Method and device for measuring geometrical characteristics of inner cavity of solid rocket engine

A technology of solid rockets and geometric features, applied in measuring devices, optical devices, image analysis, etc., can solve high-precision measurement capabilities and economic costs, low cost-effectiveness ratio, limited technical applicability, and hidden dangers of electric excitation sources To achieve the effect of reducing technical difficulty and complexity, integration and application complexity, and moderate measurement environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The embodiment of the present disclosure discloses a method for measuring the geometric characteristics of the inner cavity of a solid rocket motor, comprising the following steps:

[0051] Step 1. Set structured light projection parameters; including:

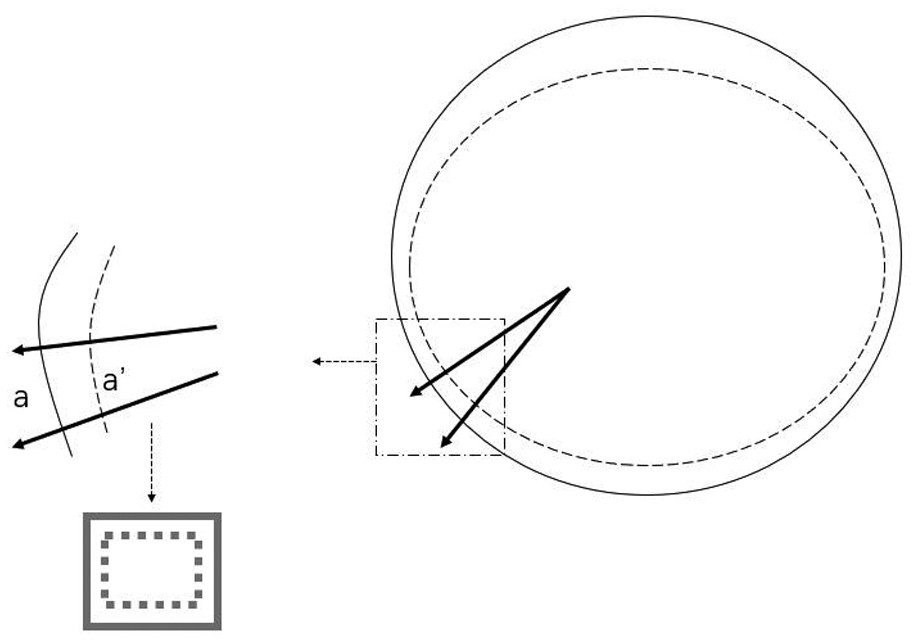

[0052] (1) For a scene with a measurement range of L×D and an objective lens distance of H, define a square grid code as: grid line width d, inner side length a; where L is the axial length; D is the ring to expand the width;

[0053] (2) For the grid numbered i, the deformation of the covering part is processed along the radial direction of the solid rocket motor, so that the distance of the objective lens after deformation becomes H', then the grid parameters become:

[0054] d’=(d×H’) / H, a’=(a×H’) / H (1)

[0055] Define the deformation measurement limit ▽=Hm-H, the corresponding line width dm=(d×Hm) / H; the upper limit of the line width is dm1, and the lower limit of the line width is dm2; where d' is the grid line wid...

Embodiment 2

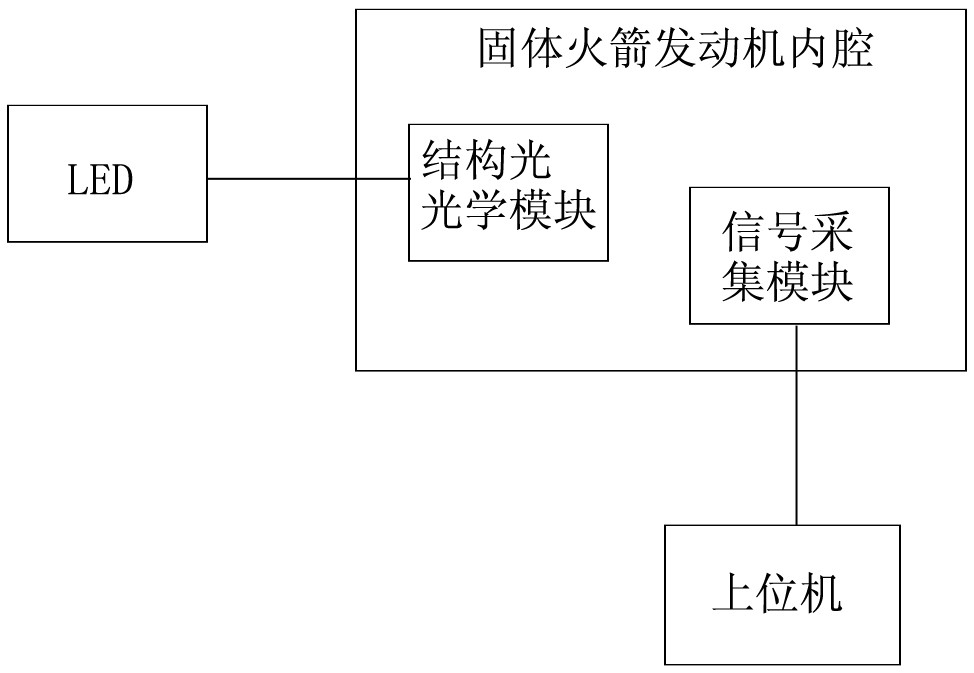

[0068] The embodiment of the present disclosure discloses a device for measuring the geometric characteristics of the inner cavity of a solid rocket motor, such as figure 2 As shown, including LED lighting source, structured light optical module, signal acquisition module and host computer;

[0069] The structured light optical module and the signal acquisition module are both arranged in the inner cavity of the solid rocket motor;

[0070] The LED lighting source is connected with the structured light optical module through a light guide pipe;

[0071] The signal acquisition module is connected with the host computer; in the embodiment of the present disclosure, the signal acquisition module adopts a high-definition endoscopic imaging lens with a model of NTS300 and a pixel of 1 million.

[0072] The structured light optical module described in the embodiments of the present disclosure is used to perform the following steps:

[0073] Step 1. Set structured light projection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com