Impression material as well as preparation method and application thereof

An impression material and raw material technology, applied in the field of impression material and its preparation, can solve the problems of inability to effectively meet the performance requirements of the female mold, high irritation of human skin, poor tear resistance, etc., and achieve low price and easy acquisition , to avoid irritating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

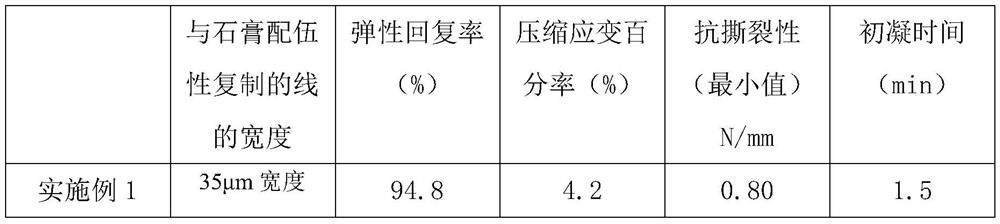

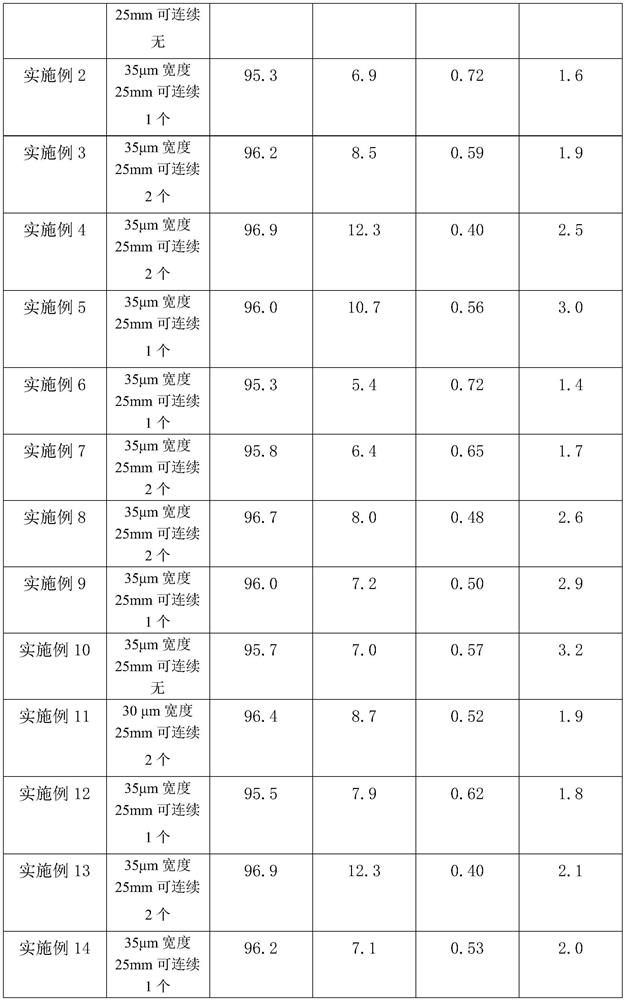

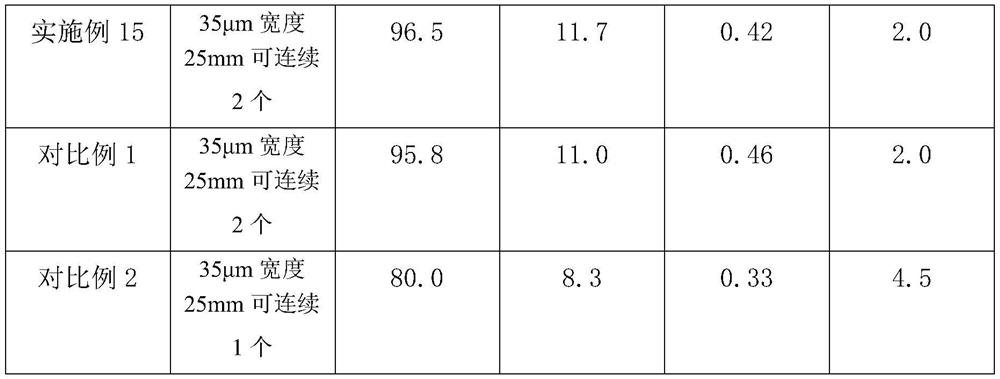

Examples

Embodiment 1

[0030] This embodiment provides an impression material, which includes the following raw materials: rice bran (granular, with an average particle size of 40 microns) 40g, sodium alginate 17.8g, sodium pyrophosphate 4.2g, gypsum 22.9g, zinc oxide 2.8 g, 2.5 g of potassium fluorotitanate, 1.1 g of sodium carbonate, and 8.7 g of polyethylene glycol 4000.

[0031] The preparation method of the above-mentioned impression material comprises the following steps: placing the above-mentioned rice bran, sodium alginate, sodium pyrophosphate, gypsum, zinc oxide, potassium fluorotitanate, sodium carbonate, and polyethylene glycol in a high-speed mixer to mix, The rotating speed of 180 r / min was stirred for 20 min to uniformly mix the above-mentioned raw materials to obtain the impression material.

Embodiment 2

[0033] This embodiment provides an impression material, which includes the following raw materials: rice bran 50g (granular, with an average particle size of 45 microns), sodium alginate 14.8g, sodium pyrophosphate 3.5g, gypsum 19.1g, zinc oxide 2.3 g, 2.1 g of potassium fluorotitanate, 0.9 g of sodium carbonate, and 7.3 g of polyethylene glycol 4000.

[0034] The preparation method of the above-mentioned impression material comprises the following steps: placing the above-mentioned rice bran, sodium alginate, sodium pyrophosphate, gypsum, zinc oxide, potassium fluorotitanate, sodium carbonate, and polyethylene glycol in a high-speed mixer to mix, The rotating speed of 100r / min was stirred for 50min, so that the above-mentioned raw materials were evenly mixed to obtain the impression material.

Embodiment 3

[0036] This embodiment provides an impression material, which includes the following raw materials: rice bran 60g (granular, with an average particle size of 30 microns), sodium alginate 11.9g, sodium pyrophosphate 2.8g, gypsum 15.3g, zinc oxide 1.9 g, 1.6 g of potassium fluorotitanate, 0.7 g of sodium carbonate, and 5.3 g of polyethylene glycol 4000.

[0037]The preparation method of the above-mentioned impression material comprises the following steps: placing the above-mentioned rice bran, sodium alginate, sodium pyrophosphate, gypsum, zinc oxide, potassium fluorotitanate, sodium carbonate, and polyethylene glycol in a high-speed mixer to mix, The rotation speed of 200 r / min was stirred for 20 minutes to mix the above raw materials uniformly to obtain the impression material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com