Preparation method and application of dust suppressant with photocatalytic degradation function

A technology of dust suppressant and photocatalysis, which is applied in the field of preparation of dust suppressant to achieve the effects of suppressing dispersion, good trapping and sedimentation effect, and good water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

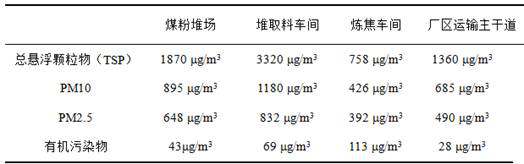

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 60kg of sodium alginate to the reactor filled with 200L of water, stir until the sodium alginate is completely dissolved, adjust the temperature of the reactor to 50°C, slowly add 21kg of glycerol and 15kg of polyvinyl alcohol, stir until completely dissolved and then add 0.6kgN, N-methylenebisacrylamide, maintain the temperature of the reaction kettle at 50°C, and stir at a rate of 150 rpm, introduce nitrogen into the reaction kettle, and react for 2 hours. After the reaction, adjust the pH of the solution to 7 with HCl, and dry the solution to collect the solid product. , wash the product 3 times with absolute ethanol, and dry to constant weight to obtain a dust suppressant matrix material rich in hydrophilic groups and having a network structure, and the collection material is sealed for use;

[0029] In the reactor, add 180L absolute ethanol and 20L water to make ethanol-aqueous solution, then add the nano-TiO of 10kg 2Powder, 1kg of KH-550 silane coupling agent...

Embodiment 2

[0031] Add 50kg of sodium lignosulfonate to the reactor filled with 160L of water, stir until the sodium lignosulfonate is completely dissolved, adjust the temperature of the reactor to 40°C, slowly add 25kg of propylene glycol and 15kg of soluble starch, stir until completely dissolved and then add 0.75kg of N,N-methylenebisacrylamide, maintain the temperature of the reaction kettle at 40°C and the stirring rate at 170rpm, feed nitrogen into the reaction kettle, react for 1h, adjust the pH of the solution to 7 with HCl after the reaction, and dry the solution Collect the solid product, wash the product with absolute ethanol 3 times, and dry to constant weight to obtain a dust suppressant matrix material rich in hydrophilic groups and having a network structure, and the collected material is sealed for use;

[0032] In the reactor, add 144L absolute ethanol and 16L water to make ethanol-aqueous solution, then add the nano-TiO of 10kg 2 Powder, 0.75kg of KH-560 silane coupling ...

Embodiment 3

[0034] Add 40kg of sodium alginate to the reactor filled with 120L of water, stir until the sodium alginate is completely dissolved, adjust the temperature of the reactor to 45°C, slowly add 26kg of butanediol and 14kg of polyvinyl alcohol, stir until completely dissolved and then add 0.8kgN ,N-methylenebisacrylamide, keep the temperature of the reaction kettle at 45°C, the stirring speed is 200rpm, pass nitrogen into the reaction kettle, react for 2h, adjust the pH of the solution to 7.5 with HCl after the reaction, and dry the solution to collect the solid The product was washed 3 times with absolute ethanol, and dried to constant weight to obtain a dust suppressant matrix material rich in hydrophilic groups and having a network structure, and the collected material was sealed for use;

[0035] In the reactor, add 120L absolute ethanol and 12L water to make ethanol-aqueous solution, then add the nano-TiO of 10kg 2 Powder, 0.8kg of KH-570 silane coupling agent and 0.14kg of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com