Method for improving surface biological activity and osseointegration performance of polyether-ether-ketone base material

A polyetheretherketone and substrate surface technology, applied in the field of materials, can solve problems such as inability to mineralize, and achieve the effect of improving biocompatibility and good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The embodiments of the present invention provide a method for improving the surface bioactivity and osseointegration performance of PEEK substrates.

[0042] Tris(2-carboxyethyl) phosphine solution with a concentration of 50mmol / L, after adjusting the pH value to 4-6 with NaOH, and bovine serum albumin solution with a concentration of 2mg / mL in a ratio of 1:10 to 10:1 Mix to make a mixed solution. It should be noted that the concentration of tris(2-carboxyethyl)phosphine in the tris(2-carboxyethyl)phosphine solution can be any concentration in the range of 0.05-600 mM, and the concentration of bovine serum albumin in the bovine serum albumin solution can be Any concentration in the range of 0.05-500 mg / mL, the higher the concentration of each reactant, the thicker the resulting two-dimensional protein nanofilm, and the too low protein concentration will make the resulting two-dimensional protein nanofilm less dense.

[0043] A PEEK substrate with a size of 1 cm × 1 cm ...

Embodiment 2

[0047] The invention provides a method for improving the surface biological activity and osseointegration performance of PEEK substrate.

[0048]The steps in this example are basically the same as those in Example 1, except that the mixture used in the preparation of the PEEK substrate modified by the protein two-dimensional nanofilm is 2 mg / mL lysozyme and 7 mg / mL cysteine in a ratio of 1: It is mixed in a ratio of 10-10:1, and the standing time is 1h.

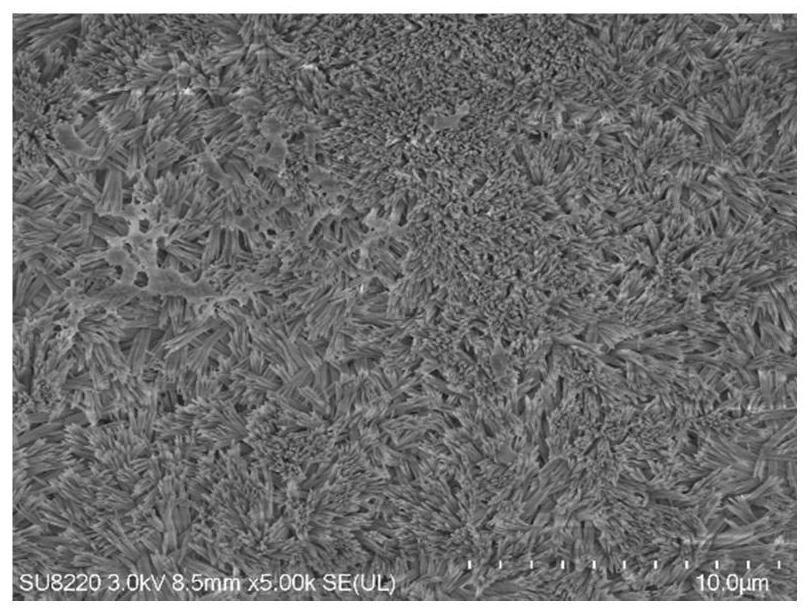

[0049] The hydroxyapatite coating on the surface of the PEEK substrate prepared in this example is as follows after being characterized by SEM. figure 1 shown.

Embodiment 3

[0051] The invention provides a method for improving the surface biological activity and osseointegration performance of PEEK substrate.

[0052] The steps in this example are basically the same as those in Example 1, except that the mixture used in the preparation of the PEEK substrate modified by the protein two-dimensional nanofilm is 2 mg / mL lysozyme and 50 mM TCEP at a ratio of 1:10 to 10:1 The ratio is mixed, and the standing time is 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com