Environment-friendly water-based fire extinguishing agent and preparation method thereof

A fire extinguishing agent and water-based technology, applied in fire prevention equipment, etc., can solve the problems of affecting the fire-extinguishing effect of water-based fire extinguishing agents, poor recombustion resistance, and low fire extinguishing level, and achieve good recombustion resistance, low surface tension, and fast fire extinguishing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

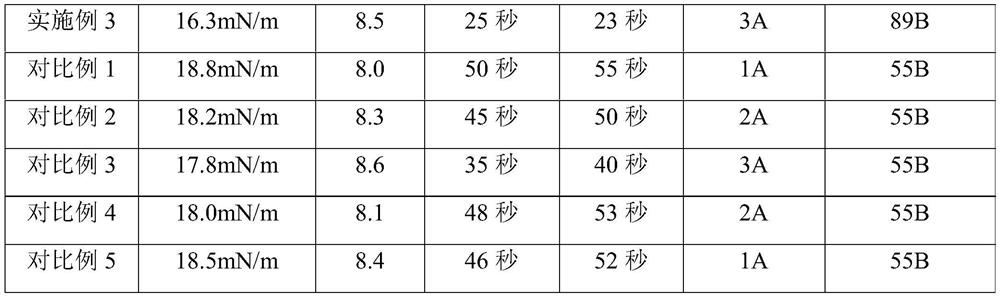

Examples

Embodiment 1

[0034] According to weight percentage, the water-based fire extinguishing agent in Example 1 is composed of 3% perfluoroalkyl amine oxide FSC-111, 3% perfluoroalkyl polyacrylamide YY-1069, 2% alkyl glycoside APG0810, 2% % of sodium decyl sulfate SDS1030, 10% of sodium N-lauryl-β-iminodipropionate 160C, 5% of dipropylene glycol monomethyl ether, 5% of ethylene glycol, 5% of urea, 5% of Ammonium polyphosphate and 60% water were prepared.

[0035] The concrete steps are: adding 60kg of water in the stirring tank, adding 5kg ammonium polyphosphate, 5kg ethylene glycol, 5kg urea, 5kg dipropylene glycol monomethyl ether, 2kg alkyl glycoside APG0810, 2kg successively under mechanical stirring at 300r / min Sodium decyl sulfate SDS1030, 10kg N-lauryl-β-iminodipropionate sodium 160C, 3kg perfluoroalkyl polyacrylamide and 3kg perfluoroalkylamine oxide were stirred for 30min. Finally, use sodium hydroxide or citric acid to adjust the pH value of the above mixture between 7 and 8, and cont...

Embodiment 2

[0037] According to weight percentage, the water-based fire extinguishing agent in Example 2 is composed of 5% perfluoroalkyl amine oxide FSC-111, 5% perfluoroalkyl polyacrylamide YY-1069, 3% alkyl glycoside APG0810, 3 % sodium decyl sulfate SDS1030, 9% sodium N-lauryl-β-iminodipropionate 160C, 6% dipropylene glycol monobutyl ether, 7% ethylene glycol, 10% urea, 8% Ammonium polyphosphate and 44% water were prepared.

[0038] The concrete steps are: adding 44kg of water in the stirring tank, adding 8kg ammonium polyphosphate, 7kg ethylene glycol, 10kg urea, 6kg dipropylene glycol monobutyl ether, 3kg alkyl glycoside APG0810, 3kg successively under mechanical stirring at 300r / min Sodium decyl sulfate SDS1030, 9kg N-lauryl-β-iminodipropionate sodium 160C, 5kg perfluoroalkyl polyacrylamide and 5kg perfluoroalkyl amine oxide were stirred for 30min. Finally, use sodium hydroxide or citric acid to adjust the pH value of the above mixture between 7 and 8, and continue stirring for 10...

Embodiment 3

[0040] In terms of weight percentage, the water-based fire extinguishing agent in Example 3 is composed of 8% perfluoroalkyl amine oxide FSC-111, 7% perfluoroalkyl polyacrylamide YY-1069, 4% alkyl glycoside APG0810, 5 % sodium decyl sulfate SDS1030, 10% sodium N-lauryl-β-iminodipropionate 160C, 10% dipropylene glycol monomethyl ether, 10% ethylene glycol, 12% urea, 5% Prepared from ammonium polyphosphate, 5% ammonium sulfate, and 24% water.

[0041]The concrete steps are: adding 24kg of water in the stirring tank, adding 5kg ammonium polyphosphate, 5kg ammonium sulfate, 10kg ethylene glycol, 12kg urea, 10kg dipropylene glycol monomethyl ether, 4kg alkyl group successively under mechanical stirring at 300r / min Glycoside APG0810, 5kg sodium decyl sulfate SDS1030, 10kg N-lauryl-β-iminodipropionate sodium 160C, 7kg perfluoroalkyl polyacrylamide and 8kg perfluoroalkylamine oxide were stirred for 30min. Finally, use sodium hydroxide or citric acid to adjust the pH value of the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com