High-initial-adhesion and high-temperature-resistant hot melt adhesive and preparation method thereof

A high-temperature and heat-resistant technology, used in polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of insufficient substrate wetting, slow coating speed, short opening time, etc. The effect of balanced softening point, high service temperature and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

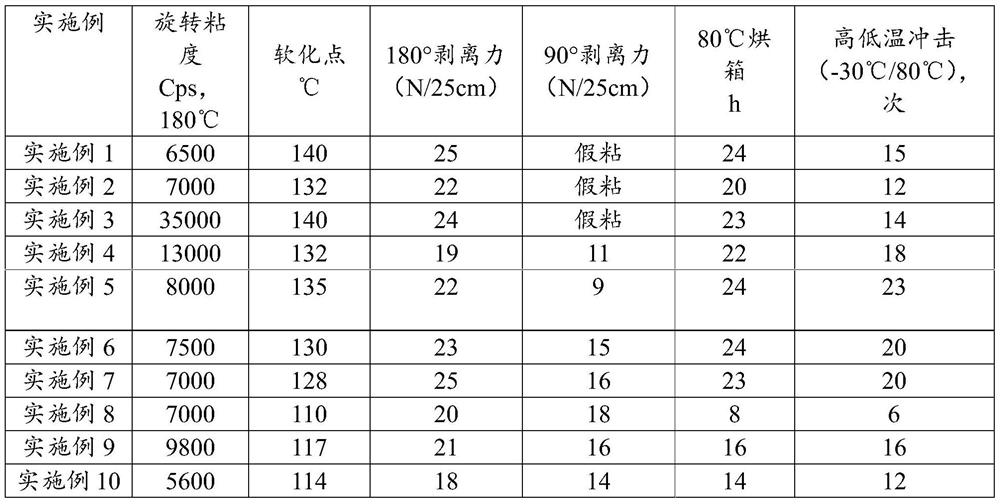

Examples

Embodiment 1

[0041] Embodiment 1 A first aspect provides a hot melt adhesive, in terms of mass percentage, the raw materials include: 10% of high-viscosity olefin resin, 30% of low-viscosity olefin resin, 25% of hydrogenated C5 petroleum resin, and 25% of hydrogenated DCPD resin , Polyisobutylene 9%, Antioxidant 1%.

[0042] Among them, the melt viscosity of the high-viscosity olefin resin is 45000cps at 190℃; the melt viscosity of the low-viscosity olefin resin is 8000cps at 190℃, and the tensile strength is 5.0MPa; the softening point of the high-viscosity olefin resin is 105℃; The softening point is 132℃, and the tensile strength is 1.5MPa.

[0043] In this example, the high-viscosity olefin resin was purchased from Evonik Chemical's 750 model high-viscosity olefin resin product; the low-viscosity olefin resin was purchased from Evonik's 308 model low-viscosity olefin resin product.

[0044] The softening point of the hydrogenated C5 petroleum resin is 100°C; the hydrogenation rate of ...

Embodiment 2

[0050] The specific implementation of this example is the same as that of Example 1, except that the high-viscosity olefin resin is 30% and the low-viscosity olefin resin is 10%.

Embodiment 3

[0052] The specific implementation of this example is the same as that of Example 1, except that the high-viscosity olefin resin is 25%, the low-viscosity olefin resin is 10%, and 5% of SIS rubber elastomer is also added.

[0053] In this example, the SIS rubber elastomer was purchased from the SIS1126 model product sold by Hunan Yuehua Chemical Industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com