Heterogeneous Fenton catalyst LaFeO3/3DOMCeO2 as well as preparation method and application thereof

A heterogeneous Fenton and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low utilization rate, narrow application range, and large iron slime production, etc. Achieve low Fe leaching concentration, solve the effect of narrow pH application range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

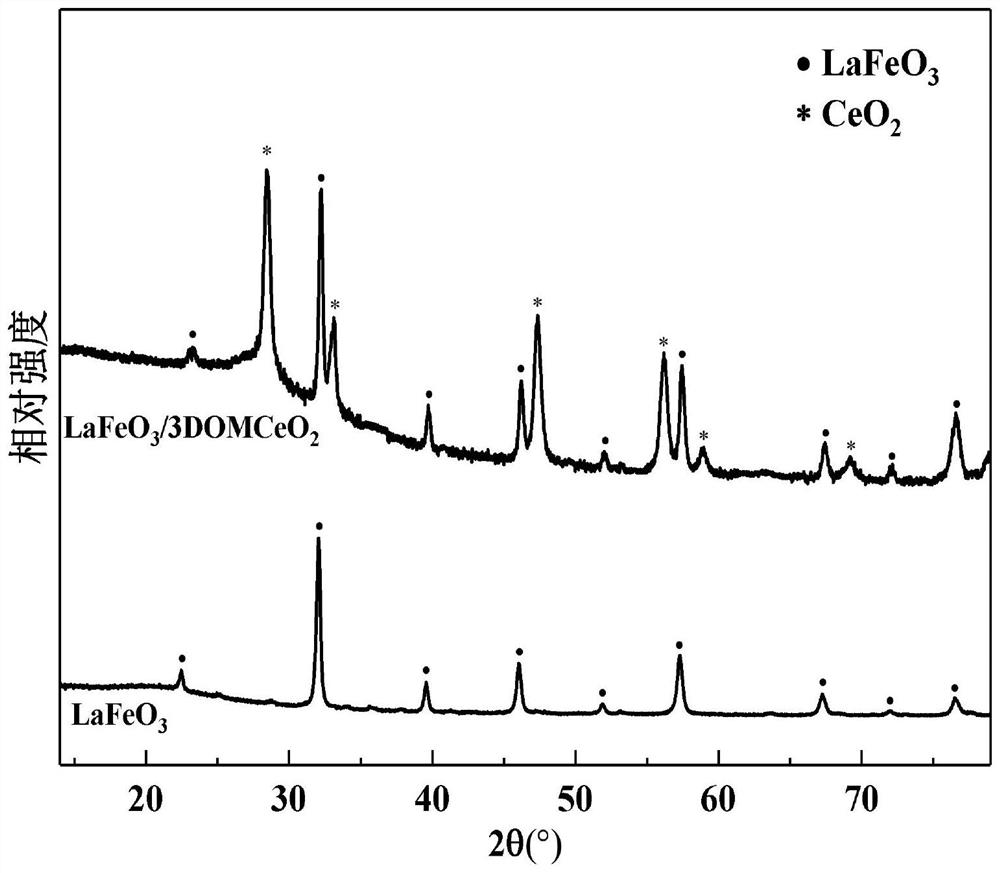

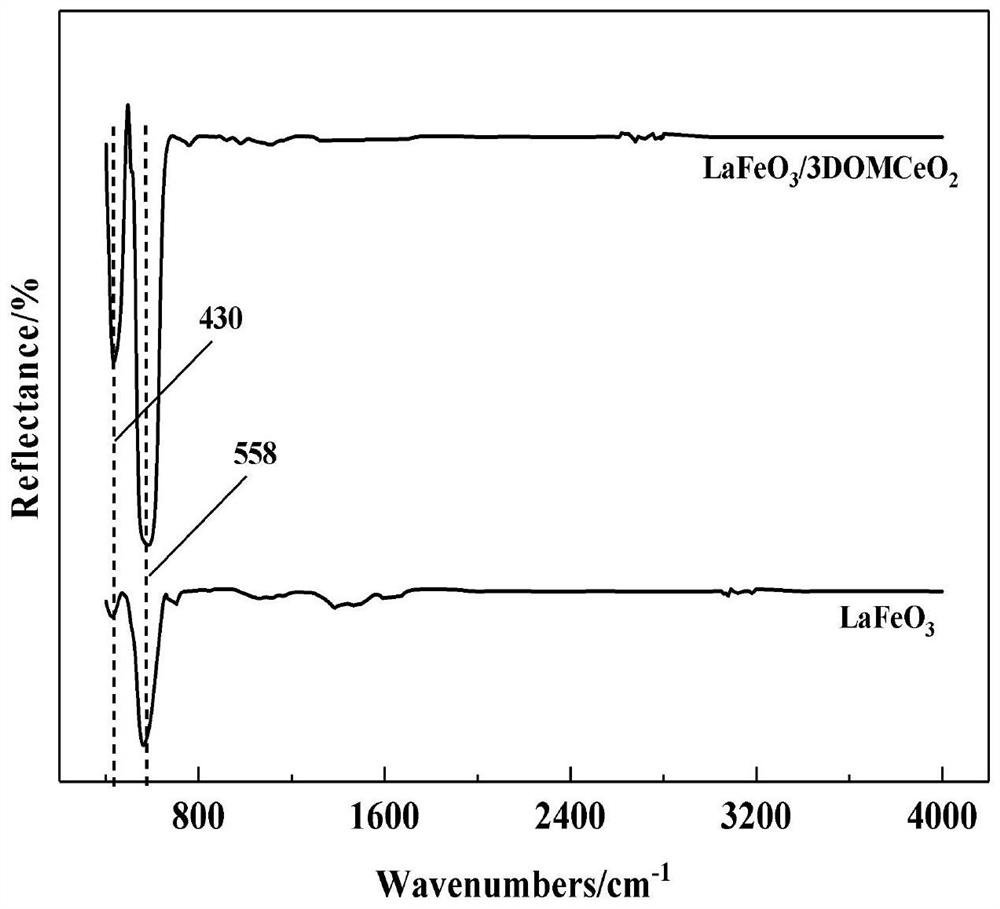

[0046] This example prepares a heterogeneous Fenton catalyst LaFeO 3 / 3DOMCeO 2 , the catalyst is based on three-dimensional ordered macroporous ceria (3DOMCeO 2 ) as the carrier material, with LaFeO 3 It is a composite catalyst of catalytically active components. Its preparation method is as follows:

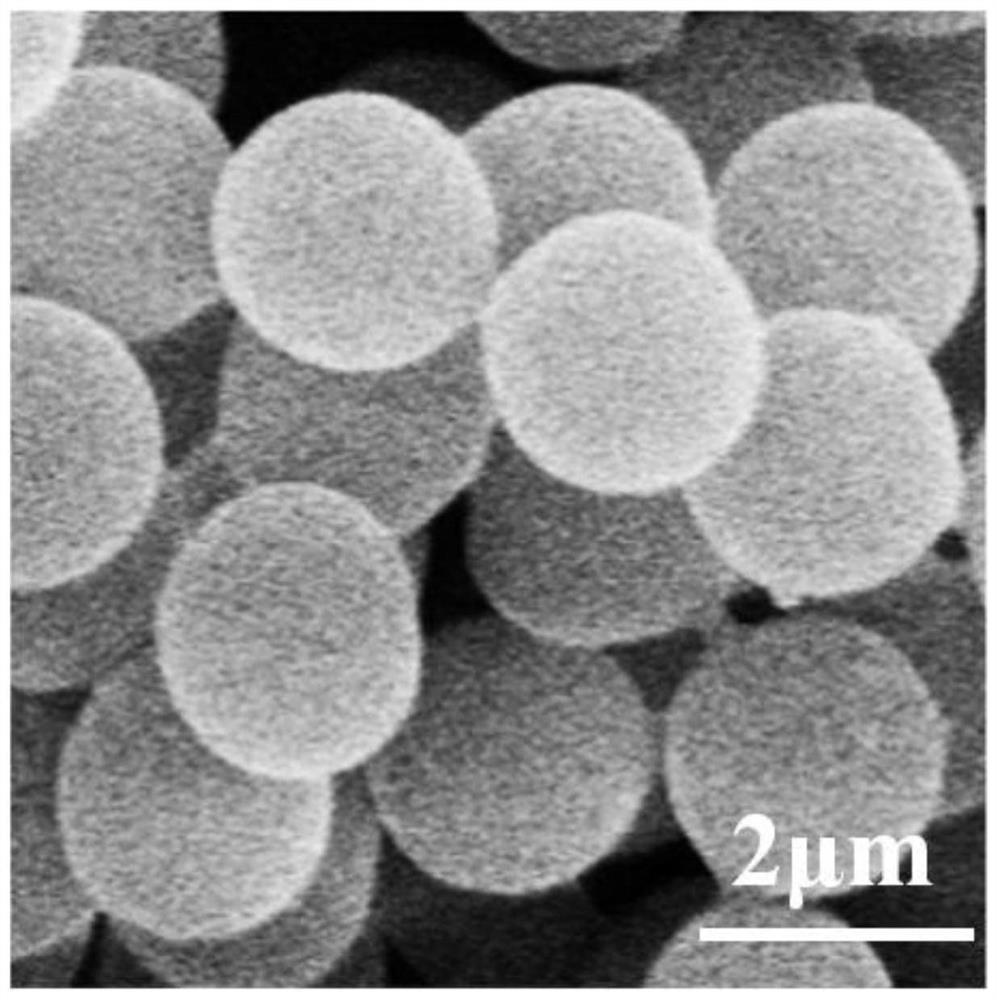

[0047] (1) Add 3 mL of deionized water, 1 mL of glacial acetic acid, 3 g of cerium source and 5 g of PMMA microspheres (2 μm in diameter) to 20 mL of absolute ethanol, ultrasonicate for 30 min, keep stirring, evaporate the water at 60 °C to gel and then dry A carrier precursor is obtained.

[0048] (2) The carrier precursor was placed in a tube furnace, and calcined at 500 °C for 3 h and 800 °C for 5 h in an air atmosphere to obtain three-dimensional ordered macroporous ceria 3DOMCeO 2 .

[0049] (3) Dissolve 8.66g lanthanum salt (lanthanum nitrate hexahydrate), 8.07g iron salt (iron nitrate nonahydrate) and 8.40g citric acid (molar ratio 1:1:2) in 200mL deionized water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com