Polymerizable nonionic surfactant containing adamantane structure and preparation method thereof

A technology of non-ionic surfactants and active agents, applied in the field of polymerizable non-ionic surfactants and their preparation, to achieve good water solubility and expand the types and scope of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

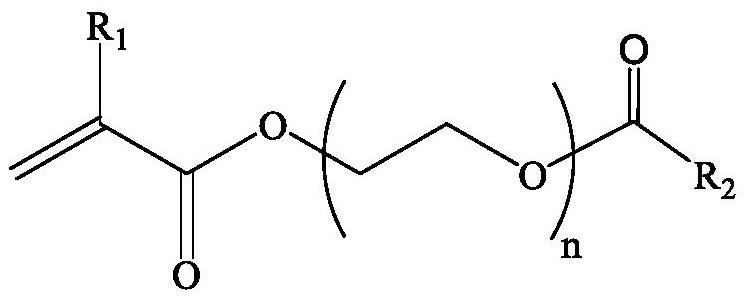

[0031] The present embodiment provides a preparation method of an adamantane structure-containing polymerizable nonionic surfactant, which is specifically as follows:

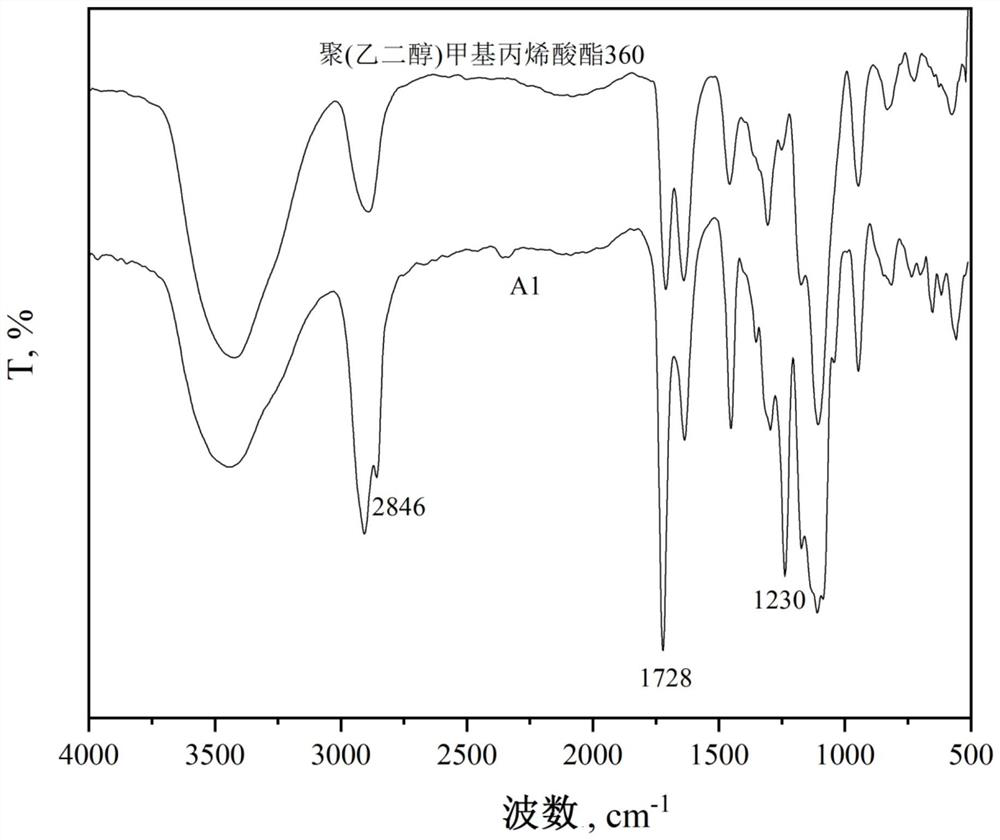

[0032] Under ice-water bath conditions, take 3.6 g of polyethylene glycol methacrylate (Mw=360, CAS number: 25736-86-1) and 2 g of 1-adamantanecarbonyl chloride, add them into 50 mL of dichloromethane, and after stirring evenly, A dichloromethane solution containing 1.05 g of triethylamine was slowly added dropwise, and after stirring for 4 h, the precipitate was removed by filtration, washed twice with 20 mL of 1% sodium bicarbonate solution and 1% hydrochloric acid in turn, and then separated. Then the oily liquid obtained is the product methacrylate polyethylene glycol 360 adamantyl methyl ester, which is named as A1. figure 1 It is the infrared contrast spectrum of the raw material polyethylene glycol methacrylate and the product A1. Compared with the raw material, the 1728cm in A1 -1 The peak of ester car...

Embodiment 2

[0034] The present embodiment provides a method for preparing an adamantane structure-containing polymerizable nonionic surfactant, which is specifically as follows:

[0035] Under ice-water bath conditions, take 5 g of polyethylene glycol methacrylate (Mw=500) and 2 g of 1-adamantanecarbonyl chloride, add them to 50 mL of dichloromethane, and after stirring evenly, slowly add triethylamine 1.05 g dropwise. The dichloromethane solution was stirred for 4 hours, and the precipitate was removed by filtration. After washing twice with 20 mL of 1% sodium bicarbonate solution and 1% hydrochloric acid, the liquid was separated. Ester polyethylene glycol 500 adamantyl methyl ester.

Embodiment 3

[0037] The present embodiment provides a method for preparing an adamantane structure-containing polymerizable nonionic surfactant, which is specifically as follows:

[0038] Take 3.6 g of polyethylene glycol methacrylate (Mw=360) and 1.8 g of 1-adamantanecarboxylic acid, add them to 50 mL of tetrahydrofuran, stir evenly, and slowly dropwise add a dichloromethane solution containing 1.5 g of thionyl chloride, After refluxing at 60°C for 4 hours, the solvent was evaporated to dryness, then ethyl acetate was added to dissolve it, washed twice with a mixture of sodium bicarbonate and ice-water, and then the liquid was separated. Acrylate polyethylene glycol 360 adamantyl methyl ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com