Small titanium alloy additive manufacturing atmosphere protection device and using method thereof

A technology for additive manufacturing and protection devices, which is applied in the field of small-scale titanium alloy additive manufacturing atmosphere protection devices, can solve problems such as air leakage, low reliability of sealing devices, and film rupture, achieving low risk of air leakage, simple structure, The effect of safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Some technical terms appearing in the present invention are explained.

[0044] Micro positive pressure means that in a closed environment, the air pressure of the internal environment is slightly greater than the air pressure of the external atmospheric environment, so that the flow of gas is always from the inside to the outside, preventing the external impurity gas from entering the closed environment.

[0045] 1ppm means one part per million of the gas concentration.

[0046] PLC is the abbreviation of Programmable Logic Controller (Programmer Logic Controller).

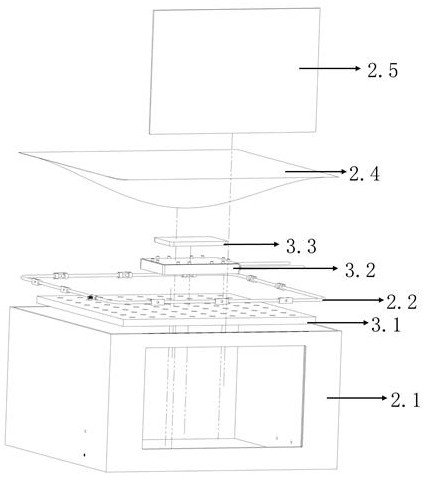

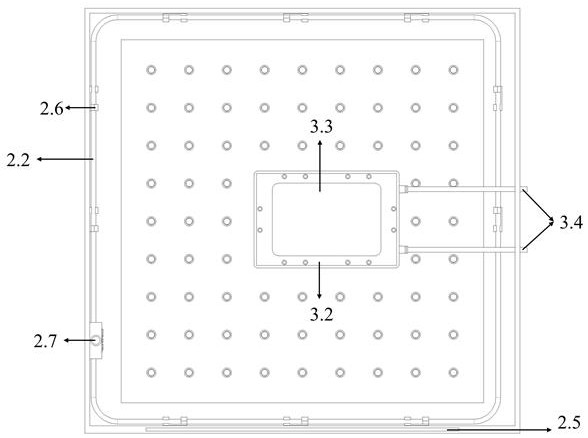

[0047] The invention provides a small titanium alloy additive manufacturing atmosphere protection device, such as Figure 1-2 As shown, it includes an acrylic box 2.1, a flow control box 4.1, and a PLC control box 4.2. The acrylic box 2.1 is provided with a water cooling device 3.2, a substrate 3.3, a laser cladding instrument and an oxygen concentration detector 2.7. The water cooling device 3.2 is used...

Embodiment 2

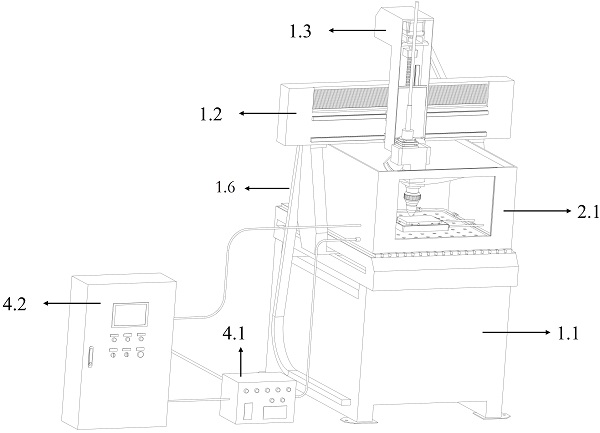

[0050] The present invention provides a small titanium alloy additive manufacturing atmosphere protection device. On the basis of Example 1, further, such as Figure 1-5 As shown, the acrylic box 2.1 is placed on the working platform 1.1, and the working platform 1.1 is provided with a moving device. The moving device includes an x-axis drive mechanism 1.6, a y-axis drive mechanism 1.2, and a z-axis drive mechanism 1.3. The x-axis drive mechanism 1.6 It is slidably connected to the working platform 1.1 and spans above the acrylic box 2.1, the y-axis drive mechanism 1.2 is slidably connected to the x-axis drive mechanism 1.6, and the z-axis drive mechanism 1.3 is slidably connected to the y-axis drive mechanism 1.2. The x-axis drive mechanism 1.6, the z-axis drive mechanism 1.3, and the y-axis drive mechanism 1.2 use conventional screw rods or pneumatic slide tables to adjust the spatial position of the laser head 1.4.

[0051] Further, the laser cladding apparatus is connected...

Embodiment 3

[0058] On the basis of Embodiment 2, the present invention provides a method for using a small-sized titanium alloy additive manufacturing atmosphere protection device, comprising the following steps:

[0059] Step 1. Place the acrylic box 2.1 on the surface of the working platform 1.1, put the bottom plate 3.1 into the bottom of the acrylic box 2.1, place the water-cooling device 3.2 in a suitable position on the bottom plate 3.1, and connect the water inlet pipe of the water-cooling device 3.2 And the return pipe is introduced to the outside through the small hole on the acrylic box 2.1, and the base plate 3.3 is placed on the water cooling base. The oxygen concentration detector 2.7 is fixed on the inner wall of the acrylic box 2.1, and the signal line is introduced to the outside through the holes in the acrylic box 2.1 to connect with the PLC control box 4.2.

[0060] Step 2: Adjust the laser head 1.4 to a suitable position through the moving device of the working platfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com