High-carbon-absorption early-strength cementing material based on recycled concrete powder and biochar and application of high-carbon-absorption early-strength cementing material

A technology of recycled concrete and cementitious materials, which is applied in the field of building materials, can solve the problems of reduced initial porosity, limited carbonation degree of materials, and high initial porosity of products, so as to improve carbon absorption capacity and early strength, reduce Effect of primary energy consumption and promotion of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

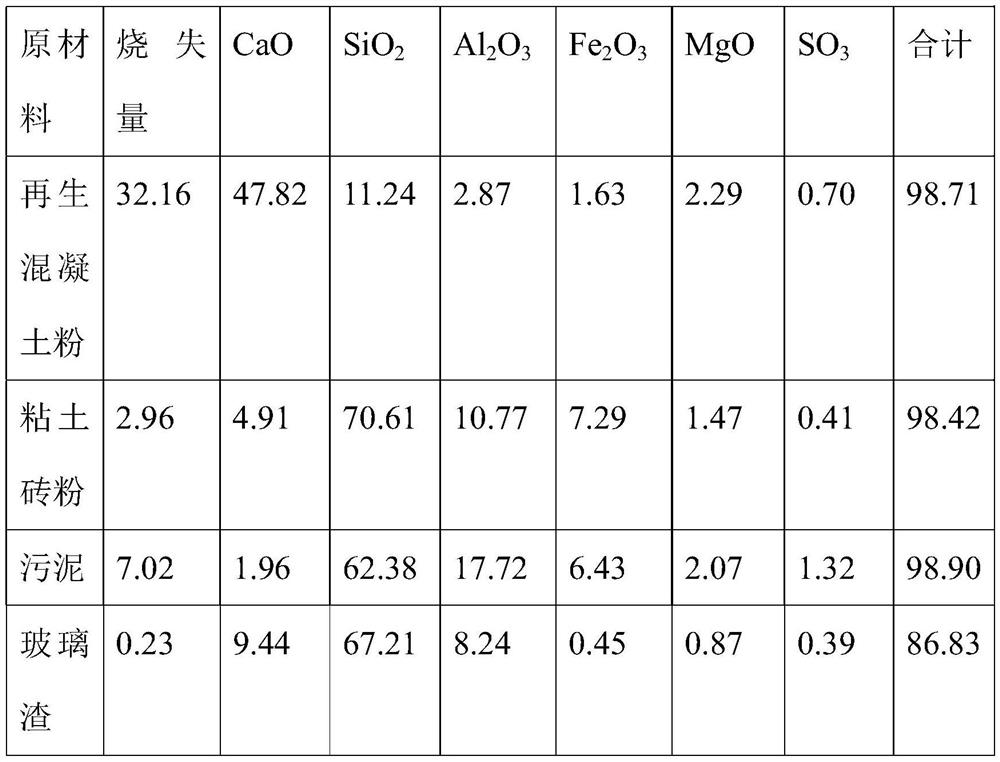

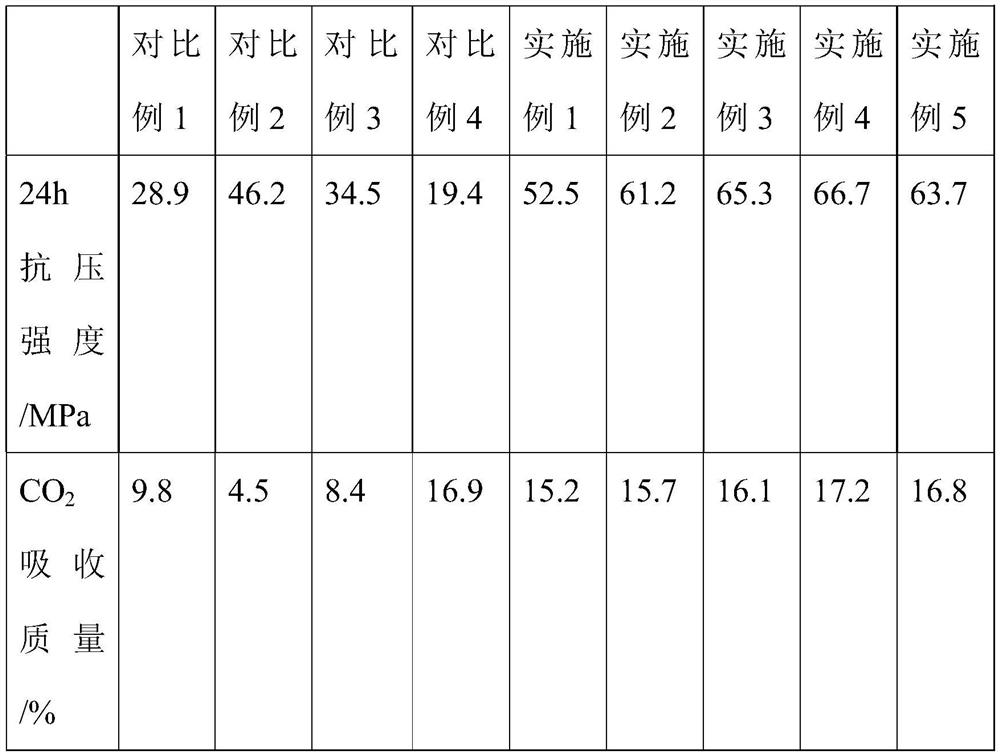

[0040] Weigh 87.8wt% recycled concrete powder and 12.2wt% sludge, mix and grind to a specific surface area of 250-350m 2 / kg, heat up to 850°C at a rate of 10°C / min, hold for 1 h; then heat up to 1250°C at a rate of 10°C / min, hold at a constant temperature for 3 hours; cool down to 525°C at a rate of 300°C / min, hold a constant temperature for 30 minutes, and then cool with the furnace to room temperature, and then ground to a specific surface area of 300-450m 2 / kg, to obtain γ-C 2 Carbon-absorbing cementitious material with S content of 56.7 wt%. The threshold of biochar volume dosage is V thre =7.47+2.01×2.0+0.13×172.42-0.0014×85.7×3.47 2 = 32.5%, the biochar used is straw charcoal, its average particle size is 172.42 μm, the porosity is 85.7%, and the average pore size is 3.47 μm, 1.1 times the V thre The carbon-absorbing cementitious material prepared by biochar and recycled concrete powder is mixed to form a high carbon-absorbing early-strength cementitious materi...

Embodiment 2

[0043] Weigh 88.1wt% recycled concrete powder and 11.9wt% clay brick powder, mix and grind to a specific surface area of 250-350m 2 / kg, heat up to 850°C at a rate of 10°C / min, hold for 1 h; then heat up to 1300°C at a rate of 10°C / min, and keep the temperature for 3 hours; cool down to 525°C at a rate of 300°C / min, keep the constant temperature for 30 minutes, and then cool with the furnace to room temperature, and then ground to a specific surface area of 300-450m 2 / kg, to obtain γ-C 2 Carbon-absorbing cementitious material with S content of 65.2 wt%. The threshold of biochar volume dosage is V thre =7.47+2.01×5.0+0.13×172.42-0.0014×85.7×3.47 2 = 38.5%, the biochar used is straw charcoal, its average particle size is 172.42 μm, the porosity is 85.7%, and the average pore size is 3.47 μm, 1.1 times the V thre The carbon-absorbing cementitious material prepared by biochar and recycled concrete powder is mixed to form a high carbon-absorbing early-strength cementitious...

Embodiment 3

[0046] Weigh 86.4wt% recycled concrete powder and 13.6wt% glass slag, mix and grind to a specific surface area of 250-350m 2 / kg, heat up to 900°C at a rate of 10°C / min, and hold for 0.5h; then heat up to 1350°C at a rate of 10°C / min, and keep the temperature for 2 hours; cool down to 525°C at a rate of 300°C / min, keep the temperature for 30 minutes, and then follow the furnace Cool to room temperature, then grind to a specific surface area of 300-450m 2 / kg, to obtain γ-C 2 Carbon-absorbing cementitious material with S content of 71.2 wt%. The threshold of biochar volume dosage is V thre =7.47+2.01×4.0+0.13×172.42-0.0014×85.7×3.47 2 = 36.5%, the biochar used is straw charcoal, its average particle size is 172.42 μm, the porosity is 85.7%, and the average pore size is 3.47 μm. thre The carbon-absorbing cementitious material prepared by biochar and recycled concrete powder is mixed to form a high carbon-absorbing early-strength cementitious material.

[0047] Mix 83.2w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com