Molecular sieve packaged core-shell catalyst and preparation method thereof

A technology of core-shell catalysts and molecular sieves, applied in the direction of molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult molecular dynamics diffusion of reaction molecules and products, destruction of molecular sieve channel structure, poor metal dispersion, etc. Achieve the effect of high utilization rate of active center, high catalytic activity and guaranteed dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

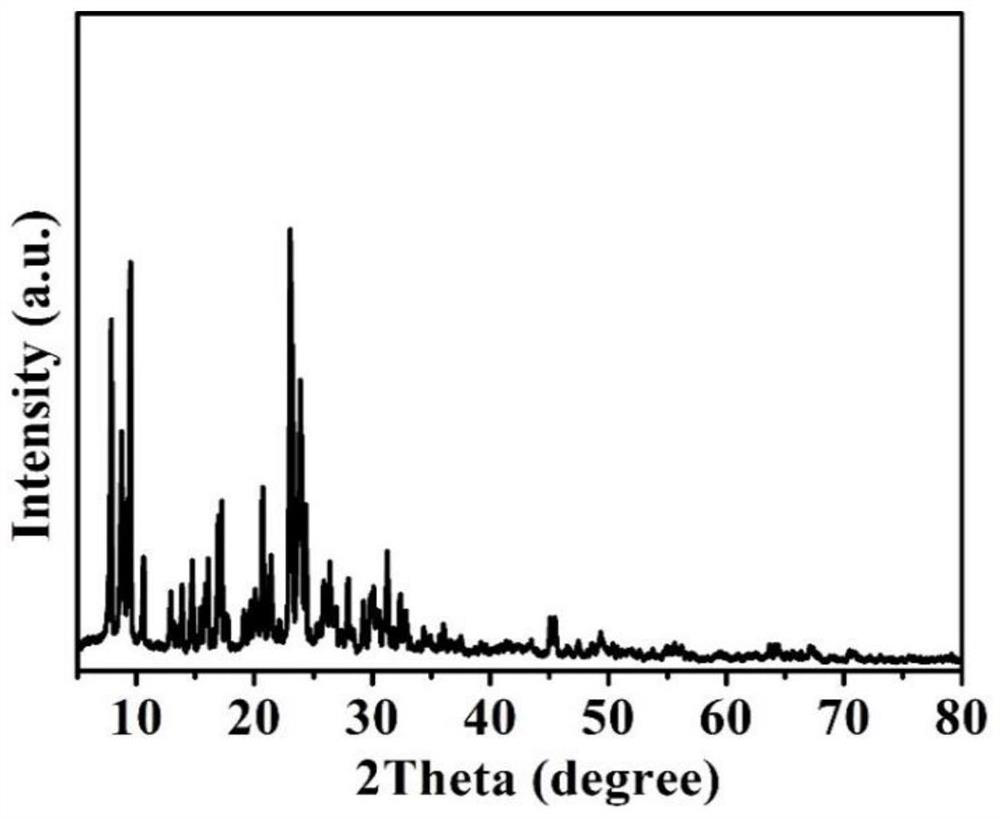

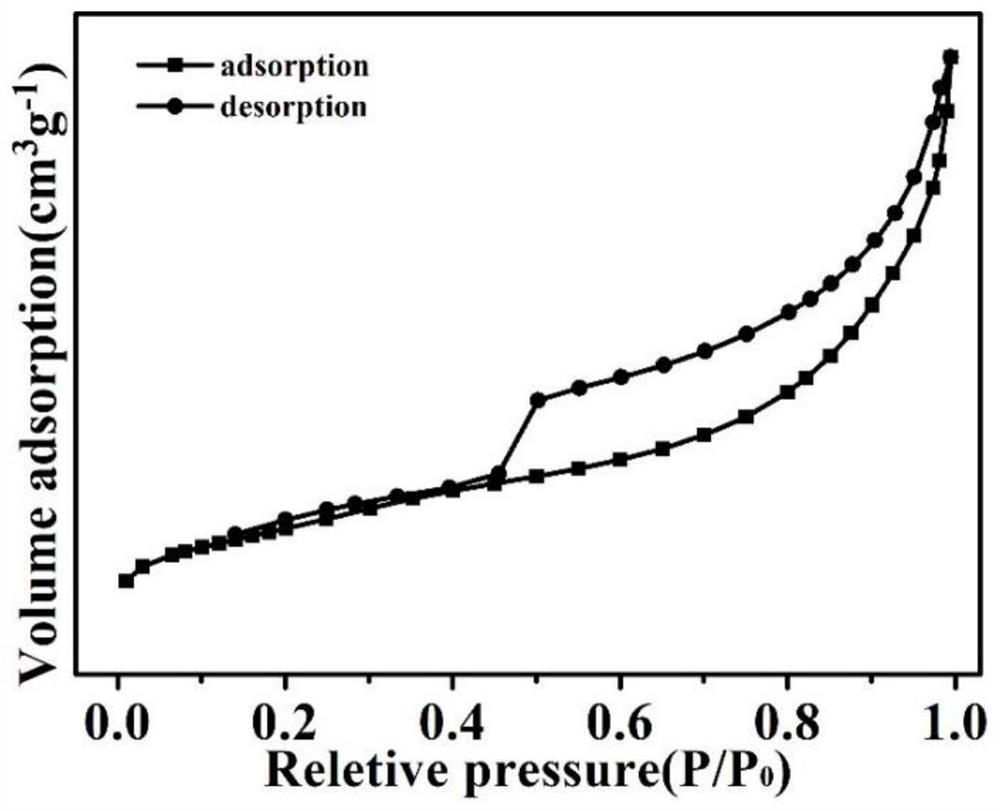

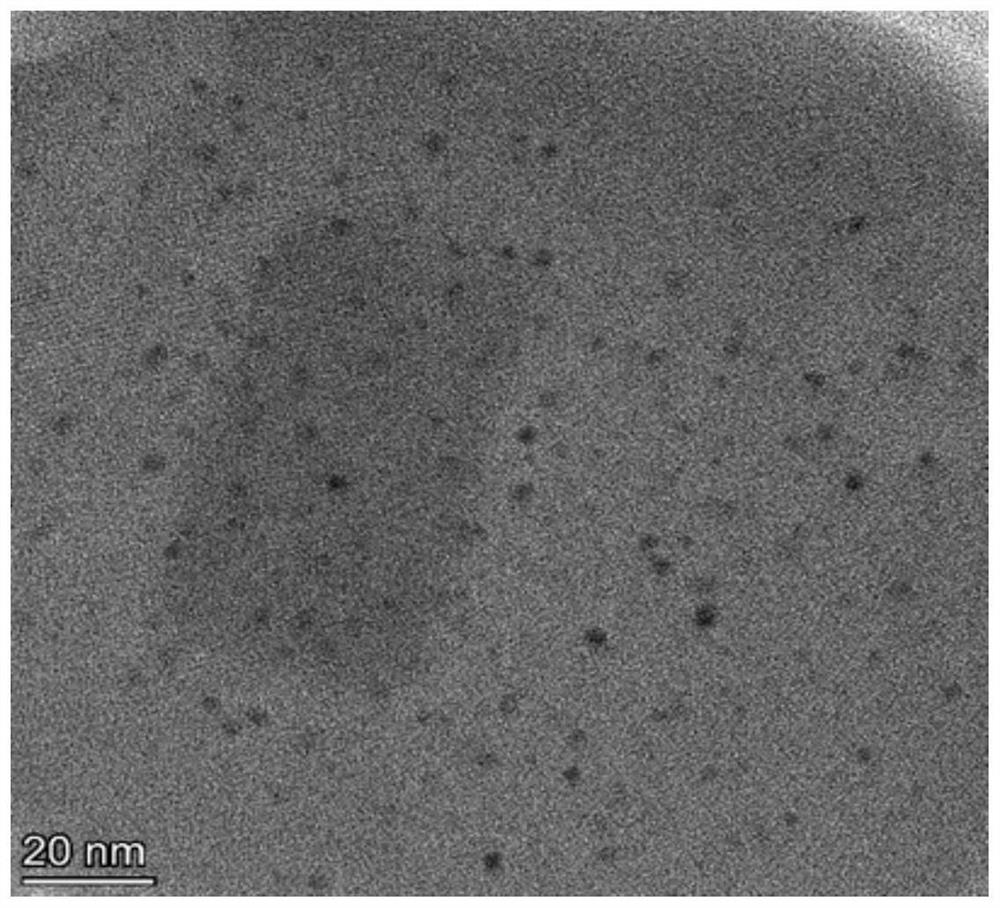

Image

Examples

Embodiment 1

[0032] (1) Preparation of CuPt / SSZ-39: 3.6g Y zeolite, 23.5g 2,6-dimethyl-N,N-dimethylpiperidine, 14.8g silica sol, 4.8g γ-aminopropyltriethyl Oxysilane and 30 g of deionized water were mixed and stirred thoroughly; the above mixed solution was transferred to a high-pressure reaction kettle, and hydrothermally crystallized at 160 °C for 2 d; after the reaction was completed, filter and separate, and the filter cake was washed with deionized water to medium properties, dried at 80°C for 8h, and then calcined in air at 550°C for 6h to obtain modified SSZ-39 molecular sieve. Weigh 0.03g of chloroplatinic acid and 0.2g of copper sulfate, dissolve them in deionized water to make chloroplatinic acid solution and copper sulfate solution, add 2g of modified SSZ-39 molecular sieve for dipping, filter, wash, and dry the filter cake at 60 °C for 6 hours , to obtain CuPt / SSZ-39.

[0033] (2) Preparation of molecular sieve-encapsulated core-shell catalyst: Measure 8 mL of tetrapropylammon...

Embodiment 2

[0036] (1) Preparation of CuPt / SSZ-39: 5g Beta zeolite, 25.8g 2,6-dimethyl-N,N-dimethylpiperidine, 17.5g sodium silicate, 4.8g γ-aminopropyltrimethoxy Silane and 30 g of deionized water were mixed, and stirred thoroughly; the above mixed solution was transferred to a high-pressure reactor, and crystallized at 165 ° C for 2 d; Dry at 60°C for 6h, and then calcinate in air at 550°C for 7h to obtain modified SSZ-39 molecular sieve. Weigh 0.1g of platinum nitrate and 0.3g of copper nitrate, dissolve them in deionized water to make platinum nitrate solution and copper nitrate solution, add 2g of modified SSZ-39 molecular sieve to impregnate, filter, wash, and dry the filter cake at 60 °C for 6h, CuPt / SSZ-39 was obtained.

[0037] (2) Preparation of molecular sieve-encapsulated core-shell catalyst: Measure 8 mL of tetrapropylammonium bromide solution, 6 mL of methyl orthosilicate and 20 mL of deionized water, weigh 2 g of CuPt / SSZ-39, stir well and transfer to the reaction In the ...

Embodiment 3

[0039] (1) Preparation of CuPt / SSZ-39: 5g MOR zeolite, 30.3g N-ethyl-N-propyl-2,6-dimethylpiperidine, 25.7g sodium silicate, 5.2g γ-aminopropyl Mix trimethoxysilane with 50 g of deionized water, and stir thoroughly; transfer the above mixed solution into a high-pressure reaction kettle, and hydrothermally crystallize at 160 °C for 2 d; after the reaction, filter and separate, and wash the filter cake with deionized water until Neutral, dried at 80°C for 7.5h, and then calcined in air at 750°C for 7h to obtain modified SSZ-39 molecular sieve. Weigh 0.15g of ammonium chloroplatinate and 0.4g of copper acetate, dissolve them in deionized water to make ammonium chloroplatinate solution and copper acetate solution, add 2g of modified SSZ-39 molecular sieve for dipping, filter, wash, and filter cake at 80℃ After drying for 7.5 h, CuPt / SSZ-39 was obtained.

[0040] (2) Preparation of molecular sieve-encapsulated core-shell catalyst: weigh 8 mL of hexadecyl trimethyl ammonium bromide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com