Epitaxial wafer preparation method, epitaxial wafer and ultraviolet light-emitting diode

An epitaxial wafer, quantum technology, applied in the semiconductor field, can solve the problem of low quantum efficiency, and achieve the effect of increasing hole concentration, improving internal quantum efficiency, and blocking electron overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

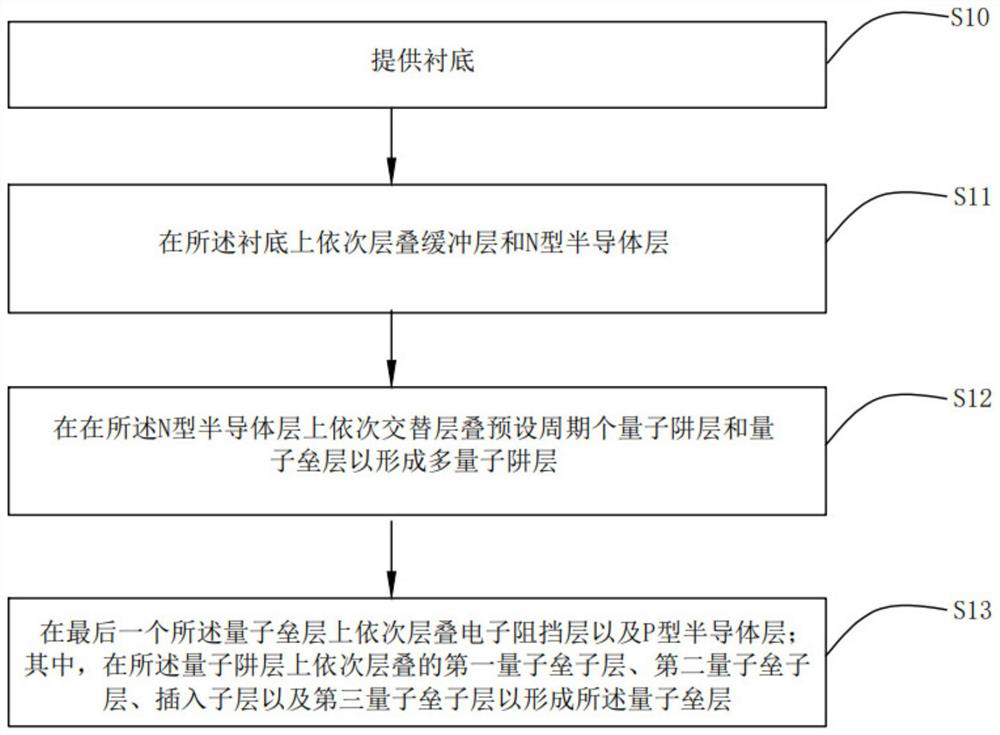

[0034] see figure 1 , is the method for preparing an epitaxial wafer proposed in the first embodiment of the present invention, and the method for preparing an epitaxial wafer includes steps S10 to S11 .

[0035] Step S10, providing a substrate.

[0036] Among them, the substrate includes but is not limited to sapphire, SiC, Si-based, and GaN. In this embodiment, the substrate is a Si-based substrate. The Si-based substrate has the advantages of good thermal conductivity, low cost, mature technology, and easy peeling. .

[0037] In step S11, a buffer layer and an N-type semiconductor layer are sequentially stacked on the substrate.

[0038] Specifically, in this embodiment, the buffer layer adopts an AlN layer.

[0039] Step S12, sequentially stacking a predetermined period of quantum well layers and quantum barrier layers alternately on the N-type semiconductor layer to form multiple quantum well layers.

[0040] The number of preset cycles can be set according to actual ...

Embodiment approach

[0048] More specifically, in order to clearly understand the specific implementation process of the present invention, the specific growth process of the entire epitaxial wafer is described in detail below, which is an embodiment of the present invention, but the growth process of the epitaxial wafer of the present invention is not limited to this. It does not constitute a limitation of the present invention.

[0049] Put the substrate in the MOCVD reaction chamber, pass TMAl and NH into the reaction chamber 3 , AlN layer is obtained by preparing AlN thin film by chemical vapor deposition method. Specifically, in this embodiment, the growth temperature of the AlN layer is 1250°, the growth thickness is about 1.5 μm, and the growth pressure is 50 mbar.

[0050] The main purpose of growing the high temperature AlN layer is to release the lattice mismatch and thermal mismatch between the substrate and the AlGaN material. Therefore, in this embodiment, the layer adopts NH under t...

Embodiment 2

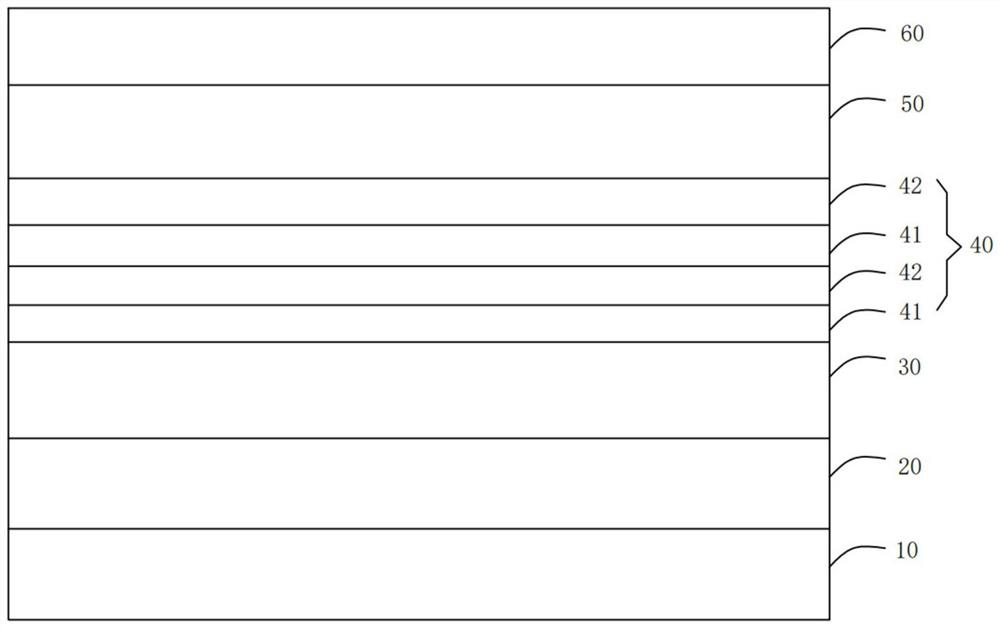

[0057] see Figure 2 to Figure 3 , shows the epitaxial wafer proposed in the first embodiment of the present invention, the epitaxial wafer is prepared by the epitaxial wafer preparation method in the above-mentioned first embodiment, and the epitaxial wafer includes:

[0058] The substrate 10 , the buffer layer 20 , the N-type semiconductor layer 30 , the multiple quantum well layer 40 , the electron blocking layer 50 and the P-type semiconductor layer 60 epitaxially grown on the substrate 10 in sequence.

[0059] Preferably, the buffer layer is an AlN layer, and the N-type semiconductor layer 30 is N-type doped Al x Ga (1-x) N layer, the electron blocking layer 50 is Al y Ga (1-y) N layer, P-type semiconductor layer 60 is P-type doped Al z Ga (1-z) N layers.

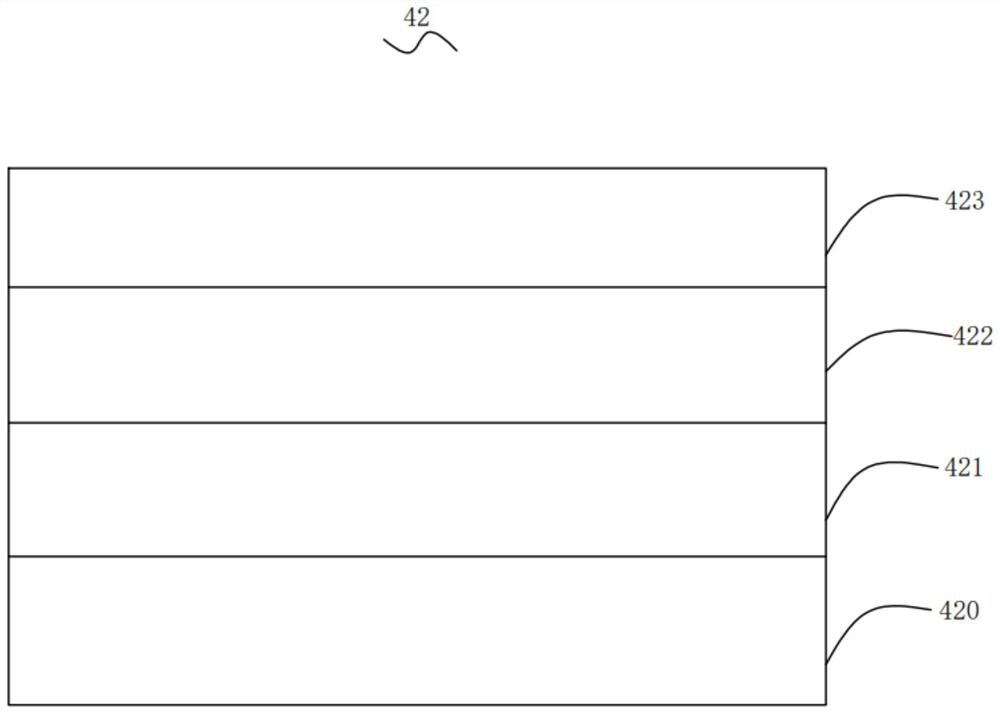

[0060] The multiple quantum well layer 40 includes quantum well layers 41 and quantum barrier layers 42 that are alternately stacked periodically. Specifically, the number of periods can be set according to the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com