Tungstate ionic liquid, preparation method thereof and application of tungstate ionic liquid in catalytic oxidation degradation of phenol and derivatives thereof in wastewater

A technology of tungstate ion and oxidative degradation, which is applied in the fields of oxidized water/sewage treatment, water pollutants, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation of tungstate ionic liquid and a method for catalyzing and oxidatively degrading phenol, comprising the following steps:

[0044] 1) Silver tungstate was prepared by mixing sodium tungstate with silver nitrate aqueous solution at room temperature, washed and dried under vacuum at 80°C for 4h.

[0045] 2) The sodium tungstate and silver nitrate in step 1) are mixed according to the molar ratio of 1:1.

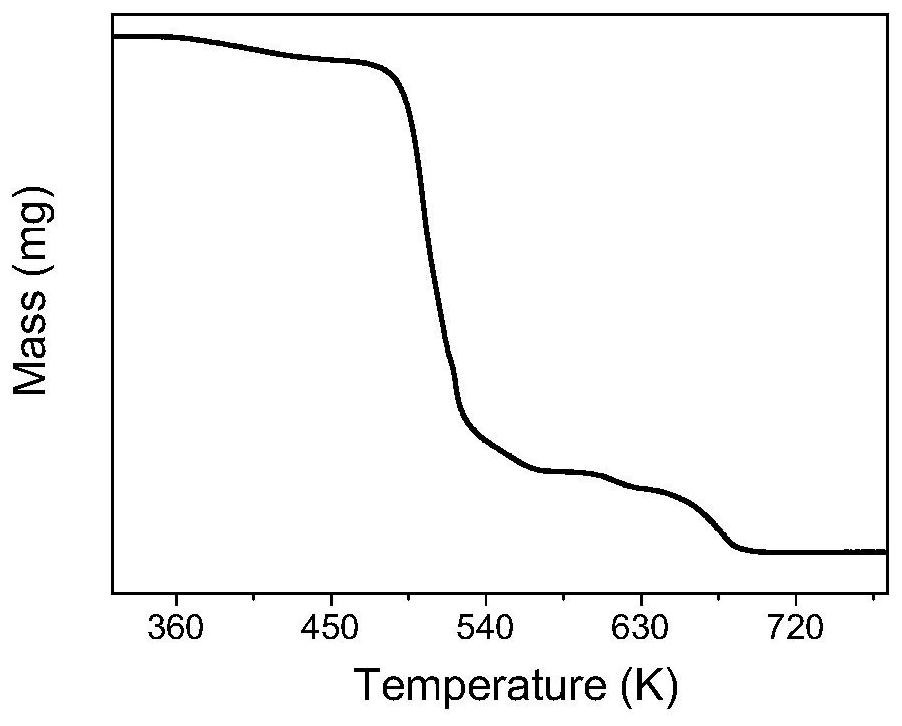

[0046] 3) The silver tungstate prepared in step 1) and the aqueous solution of dodecyl trimethyl quaternary ammonium bromide are mixed according to the molar ratio of silver tungstate and dodecyl trimethyl quaternary ammonium bromide 1:2, and stirred for 2h , filtered, washed three times with ether after concentration, and finally rotary-evaporated and vacuum-dried at 80 °C overnight to obtain tungstate ionic liquid. Its thermogravimetric analysis results are as follows figure 1 shown.

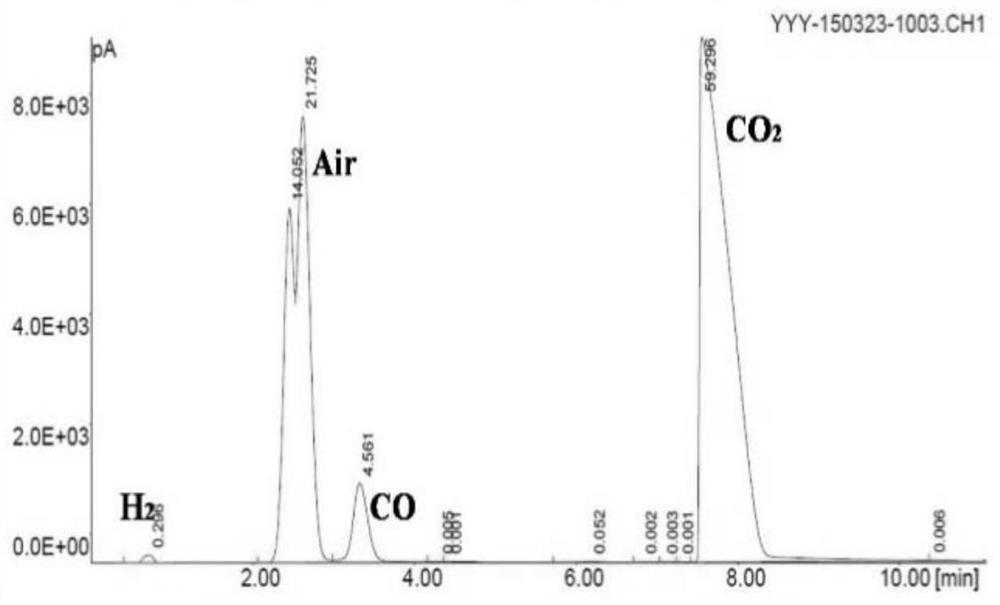

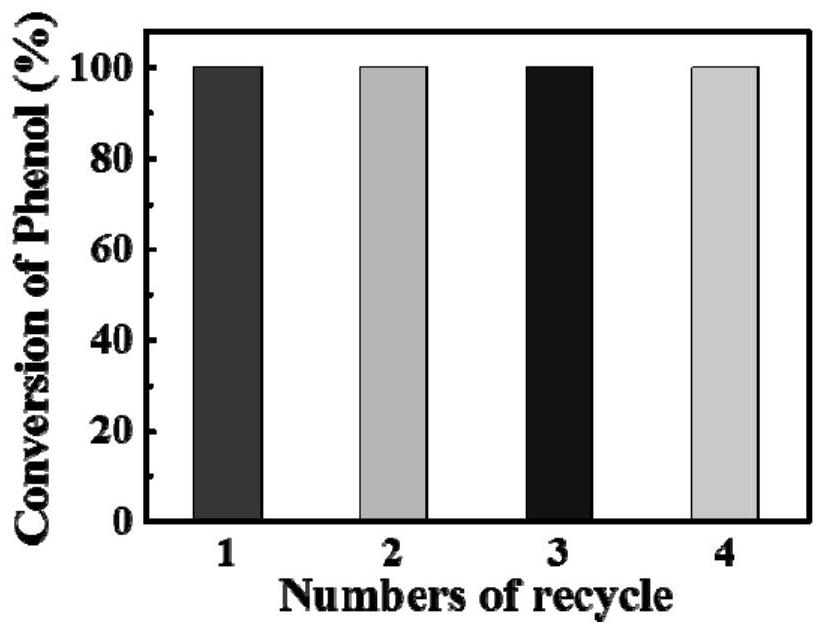

[0047] 4) Choose 50g L -1 The phenol aqueous solution is used as a r...

Embodiment 2

[0050] A preparation of tungstate ionic liquid and a method for catalytic oxidation degradation of nitrophenol, comprising the following steps:

[0051] 1) The silver tungstate was prepared by mixing sodium tungstate with silver nitrate aqueous solution at room temperature, and after washing, it was vacuum-dried at 90 °C for 4 h.

[0052] 2) The sodium tungstate and silver nitrate in step 1) are mixed according to the molar ratio of 1:2.

[0053] 3) The silver tungstate prepared in step 1) and the aqueous solution of decyltrimethylimidazolium chloride are mixed according to the molar ratio of silver tungstate and decyltrimethylimidazolium chloride 1:2, stirred for 4h, filtered and concentrated After washing three times with ether, finally rotary evaporation and vacuum drying at 100 °C overnight to obtain tungstate ionic liquid.

[0054] 4) Choose 20g L -1 The nitrophenol aqueous solution is used as reactant, the molar ratio of decyl trimethyl quaternary imidazole tungstate a...

Embodiment 3

[0057] A preparation of tungstate ionic liquid and a method for catalytic oxidation degradation of trichlorophenol, comprising the following steps:

[0058] 1) The silver tungstate was prepared by mixing sodium tungstate with silver nitrate aqueous solution at room temperature, washed and dried under vacuum at 60°C for 4h.

[0059] 2) The sodium tungstate and silver nitrate in step 1) are mixed according to the molar ratio of 1:1.

[0060] 3) The silver tungstate prepared in step 1) and the aqueous solution of hexadecyltrimethyl quaternary phosphonium chloride are mixed according to the molar ratio of silver tungstate and hexadecyltrimethyl quaternary phosphonium chloride 1:2, and stirred for 6h , filtered, washed three times with ether after concentration, and finally rotary-evaporated and vacuum-dried at 110 °C overnight to obtain tungstate ionic liquid.

[0061] 4) Choose 80g L -1 The trichlorophenol aqueous solution is used as reactant, the molar ratio of hexadecyltrimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com