Aluminum-magnesium layered composite material added with middle layer and preparation method of aluminum-magnesium layered composite material

A layered composite material and composite material technology, which is applied in the field of aluminum-magnesium layered composite materials with Ni interlayer and its preparation, can solve the problem that the interfacial bonding strength of aluminum-magnesium composite materials needs to be improved, and there are few researches on powder metallurgy aluminum-magnesium composite materials , affecting interface bonding performance and other issues, to achieve the effect of increasing shear strength, reducing production costs and improving shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

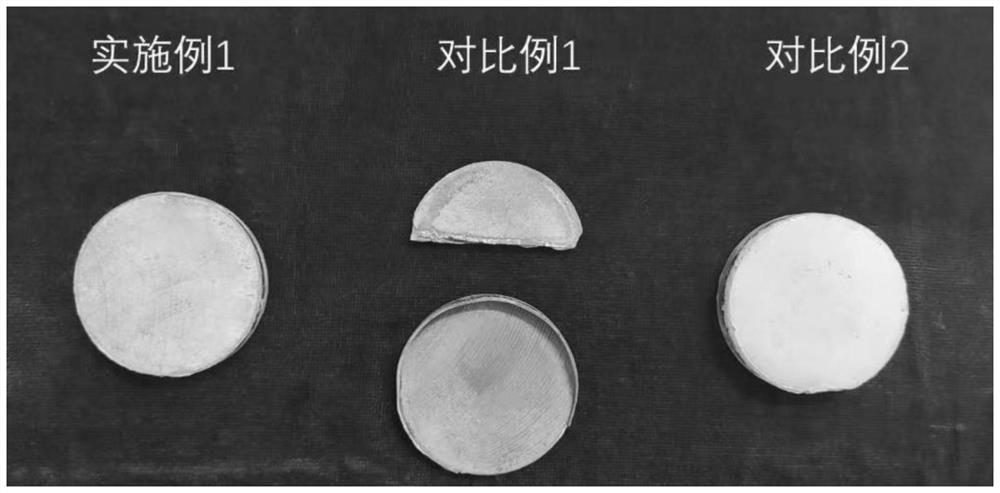

Embodiment 1

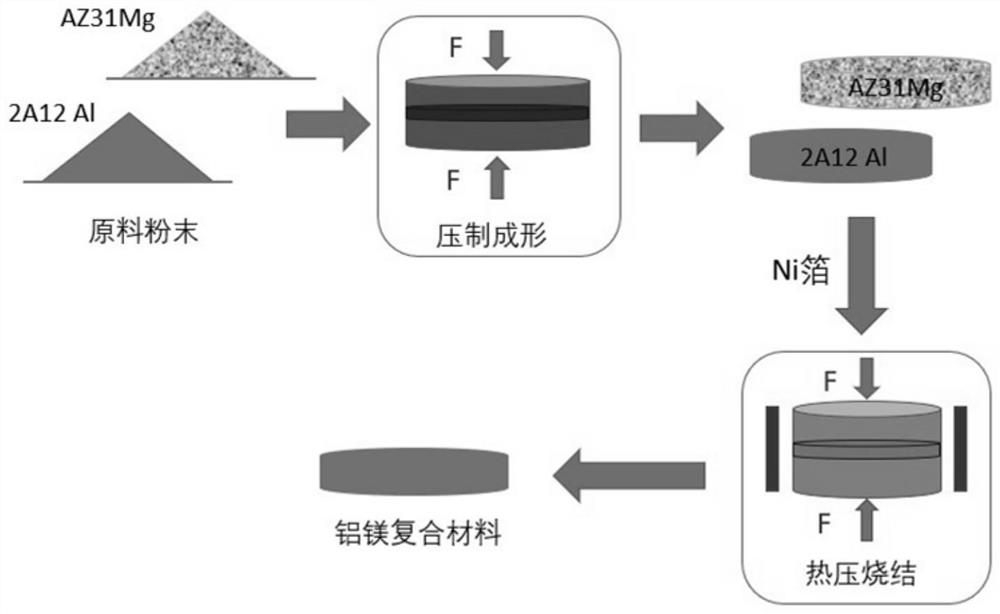

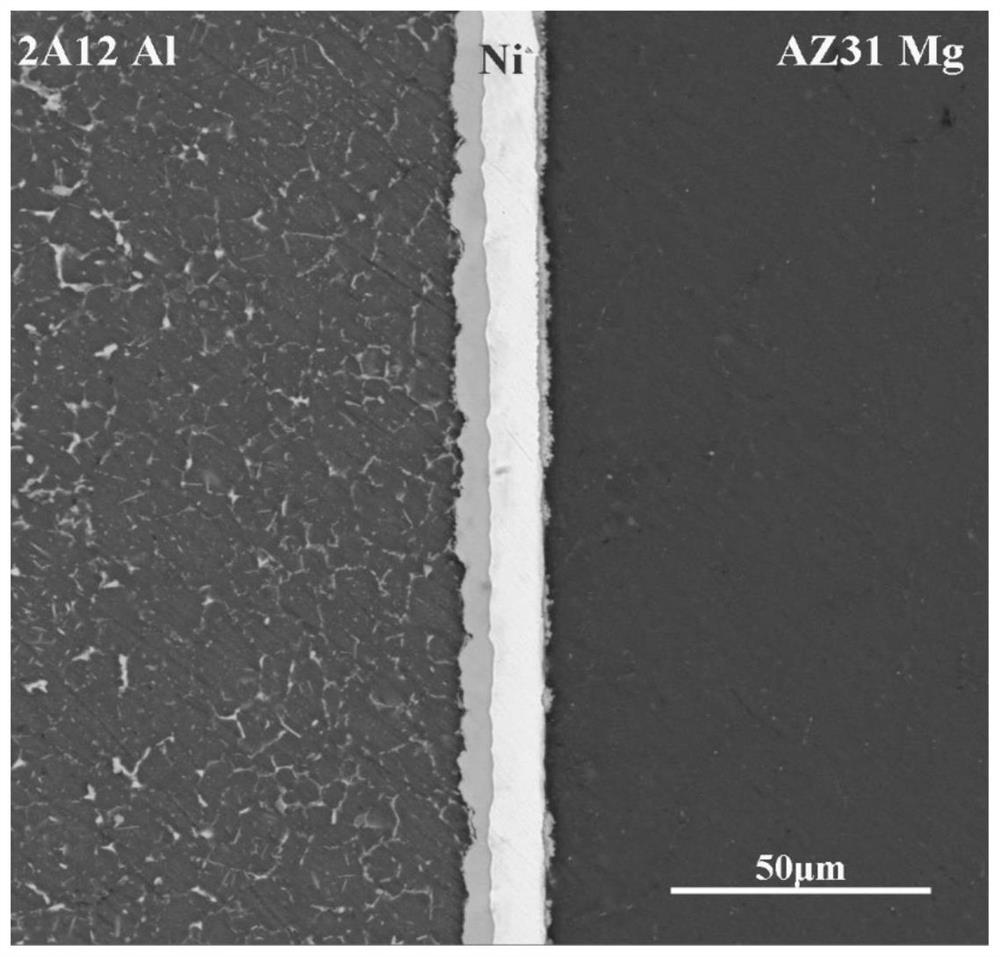

[0049] (1) Press 2A12 aluminum alloy powder and AZ31 magnesium alloy powder into a circular green body with a diameter of 40 mm under a pressure of 200 MPa, respectively; the particle size distribution of the aluminum alloy powder used is 5-100 microns, and the average particle size is 29.5 microns; The particle size distribution of the magnesium alloy powder used is 30-100 microns, and the average particle size is 68.6 microns;

[0050] (2) After using 1500# and 2000# water-grinding paper to surface-treat the pure Ni foil with a thickness of about 10 microns, clean it in an ultrasonic cleaner for 10 minutes, and take it out for drying; the thickness of the Ni foil is about 9 microns at this time;

[0051] (3) the dried Ni foil is placed between the aluminum-magnesium green bodies, and is put into the graphite mold;

[0052] (4) Put the graphite mold with the sample into the vacuum sintering furnace, and evacuate to 2*10 -2 After Pa, the heating was started, firstly, the temp...

Embodiment 2

[0054] Example 2 (using 20μm thick Ni-Cr-Fe alloy):

[0055] Other conditions are the same as in Example 1, except that a 20 μm thick Ni-Cr-Fe alloy foil is used.

[0056] The obtained aluminum-magnesium matrix is basically sintered and dense, and the tensile strength is about 205MPa, which reaches the normal level of aluminum-magnesium composite materials. The interface produces a certain amount of second phase structure, which affects the overall bonding strength of the interface. The shear strength of the material is slightly lower than that of the aluminum-magnesium composite material with pure Ni foil, which is about 55MPa.

Embodiment 3

[0058] Other conditions are the same as in Example 1, except that the aluminum alloy powder used is 7055Al alloy; the tensile strength of the obtained product is about 230MPa; the average shear strength of the product is about 57MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com