Method for regulating and controlling insulating framework of high-dielectric and high-voltage-resistant SrTiO3 dielectric ceramic

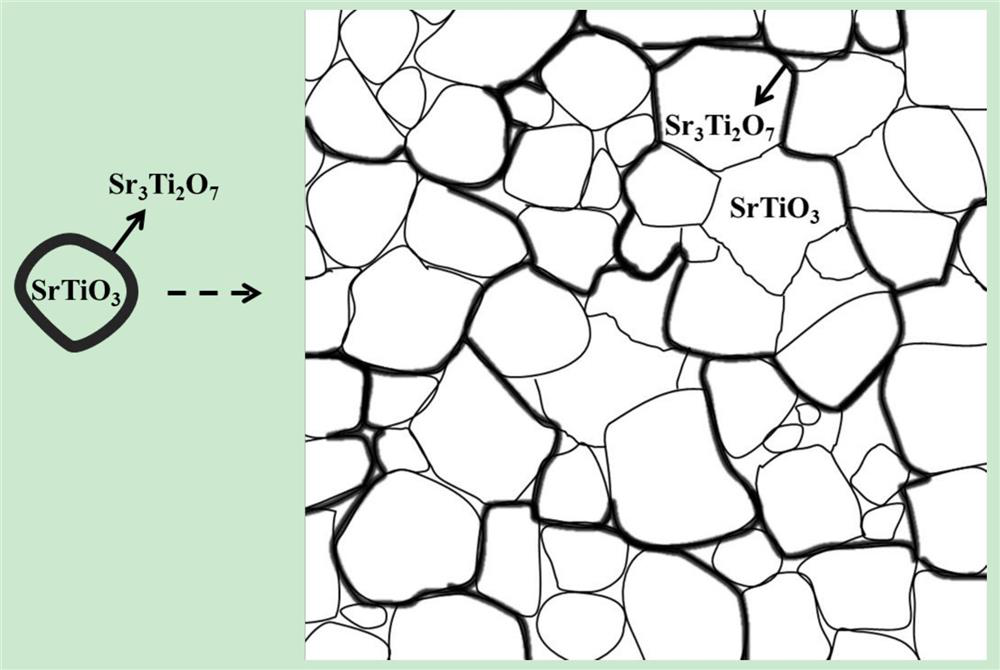

A technology of dielectric ceramics and insulating skeleton, which is applied in the field of insulating skeleton regulation of SrTiO3 dielectric ceramics, can solve the problems of complex process, poor stability of material parameters, small insulation resistivity, etc., and achieve simple preparation process, low equipment requirements, dielectric The effect of small electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

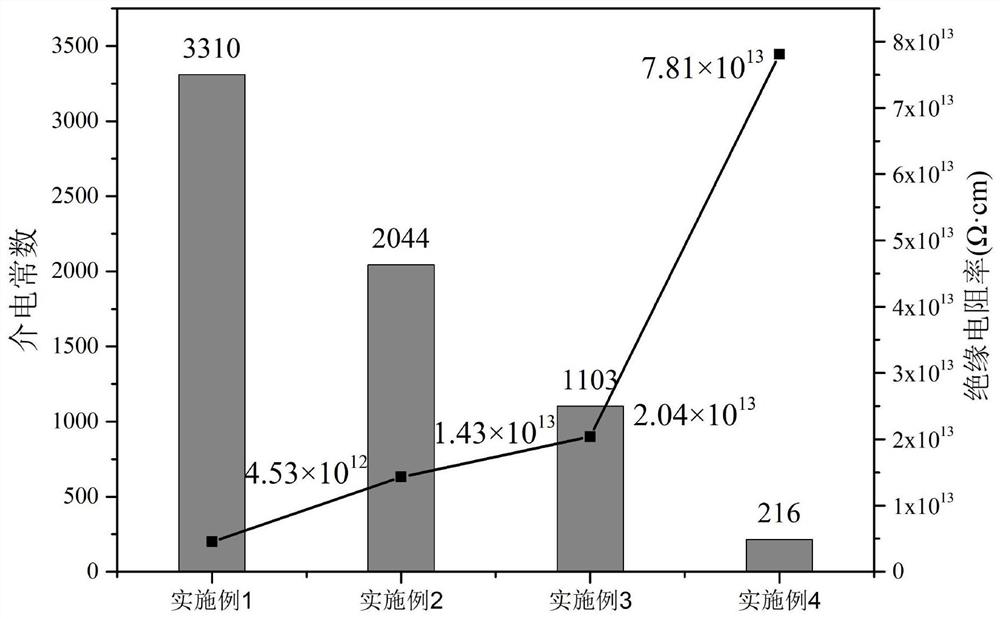

Embodiment 1

[0027] A High Dielectric, High Voltage SrTiO 3 The preparation method of dielectric ceramics comprises the following steps:

[0028] (1) First according to SrTiO 3 with Sr(NO 3 ) 2 The molar ratio is 100:1 to weigh 2.500g SrTiO 3 , 0.0288g Sr(NO 3 ) 2 , press Sr(NO 3 ) 2 The molar ratio to the complexing agent is 1:8, and 0.0655g of urea is weighed. Deionized water was used as solvent.

[0029] (2) Preparation of SrTiO 3 Stable suspension: Preparation of SrTiO using Triton X-100 as dispersant 3 Stable suspension. Add SrTiO to the beaker 3 Powder, pour in deionized water, and use a glass rod to stir to initially disperse SrTiO 3 After powder, add dispersant and continue to stir for 2min, then ultrasonically shake for 30min.

[0030] (3) Preparation of precursor-coated SrTiO 3 Composite powder: Sr(NO 3 ) 2 Dissolve in deionized water and add complexing agent urea. Add the prepared solution to the above SrTiO 3 In the stable suspension, stirred for 1 h in a con...

Embodiment 2

[0035] A High Dielectric, High Voltage SrTiO 3 The preparation method of dielectric ceramics comprises the following steps:

[0036] (1) First according to SrTiO 3 with Sr(NO 3 ) 2 The molar ratio of 100:1.5 weighs 2.500g SrTiO 3 , 0.0433gSr (NO 3 ) 2 , press Sr(NO 3 ) 2 The molar ratio to the complexing agent is 1:8, 0.0982 g of urea is weighed, and deionized water is used as the solvent.

[0037] (2) Preparation of SrTiO 3 Stable suspension: Preparation of SrTiO using Triton X-100 as dispersant 3 Stable suspension. Add SrTiO to the beaker 3 Powder, pour in deionized water, and use a glass rod to stir to initially disperse SrTiO 3 After powder, add dispersant and continue to stir for 2min, then ultrasonically shake for 30min

[0038] (3) Preparation of precursor-coated SrTiO 3 Composite powder: Sr(NO 3 ) 2 Dissolve in deionized water and add complexing agent urea. Add the prepared solution to the above SrTiO 3 The stable suspension was stirred in a constant ...

Embodiment 3

[0043] A High Dielectric, High Voltage SrTiO 3 The preparation method of dielectric ceramics comprises the following steps:

[0044] (1) First according to SrTiO 3 with Sr(NO 3 ) 2 The molar ratio is 100:2.5 to weigh 2.500g SrTiO 3 , 0.0721gSr(NO 3 ) 2 , press Sr(NO 3 ) 2 The molar ratio to the complexing agent is 1:8, 0.1637 g of urea is weighed, and deionized water is used as the solvent.

[0045] (2) Preparation of SrTiO 3 Stable suspension: Preparation of SrTiO using Triton X-100 as dispersant 3 Stable suspension. Add SrTiO to the beaker 3 Powder, pour in deionized water, and use a glass rod to stir to initially disperse SrTiO 3 After powder, add dispersant and continue to stir for 2min, then ultrasonically shake for 30min.

[0046] (3) Preparation of precursor-coated SrTiO 3 Composite powder: Sr(NO 3 ) 2 Dissolve in deionized water and add complexing agent urea. Add the prepared solution to the above SrTiO 3 The stable suspension was stirred in a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com