Lithium ion battery positive electrode slurry, positive electrode plate and lithium ion battery

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., to achieve the effects of enhanced cycle stability, high utilization rate, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a positive electrode slurry for a lithium ion battery, and the specific preparation method is as follows.

[0039] (1) First prepare the carbon-iodine complex:

[0040] Disperse the activated carbon in deionized water, add iodine, then add NaOH solution to make the solution alkaline, stir at room temperature for 3 days, then add hydrochloric acid to make the solution pH 2, wash with water until the solution is neutral, and dry to obtain the carbon Iodine complex. The content of iodine in the carbon-iodine complex is 80 wt.%.

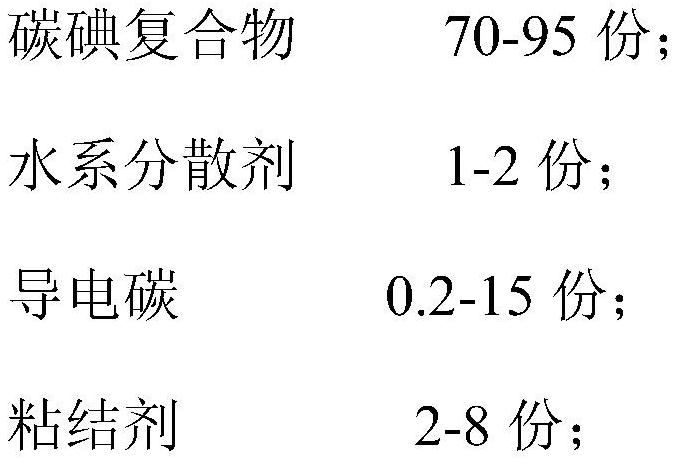

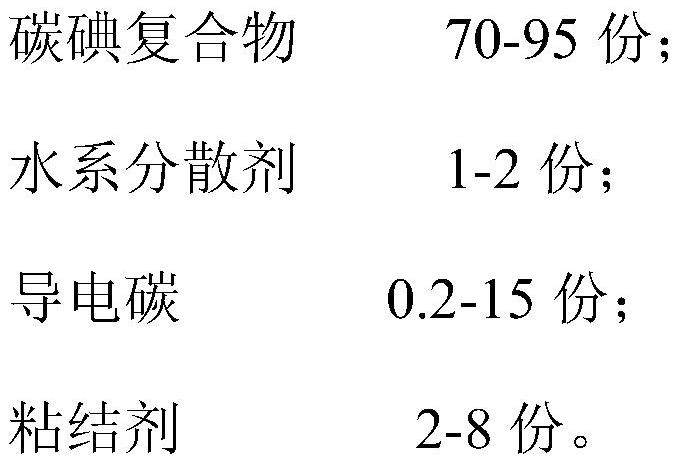

[0041] (2) Then prepare the positive electrode slurry of lithium ion battery:

[0042] Take 90g of carbon-iodine complex, 2g of Ketjen Black, 2g of dispersant CMC, add deionized water and stir at 2500rpm for 2 hours, then add 15g of binder SBR emulsion (SBR content is 40wt.%), stir at 300rpm for 30 minutes to obtain In the positive electrode slurry, the solid content of the slurry is 30 wt.%.

[0043] This embodiment a...

Embodiment 2

[0051] This embodiment provides a lithium-ion battery cathode slurry, and the specific preparation method is as follows:

[0052] (1) First prepare the carbon-iodine complex:

[0053] Disperse the activated carbon in deionized water, add iodine, then add NaOH solution to make the solution alkaline, stir at room temperature for 3 days, then add hydrochloric acid to make the solution pH 2, wash with water until the solution is neutral, and dry to obtain the carbon Iodine complex. The content of iodine in the carbon-iodine complex is 80 wt.%.

[0054] (2) Then prepare the positive electrode slurry of lithium ion battery:

[0055] Take 92g of carbon-iodine complex, 2g of Ketjen Black, 1g of dispersant CMC, add deionized water and stir at 2000rpm for 2 hours, then add 25g of acrylate copolymer aqueous solution (acrylate copolymer content 20wt.%), at 2000rpm The positive electrode slurry was obtained by stirring for 2 hours, and the solid content of the slurry was 35 wt.%.

[00...

Embodiment 3

[0064] This embodiment provides a lithium-ion battery cathode slurry, and the specific preparation method is as follows:

[0065] (1) First prepare the carbon-iodine complex:

[0066] Disperse the activated carbon in deionized water, add iodine, then add NaOH solution to make the solution alkaline, stir at room temperature for 3 days, then add hydrochloric acid to make the solution pH 2, wash with water until the solution is neutral, and dry to obtain the carbon Iodine complex. The content of iodine in the carbon-iodine complex is 80 wt.%.

[0067] (2) Then prepare the positive electrode slurry of lithium ion battery:

[0068] Take 92g of carbon-iodine complex, 1g of Ketjen black, 2g of polyacrylamide, add deionized water and stir at 3000rpm for 3 hours, then add 12.5g of binder SBR emulsion (SBR content 40wt.%), stir at 200rpm for 30 minutes to obtain In the positive electrode slurry, the solid content of the slurry is 35 wt.%.

[0069] This embodiment also provides a lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com