Lithium metal battery charging and discharging method

A lithium metal battery, charging and discharging technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the safety problems of lithium metal negative electrodes such as broken sand, lithium metal battery capacity and coulombic efficiency decay , battery coulombic efficiency reduction and other issues, to achieve good results, prevent decomposition, reduce internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

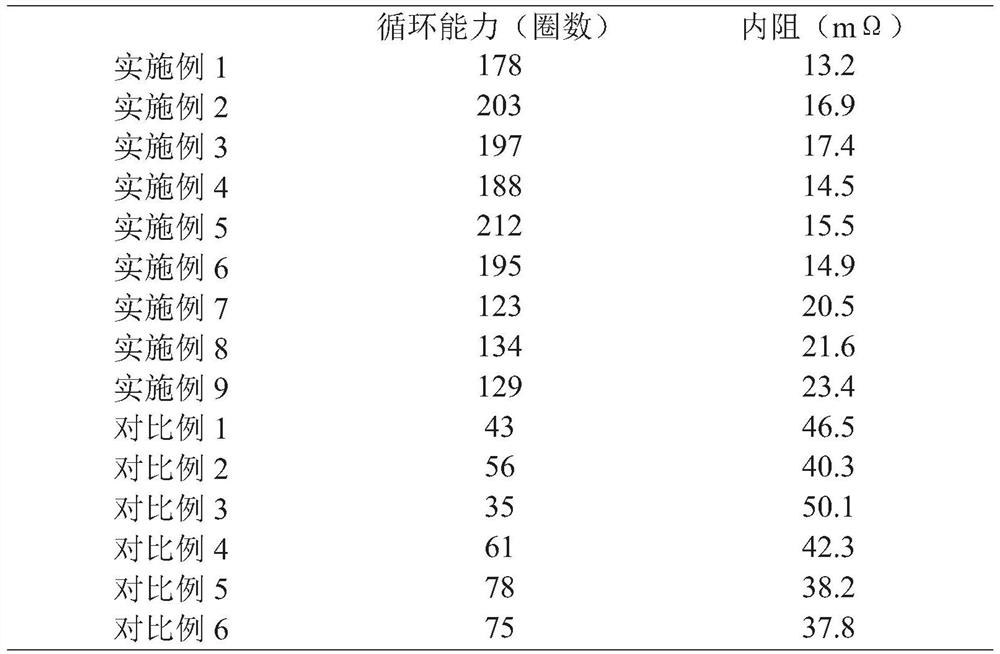

Examples

preparation example Construction

[0043] 1) Preparation of positive electrode sheet: under low dew point conditions (-40 °C), LiNi was prepared in NMP solvent. 0.8 Co 0.1 Mn 0.1 O 2 Mix evenly with conductive agent (SP) and adhesive (PVDF) in a weight ratio of 97:1.5:1.5, and stir at high speed in a vacuum to make a positive electrode slurry; evenly coat the slurry on 10 μm aluminum foil to prepare a positive electrode slurry. The pole piece is dried in a vacuum environment of 85 ℃, and is cut into pieces by rolling to obtain a positive pole piece;

[0044] 2) preparation of negative electrode sheet: in the glove box full of argon, the lithium band is punched into a standard shape with a die-cutting machine, and its surface is polished and polished, and then rolled and flattened to obtain a negative electrode sheet;

[0045]3) Preparation of the battery cell: The prepared positive electrode sheet, the negative electrode sheet and the polyethylene separator with a thickness of 19 μm are laminated in turn to ...

Embodiment 1

[0047] 1) Heat the lithium metal battery to 40°C and let it stand for 40 minutes;

[0048] 2) Constant current discharge is performed on the lithium metal battery with a current of 0.09C until the voltage reaches 3.0V;

[0049] 3) Continue to discharge the lithium metal battery at a constant current with a current of 0.02C until the voltage reaches 2.9V;

[0050] 4) Between 2.9V and 3.0V, charge and discharge the lithium metal battery 3 times with a constant current of 0.02C;

[0051] 5) Charge the lithium metal battery with constant current and constant voltage at a current of 0.1C until the voltage reaches 4.3V;

[0052] 6) Between 4.3V and 4.4V, the lithium metal battery is subjected to pulse charge and discharge cycles for 3 times, the pulse action time is 10s, the interval time is 1s, and the pulse current is 0.05C;

[0053] 7) Between 3.0V and 4.3V, charge and discharge the lithium metal battery 3 times with a constant current of 0.1C;

[0054] 8) Let the battery cool...

Embodiment 2

[0056] 1) Heat the lithium metal battery to 45°C and let it stand for 40 minutes;

[0057] 2) Constant current discharge of the lithium metal battery with a current of 0.08C until the voltage reaches 2.95V;

[0058] 3) Continue to discharge the lithium metal battery at a constant current with a current of 0.01C until the voltage reaches 2.85V;

[0059] 4) Between 2.85V and 2.95V, charge and discharge the lithium metal battery 3 times with a constant current of 0.01C;

[0060] 5) Charge the lithium metal battery with a constant current and constant voltage at a current of 0.2C until the voltage reaches 4.25V;

[0061] 6) Between 4.25V and 4.35V, the lithium metal battery is subjected to pulse charge and discharge cycles for 3 times, the pulse action time is 10s, the interval time is 1s, and the pulse current is 0.04C;

[0062] 7) Between 2.95V and 4.25V, charge and discharge the lithium metal battery 3 times with a constant current of 0.2C;

[0063] 8) Let the battery cool d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com