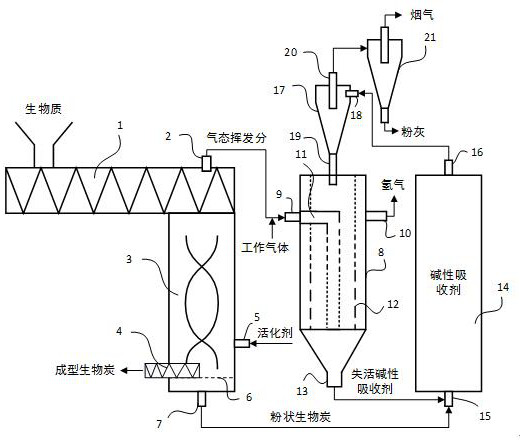

Method and system for hydrogen production and biochar co-production through biomass pyrolysis gasification

A technology of pyrolysis gasification and biochar, applied in combustible gas purification, combustible gas purification/transformation, hydrogen separation, etc., can solve the problems of energy consumption and treatment cost advantages, catalyst carbon deposition inactivation, and affecting process effectiveness and other problems, to achieve the effect of reducing the dust carried by the gas, uniformly dispersing the gas flow, and solving the large fluctuation of the pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The larch molding raw material with a size of 20mm was sent into the microwave pyrolysis reactor, and the microwave power density of the microwave pyrolysis reactor was set to 1 × 10 5 W / m 3 , the temperature is 700 ℃, react in the microwave pyrolysis reactor for 10 minutes, the generated gaseous volatile matter is discharged from the gaseous volatile matter outlet, and the generated biocoke falls into the gasification reactor by gravity; Under the action of passing the activator water vapor and stirring, the biocoke was heated to 800℃, the reaction time was 20 minutes and the power density was 2×10 5 W / m 3 Activated under conditions, the water vapor flow is controlled at 2m 3 / h, the gas product generated during the activation process is discharged from the gaseous volatile outlet, and the generated biochar is divided into two parts, of which the formed biochar as a product accounts for 40wt% of the biochar, with a specific surface area of 800m 2 / g, this part of ...

Embodiment 2

[0050] The larch molding raw material with a size of 10mm was sent into the microwave pyrolysis reactor, and the microwave power density of the microwave pyrolysis reactor was set to 2 × 10 5 W / m 3 , the temperature is 800 ° C, the reaction is carried out in the microwave pyrolysis reactor for 20 minutes, the generated gaseous volatiles are discharged from the gaseous volatiles outlet, and the generated biocoke falls into the gasification reactor by gravity; the biological coke falling into the gasification reactor Under the action of introducing activator water vapor and oxygen and stirring, the coke was heated to 850℃, the reaction time was 20 minutes and the power density was 2×10 5 W / m 3 Activated under conditions, the water vapor flow is controlled at 1m 3 / h, the oxygen flow is controlled at 0.1m 3 / h, the gas product generated during the activation process is discharged from the gaseous volatile outlet, and the generated biochar is divided into two parts, of which th...

Embodiment 3

[0052] The larch molding raw material with a size of 10mm was sent into the microwave pyrolysis reactor, and the microwave power density of the microwave pyrolysis reactor was set to 2 × 10 5 W / m 3 , the temperature is 800 ° C, the reaction is carried out in the microwave pyrolysis reactor for 20 minutes, the generated gaseous volatiles are discharged from the gaseous volatiles outlet, and the generated biocoke falls into the gasification reactor by gravity; the biological coke falling into the gasification reactor Under the action of introducing activator water vapor and oxygen and stirring, the coke was heated to 850℃, the reaction time was 20 minutes and the power density was 2×10 5 W / m 3 Activated under conditions, the water vapor flow is controlled at 1m 3 / h, the oxygen flow is controlled at 0.1m 3 / h, the gas product generated during the activation process is discharged from the gaseous volatile outlet, and the generated biochar is divided into two parts, of which th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com