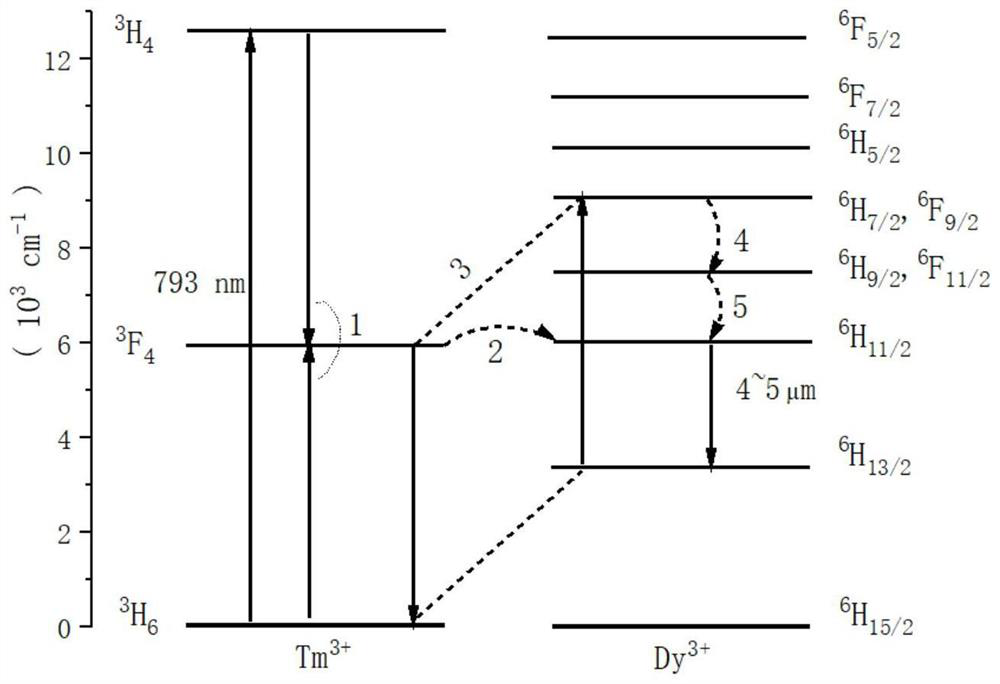

Thulium and dysprosium co-doped bromide mid-infrared laser crystal as well as preparation method and application thereof

A technology of infrared lasers and laser crystals, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of immature development of LD pump sources, poor stability, complex systems, etc., and achieve the suppression of laser self-termination bottlenecks effect, the effect of improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

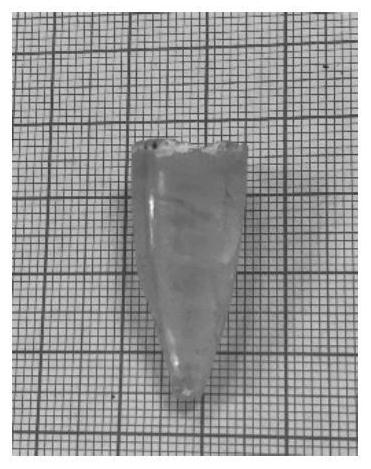

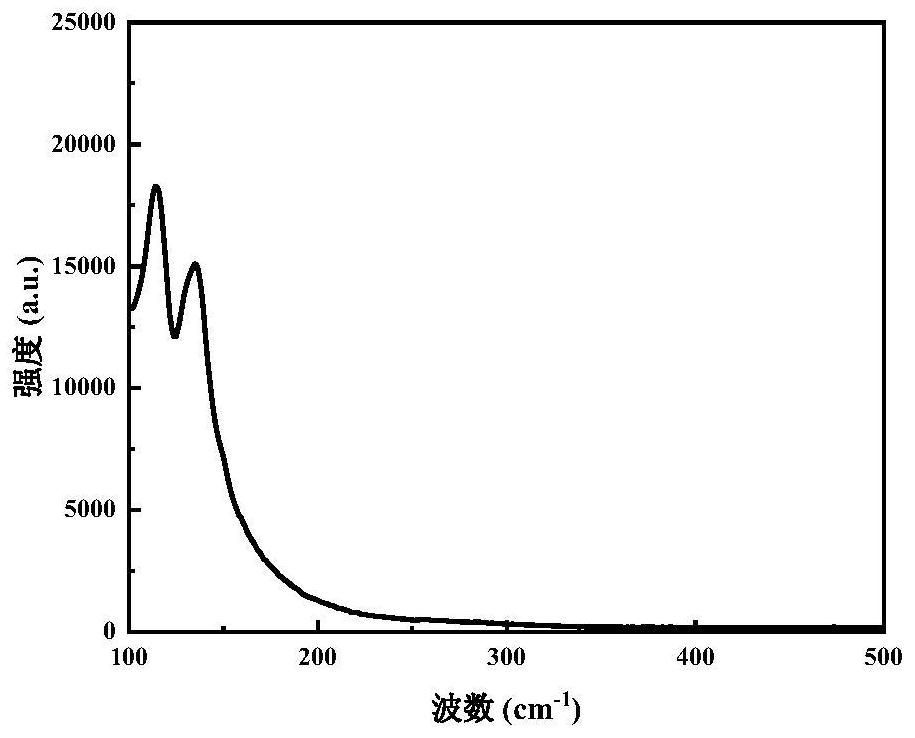

Embodiment 1

[0022] The metal element selects K element, selects x=0.01, y=0.001, and uses the crucible descending method to grow K (Tm 0.01 Dy 0.001 Pb 0.989 ) 2 Br 5 crystal. High-purity (5N) PbBr in a glove box 2 , KBr, DyBr 3 , TmBr 3 According to K(Tm 0.01 Dy 0.001 Pb 0.989 ) 2 Br 5 Molecular formula prepare 20g raw materials, mix them evenly and put them into a quartz crucible. Take out the quartz crucible containing the prepared raw materials from the glove box, evacuate it, and seal it with oxyhydrogen flame welding. Polycrystalline feedstocks were synthesized by sintering at 300°C for 10 hours. The quartz crucible containing the polycrystalline material was placed in the crucible descending method growth equipment to heat up to 390 °C, and the temperature was kept constant for 2 hours, and then the crystal growth was completed at a descending speed of 0.5 mm / h. Finally, after 5 hours, it was cooled to room temperature to obtain K (Tm 0.01 Dy 0.001 Pb 0.989 ) 2 Br...

Embodiment 2

[0024] The metal element selects Rb element, selects x=0.1, y=0.05, and uses the crucible descending method to grow Rb (Tm 0.1 Dy 0.05 Pb 0.85 ) 2 Br 5 crystal. High-purity (5N) PbBr in a glove box 2 , RbBr, DyBr 3 , TmBr 3 According to Rb(Tm 0.1 Dy 0.05 Pb 0.85 ) 2 Br 5 Molecular formula prepare 25g of raw materials, mix them evenly and put them into a quartz crucible. Take out the quartz crucible containing the prepared raw materials from the glove box, evacuate it, and seal it with oxyhydrogen flame welding. The polycrystalline starting material was synthesized by sintering at a temperature of 330°C for 8 hours. The quartz crucible containing the polycrystalline material was placed in the crucible descending furnace to heat up to 390°C, and the temperature was kept constant for 2 hours. Then, crystal growth was completed at a descending speed of 0.8 mm / h thereafter. Finally, after 5 hours, it was lowered to room temperature to obtain Rb(Tm 0.1 Dy 0.05 Pb 0...

Embodiment 3

[0026] The metal element selects Tl element, selects x=0.05, y=0.02, and uses the crucible descending method to grow Tl (Tm 0.05 Dy 0.02 Pb 0.93 ) 2 Br 5 crystal. The laser crystal growth, sample preparation and performance testing conditions are all used in Example 1, the difference is that the polycrystalline sintering temperature is 350 °C, the constant temperature time is 5 hours, and the crucible falling rate is 0.2 mm / h. A 793nm laser diode-pumped crystal was used to obtain a 4.3-micron band CW laser output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com