Preparation method for synthesizing magnetic polymer microspheres through chemical copolymerization

A technology of polymer microspheres and copolymerization, which is applied in the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, and microcapsule preparations. The diameter is controllable, easy to control, and the effect of atomization impact is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

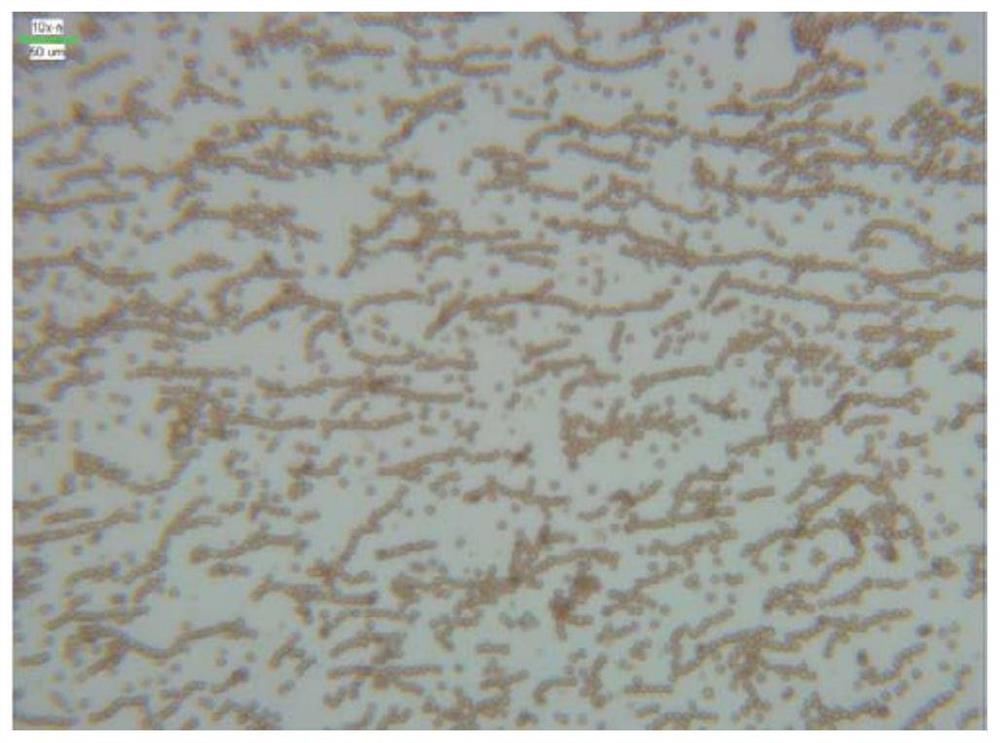

Image

Examples

Embodiment 1

[0035] A method for preparing magnetic polymer microspheres by chemical copolymerization, comprising the following steps:

[0036] (1) Preparation of magnetic fluid:

[0037] The ferric chloride is added to ethylene glycol to prepare a solution of 0.01mol / L; then ferrous chloride is added, and the molar ratio of the ferrous chloride to the ferric chloride is 0.1:2, and the mixture is uniformly stirred and then transferred. In a hydrothermal reactor, react at 200°C for 22 hours; after the reaction, cool to room temperature, centrifuge, wash and dry to obtain a ferrofluid containing hydroxyl groups on the surface;

[0038] (2) Post-modification of olefinic magnetic fluid:

[0039] Add the ferrofluid obtained in step (1) into toluene, stir until the ferrofluid is evenly dispersed, add 3-methacryloyloxypropyltrimethoxysilane, and react under reflux for 24h; the reaction ends After centrifugation, washing and drying, the alkene-modified triferrous tetroxide magnetic fluid can be ...

Embodiment 2

[0047] A preparation method of chemical copolymerization into magnetic polymer microspheres:

[0048] (1) Preparation of magnetic fluid:

[0049] The ferric nitrate was added to the ethylene glycol to prepare a solution of 0.10 mol / L; then ferrous nitrate was added, and the molar ratio of the ferrous nitrate to the ferric nitrate was 0.05:2, and after stirring and mixing, it was transferred to the hydrothermal reaction In the kettle, react at 220°C for 24h; after the reaction, cool to room temperature, centrifuge, wash and dry to obtain the ferrofluid containing hydroxyl groups on the surface;

[0050] (2) Post-modification of olefinic magnetic fluid:

[0051] Add the ferrofluid obtained in step (1) into toluene, stir until the ferrofluid is evenly dispersed, add 3-methacryloyloxypropyltriethoxysilane, and react under reflux for 24h; After the completion of centrifugal separation, washing and drying, the olefinic modified triferrous tetroxide magnetic fluid can be obtained; ...

Embodiment 3

[0058] A preparation method of chemical copolymerization into magnetic polymer microspheres:

[0059] (1) Preparation of magnetic fluid:

[0060] The ferric nitrate was added to the ethylene glycol to prepare a solution of 0.35mol / L; then ferrous nitrate was added, and the molar ratio of the ferrous nitrate to the ferric nitrate was 0.5:2, and the mixture was uniformly stirred and then transferred to the hydrothermal reaction. In the kettle, react at 250°C for 18h; after the reaction, cool to room temperature, centrifuge, wash, and dry to obtain the ferrofluid containing hydroxyl groups on the surface;

[0061] (2) Post-modification of olefinic magnetic fluid:

[0062] Add the triferrous tetroxide magnetic fluid obtained in step (1) into toluene, stir until the triferrous tetroxide magnetic fluid is uniformly dispersed, add 3-methacryloyloxypropylmethyldiethoxysilane, and react under reflux for 24h ; After the reaction, centrifugal separation, washing and drying can be obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com