-surface-energy antifouling paint for use under the waterline, which is prepared from the following mass percentages of raw materials:

[0023]

[0024]

[0025] In this embodiment, the base material is a mixture of polydimethylsiloxane and epoxy resin.

[0026] In this embodiment, the filler is a mixture of polytetrafluoroethylene and paraffin oil.

[0027] In this embodiment, the pigment is a mixture of titanium dioxide and magnesium oxide.

[0028] In this embodiment, the curing agent is polyamide.

[0029] In this embodiment, the additive is a mixture of polytetrafluoroethylene, graphite intercalation compound and fluorinated carbonate.

Embodiment 2

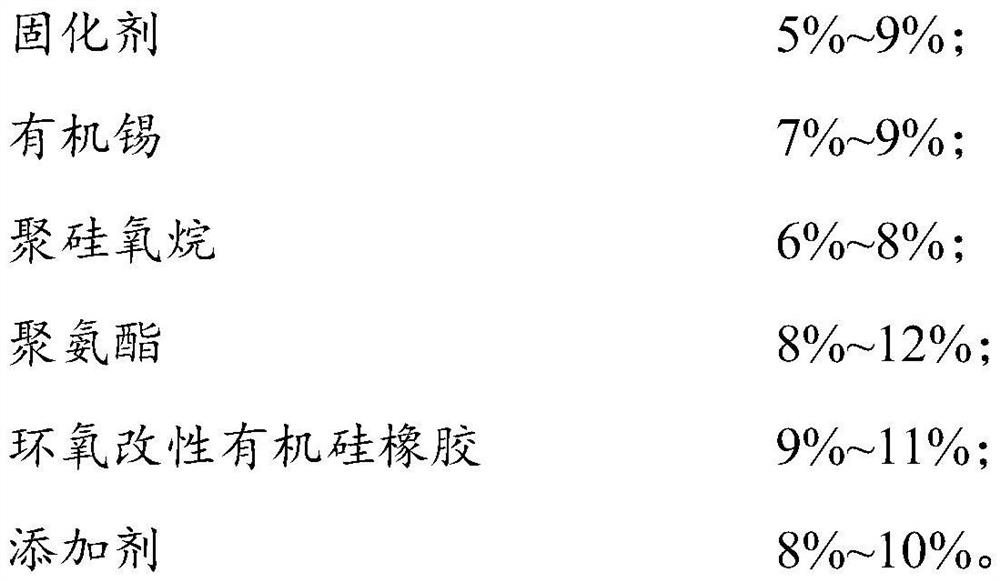

[0031] An environment-friendly low-surface-energy antifouling paint for use under the waterline, which is prepared from the following mass percentages of raw materials:

[0032]

[0033] In this embodiment, the base material is a mixture of polydimethylsiloxane and epoxy resin.

[0034] In this embodiment, the filler is a mixture of polytetrafluoroethylene and paraffin oil.

[0035] In this embodiment, the pigment is a mixture of titanium dioxide and magnesium oxide.

[0036] In this embodiment, the curing agent is polyamide.

[0037] In this embodiment, the additive is a mixture of polytetrafluoroethylene, graphite intercalation compound and fluorinated carbonate.

Embodiment 3

[0039] An environment-friendly low-surface-energy antifouling paint for use under the waterline, which is prepared from the following mass percentages of raw materials:

[0040]

[0041] In this embodiment, the base material is a mixture of polydimethylsiloxane and epoxy resin.

[0042] In this embodiment, the filler is a mixture of polytetrafluoroethylene and paraffin oil.

[0043] In this embodiment, the pigment is a mixture of titanium dioxide and magnesium oxide.

[0044] In this embodiment, the curing agent is polyamide.

[0045] In this embodiment, the additive is a mixture of polytetrafluoroethylene, graphite intercalation compound and fluorinated carbonate.

[0046] The preparation method of the environment-friendly low-surface-energy antifouling paint for use under the waterline specifically includes the following steps:

[0047] Step 1: The organotin is pumped into the high-level tank, the polysiloxane is pumped into another high-level tank, and the two are sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com