Hyperbranched polymer plugging type anti-collapse agent, water-based drilling fluid containing hyperbranched polymer plugging type anti-collapse agent and preparation

A technology of hyperbranched polymer and water-based drilling fluid, which is applied in the preparation of organic compounds, the preparation of cyanide reaction, the composition of drilling holes, etc., to achieve the effects of good compatibility, low price and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment prepares a hyperbranched polymer plugging and anti-slump agent, comprising the following steps:

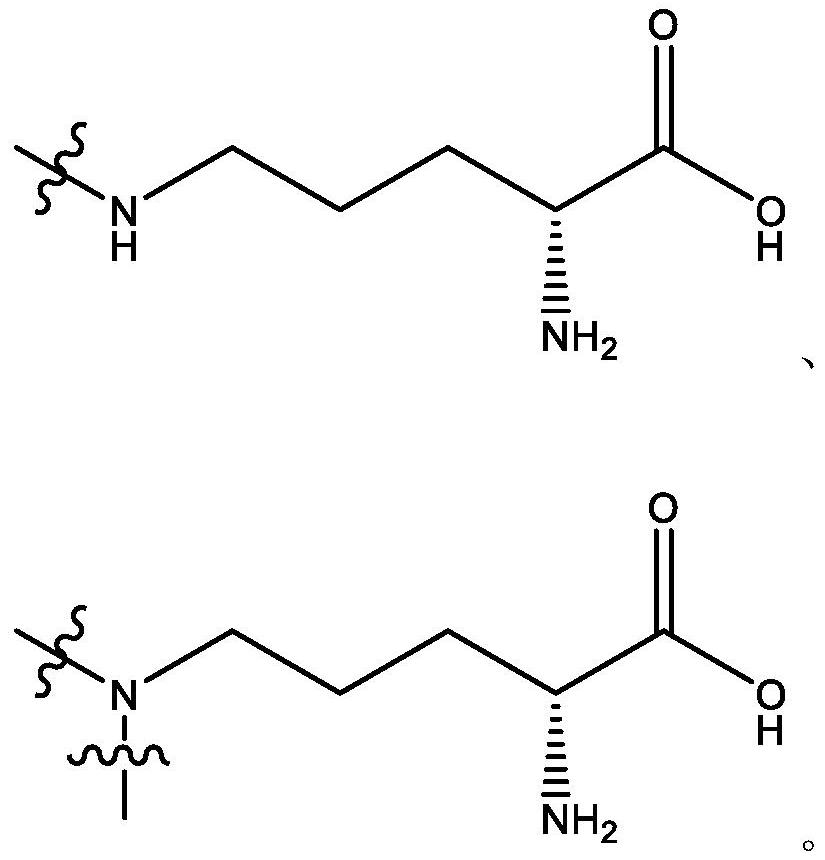

[0049] (1) Weigh 26.418g of ornithine and dissolve it in 160mL of a mixed solvent of methanol and water (volume ratio is 1:1), and transfer it to a three-necked flask with a thermometer, a mechanical stirring device and continuous nitrogen flow, and then add 19.8216g ethylene glycol dimethacrylate was stirred and refluxed for 16h at 105°C. After the reaction was completed, the solvent was removed by rotary evaporation (vacuum degree -0.09MPa) at 50°C until no liquid dripped within 5min to obtain a crude solution. Product A1.

[0050] (2) The crude product A1 is washed 3 to 4 times with methanol whose volume is 5-10 times the volume of A1 in a pear-shaped separatory funnel to remove the milky white viscous substance. Rotary evaporation at 40°C (vacuum degree - 0.09MPa) to remove methanol until no liquid drips within 5 min to obtain a bright yellow visco...

Embodiment 2

[0053] The present embodiment changes the raw material dosage ratio on the basis of Example 1, comprising the following steps:

[0054] (1) Dissolve 13.2090g of ornithine in 80mL of a mixed solvent of methanol and water (volume ratio is 1:1), and transfer it to a three-necked flask with a thermometer, a mechanical stirring device and continuous nitrogen flow, and then add 19.8216g ethylene glycol dimethacrylate was stirred and refluxed for 16h at 105°C. After the reaction was completed, the solvent was removed by rotary evaporation (vacuum degree -0.09MPa) at 50°C until no liquid dripped within 5min to obtain a crude solution. Product A2.

[0055] (2) The crude product A2 is washed 3 to 4 times with methanol whose volume is 5-10 times the volume of A2 in a pear-shaped separatory funnel to remove the milky white viscous substance. Rotary evaporation at 40° C. (vacuum degree-0.09MPa) to remove methanol until no liquid drips within 5 min to obtain a bright yellow viscous product...

Embodiment 3

[0060] In this example, the performance test of the hyperbranched polymer plugging anti-slump agent obtained in Example 2 is carried out.

[0061] In order to further illustrate the plugging effect of the hyperbranched polymer plugging anti-slump agent of the present invention, in this example, after compounding the plugging agent with the drilling fluid base slurry, the rheological properties and high temperature fluid loss properties were tested to illustrate the The blocking effect of the present invention.

[0062] 1. Preparation of water-based drilling fluid base slurry

[0063] 1) Bentonite pre-hydration treatment, the specific method is as follows: measure 10L of tap water, heat up to 65 ° C, under the condition of low-speed stirring, add 500g bentonite, after stirring for 10min, add 25g Na 2 CO 3 , stirred for 30min, sealed and let stand for 24h to obtain pre-hydrated bentonite slurry.

[0064] 2) Take 400mL of the pre-hydrated bentonite slurry prepared in step 1) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

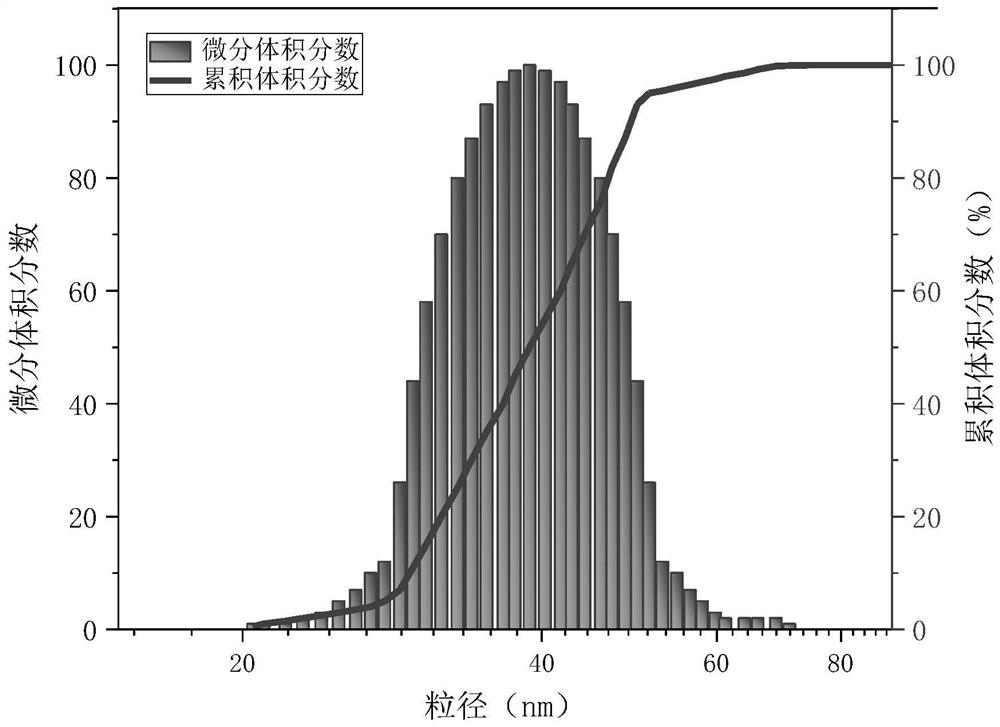

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com