Low-carbon clinker doped with scattered metal oxygen-enriched smelting slag, road cement and preparation method of low-carbon clinker

A technology of scattered metals and road cement, which is applied in the field of low-carbon road cement, can solve the problems of low overall utilization rate, comprehensive utilization rate of copper tailings resources less than 20%, and occupying sites, so as to reduce serious burden and treatment costs, and achieve good results. Composite gelation effect, the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

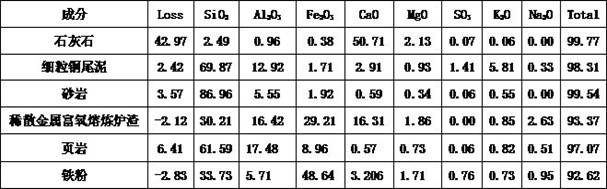

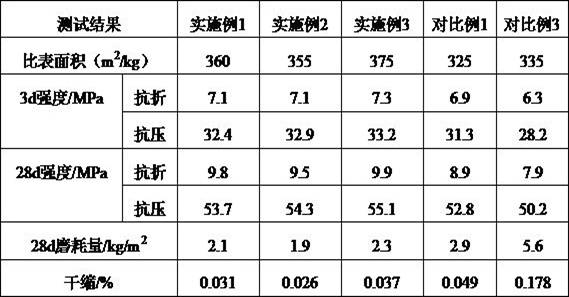

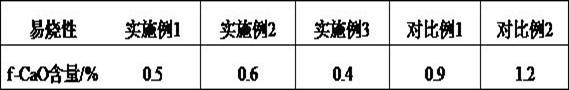

[0054] After the raw materials are dried, 78.5 parts of limestone, 7.1 parts of fine-grained copper tailing mud, 2.8 parts of sandstone, and 11.6 parts of scattered metal oxygen-rich smelting slag are mixed by mass, KH, SM and IM are 0.96, 1.75 and 0.90 respectively, and the powder is ground. After sifting, sifting, homogenizing and making embryonic cake, it is added to the electric furnace for calcination, the calcination temperature is 1380 ℃, the temperature is kept for 30 minutes, and it is taken out and cooled in the atmosphere to obtain road cement clinker.

[0055] According to the mass, 60 parts of cement clinker, 13 parts of scattered metal oxygen-rich smelting slag, 15 parts of lithium slag, 9 parts of water slag, 3 parts of chemical activator, and 0.1 part of compound grinding aid were taken and ground for 30 minutes to obtain a low-carbon road. cement.

[0056] Among the chemical activators, the mass ratio of sodium silicate to aluminum sulfate is 60:40.

[0057] ...

Embodiment 2

[0059] After the raw materials are dried, 78.1 parts of limestone, 5.1 parts of fine-grained copper tailings, 3.8 parts of sandstone, and 13.0 parts of scattered metal oxygen-rich smelting slag are mixed according to mass, KH, SM and IM are 0.97, 1.64 and 0.82 respectively, and the powder is ground. After sifting, sifting, homogenizing and making embryonic cake, it is added to the electric furnace for calcination, the calcination temperature is 1380 ℃, the temperature is kept for 45 minutes, and it is taken out and cooled in the atmosphere to obtain road cement clinker.

[0060] Take 55 parts of cement clinker, 10 parts of scattered metal oxygen-enriched smelting slag, 11 parts of lithium slag, 20 parts of water slag, 4 parts of chemical activator, and 0.1 part of compound grinding aid, and grind for 30 minutes to obtain a low-carbon road. cement.

[0061] Among the chemical activators, the mass ratio of sodium silicate to aluminum sulfate is 30:70.

[0062] Among the composi...

Embodiment 3

[0064] After the raw materials are dried, 78.9 parts of limestone, 7.2 parts of fine-grained copper tailings, 3.9 parts of sandstone, and 10.0 parts of scattered metal oxygen-enriched smelting slag are mixed by mass, KH, SM and IM are 0.93, 1.98 and 0.98 respectively, and the powder is ground. After sifting, sifting, homogenizing and making embryonic cake, it is added to the electric furnace for calcination, the calcination temperature is 1360 ℃, the temperature is kept for 45 minutes, and it is taken out and cooled in the atmosphere to obtain road cement clinker.

[0065] According to the mass, 63 parts of cement clinker, 6 parts of scattered metal oxygen-rich smelting slag, 15 parts of lithium slag, 10 parts of water slag, 4 parts of chemical activator and 0.1 part of compound grinding aid were taken and ground for 30 minutes to obtain a low-carbon road. cement.

[0066]Among the chemical activators, the mass ratio of sodium silicate to aluminum sulfate is 50:50.

[0067] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com