Nerve conduit loaded with gradient density particles and preparation method

A nerve conduit and gradient density technology, applied in prosthesis, single-component polyester artificial filament, medical science, etc., can solve the problems of low biological activity and slow repair speed of peripheral nerve damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Step (1). Dissolve polycaprolactone in dichloromethane, stir magnetically at room temperature for 24h, to obtain solution D with a mass concentration of 15%;

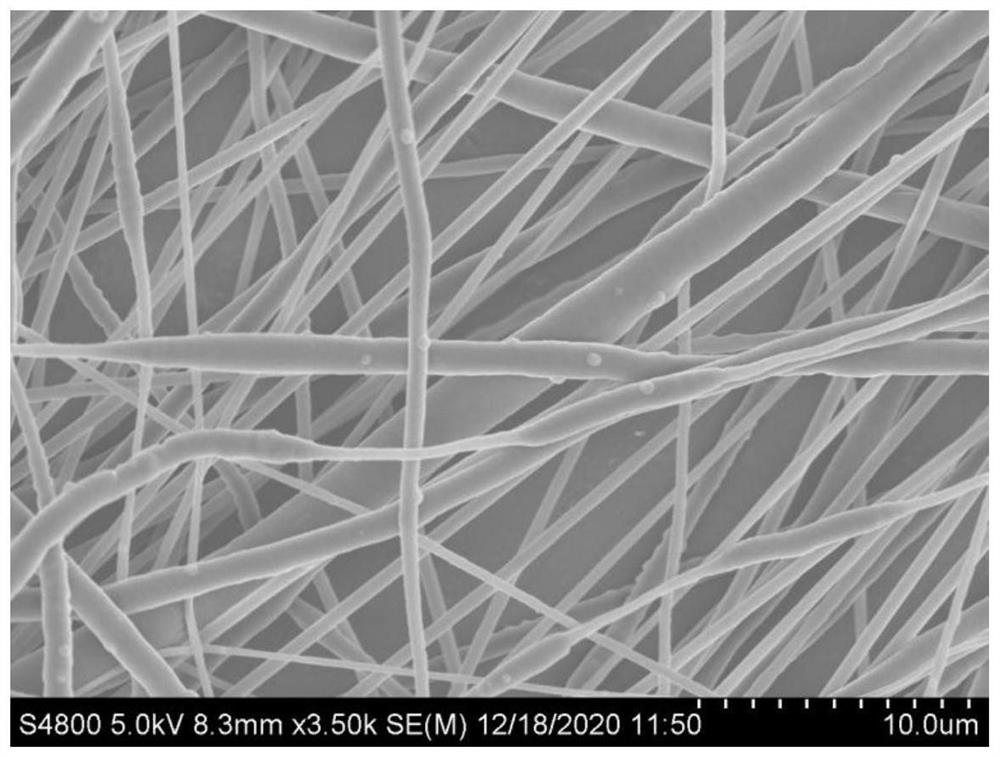

[0064] Step (2). Electrospinning with solution D, using a roller with a rotating speed of 1000 rpm as a receiver, solution D advancing rate of 8.0 mL / h, voltage of 19 kV, receiving distance of 18 cm, spinning for 1000 min, to obtain uniaxial orientation The polycaprolactone nanofiber membrane;

[0065] Step (3). Dissolve laminin and fibronectin in an aqueous acetic acid solution, stir magnetically at room temperature for 24 hours, and mix thoroughly to obtain a shell solution E with a concentration of 15 mg / mL; take vascular endothelial growth factor and add it to deionized water, Fully stirring and dissolving to obtain the core layer solution F, the concentration is 10ug / mL, the dosage ratio of the polycaprolactone fiber membrane to the sum of the shell layer solution and the core-shell solution is: 1g:40mL; the...

Embodiment 2

[0069] Step (1). Dissolve polylactic acid in trifluoroethanol, and stir magnetically at room temperature for 20h to obtain solution D with a mass concentration of 5%;

[0070] Step (2). Electrospinning with solution D, using a roller with a rotational speed of 2000rpm as a receiver, solution D advancing rate of 5.0mL / h, voltage of 16kV, receiving distance of 13cm, spinning for 1000min, to obtain uniaxial orientation PLA nanofiber membrane;

[0071] Step (3). Dissolve laminin in trifluoroethanol, stir with magnetic force at room temperature for 24 hours, and mix thoroughly to obtain shell solution E with a concentration of 35 mg / mL; take vascular endothelial growth factor and nerve growth factor and add them to deionized In water, fully stir and dissolve to obtain core layer solution F, the concentration is 50ug / mL, the dosage ratio of polylactic acid fiber membrane to the sum of shell layer solution and core-shell solution is: 1g:30mL; the dosage ratio of shell layer solution ...

Embodiment 3

[0075] Step (1). Dissolve polylactic acid-glycolic acid copolymer in chloroform and N,N'-dimethylformamide, and stir magnetically at room temperature for 8h to obtain solution D with a mass concentration of 8%;

[0076] Step (2). Electrospinning with solution D, using a roller with a rotating speed of 1500 rpm as a receiver, solution D advancing rate of 4.0 mL / h, voltage of 26 kV, receiving distance of 28 cm, spinning for 840 min, to obtain uniaxial orientation The polylactic acid-glycolic acid copolymer nanofiber membrane;

[0077] Step (3). Dissolve laminin in a sterile aqueous solution, and mix thoroughly with magnetic stirring at room temperature for 24 hours to obtain shell solution E with a concentration of 30 mg / mL; take brain-derived nerve growth factor, human acidic fibroblast growth The factor is added into deionized water, and the core layer solution F is obtained by stirring and dissolving sufficiently. The dosage ratio of shell solution and core solution is 4:1; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com