Preparation method and storage method of concentrated dried milk cake

A technology for condensed milk and tofu, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of decreased texture properties, internal structure damage, mixed natural fermentation bacteria, etc., and achieves white color, smooth surface, and color. glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The embodiment of the present application provides a preparation method of concentrated milk tofu, comprising the following steps:

[0047] S1, after the concentrated milk is heated and sterilized, cool, then add a starter and calcium chloride to obtain the milk to be fermented;

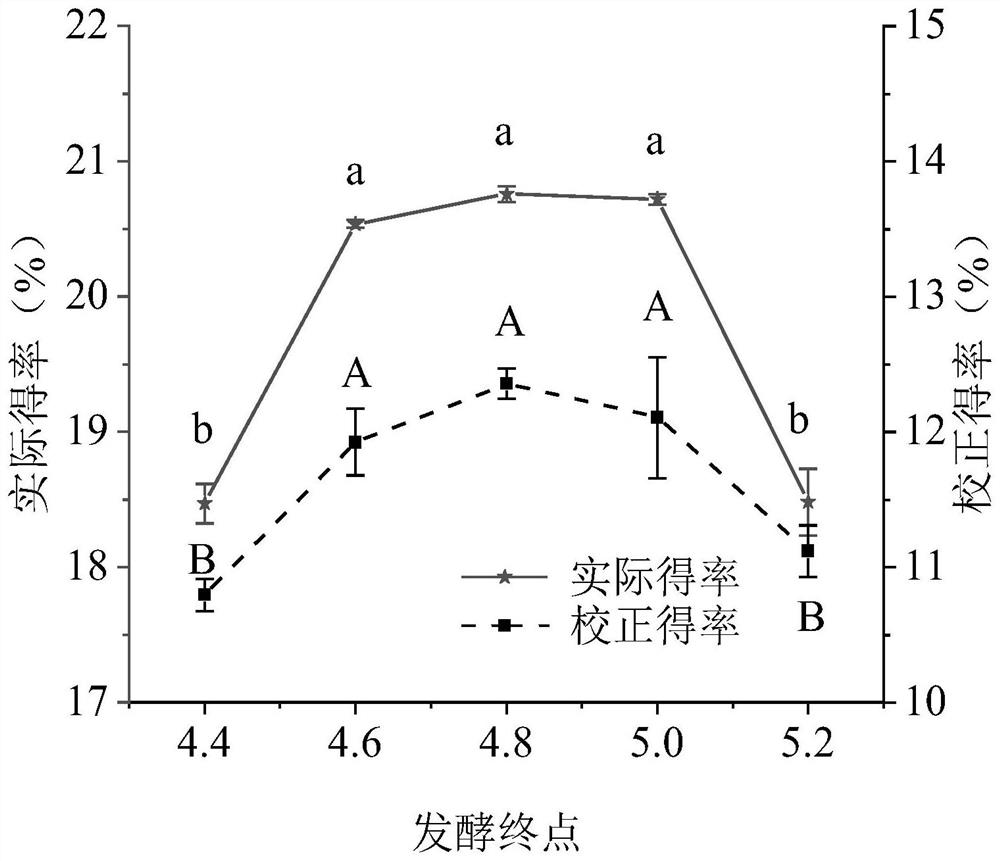

[0048] S2, placing the milk to be fermented in an incubator at a temperature of 20-24° C. to ferment the curd, and monitoring its pH, when the pH reaches 4.4-5.2, stop the fermentation to obtain fermented milk;

[0049] S3, remove the upper layer of milk skin of the fermented milk, and heat the lower layer of fermented milk to curd, then discharge the whey, and then place it in a mold to form, that is, to obtain concentrated milk tofu;

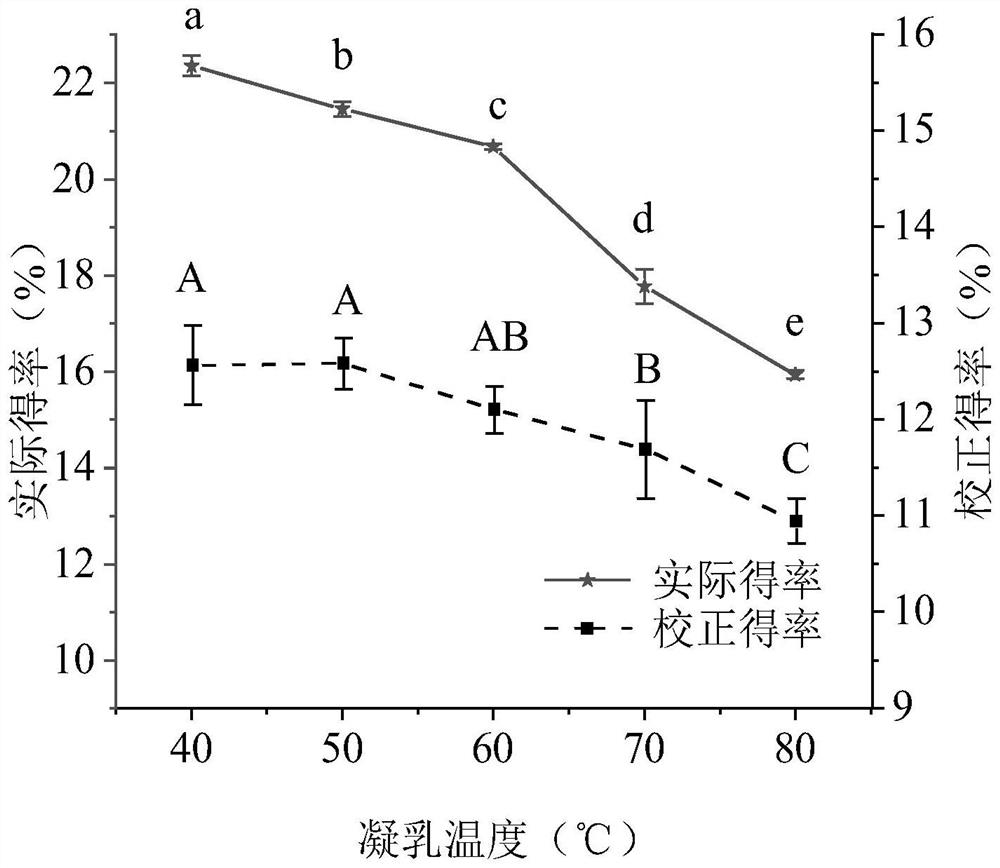

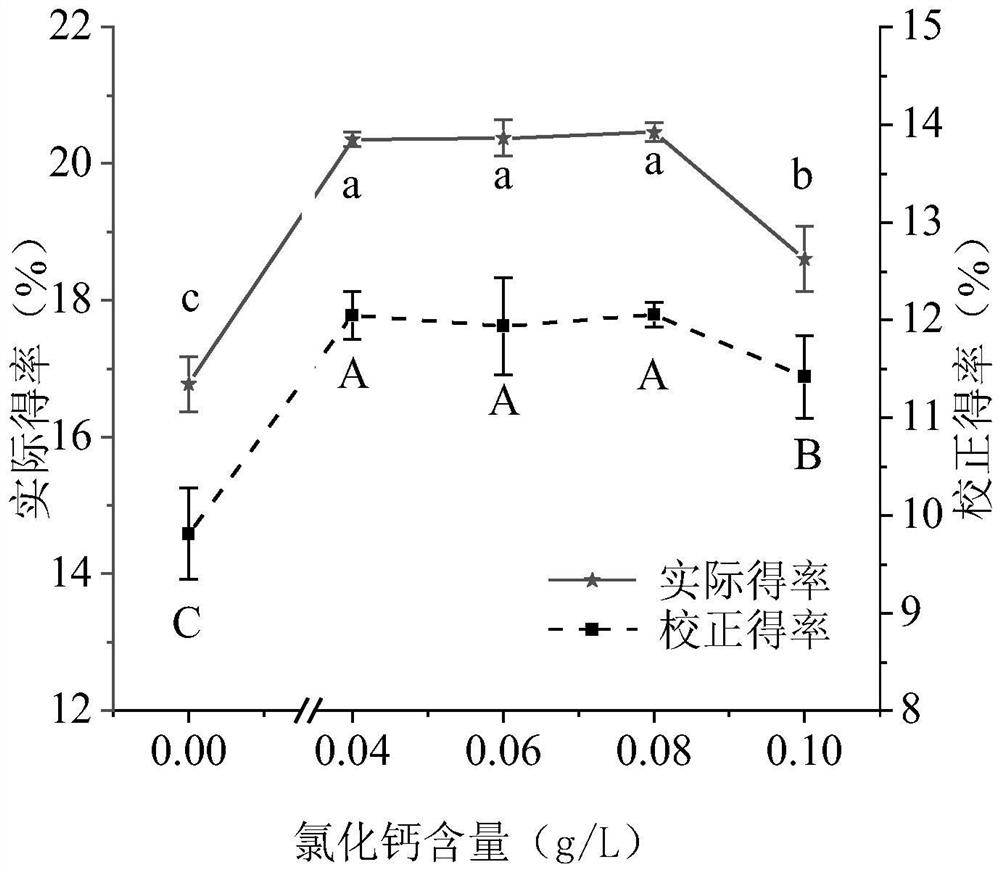

[0050] Wherein, the concentration of calcium chloride in the milk to be fermented is 0.04-0.1 g / L, and the temperature of the heated curd is 40-80°C.

[0051] In the preparation method of the concentrated milk tofu of the present application, the concentrated...

Embodiment 1

[0077] The embodiment of the present application provides a preparation method of concentrated milk tofu, comprising the following steps:

[0078] S1. Heat the concentrated milk water bath to 72°C for sterilization for 15s, then cool to 22°C, and then add starter and calcium chloride to obtain the milk to be fermented;

[0079] S2. Place the milk to be fermented in an incubator at a temperature of 22°C for fermentation, and monitor its pH. When the pH reaches 5.0, stop the fermentation to obtain fermented milk;

[0080] S3, remove the upper layer of milk skin of the fermented milk, and heat the lower layer of fermented milk to curd, then discharge the whey, and then place it in a mold to form, that is, to obtain concentrated milk tofu;

[0081] Among them, the concentration of calcium chloride in the milk to be fermented is 0.06g / L, the concentration of the starter is 0.05g / L, the starter is purchased from Chr. Hansen, the model is CHN-11, and the heating curdling temperature ...

Embodiment 2

[0083] The embodiment of the present application provides a preparation method of concentrated milk tofu, comprising the following steps:

[0084] S1. Heat the concentrated milk water bath to 72°C for sterilization for 15s, then cool to 22°C, and then add starter and calcium chloride to obtain the milk to be fermented;

[0085] S2, place the milk to be fermented in an incubator at a temperature of 22°C for fermentation, and monitor its pH, when the pH reaches 4.4-5.2, stop the fermentation to obtain fermented milk;

[0086] S3, remove the upper layer of milk skin of the fermented milk, and heat the lower layer of fermented milk to curd, then discharge the whey, and then place it in a mold to form, that is, to obtain concentrated milk tofu;

[0087] Wherein, the concentration of calcium chloride in the milk to be fermented is 0.06g / L, the concentration of the starter is 0.05g / L, the starter is purchased from Chr. Hansen, the model is CHN-11, and the heating curdling temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com