Determination method for related substances in glimepiride bulk drug

A technology of related substances and determination methods, which is applied in the field of determination of related substances in glimepiride raw materials, can solve the problems of inability to fully react, detect a small amount of impurities, and poor specificity, and achieve high separation, high accuracy, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

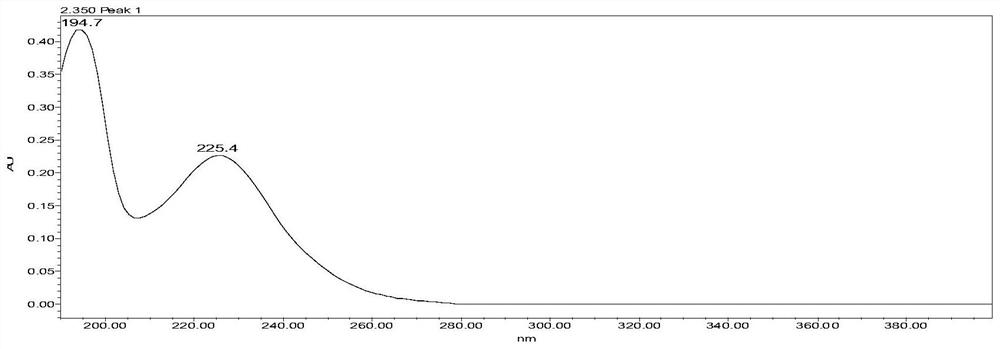

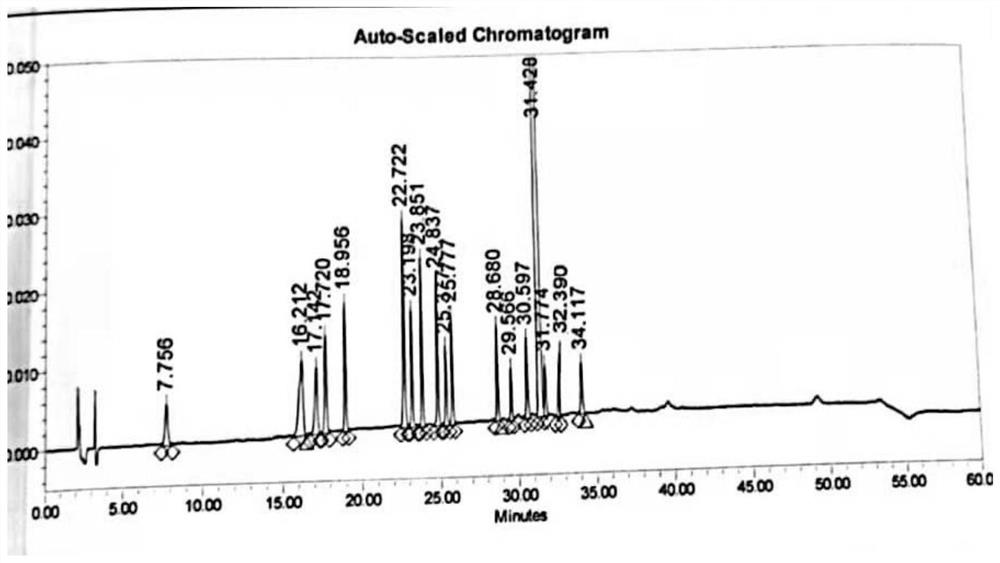

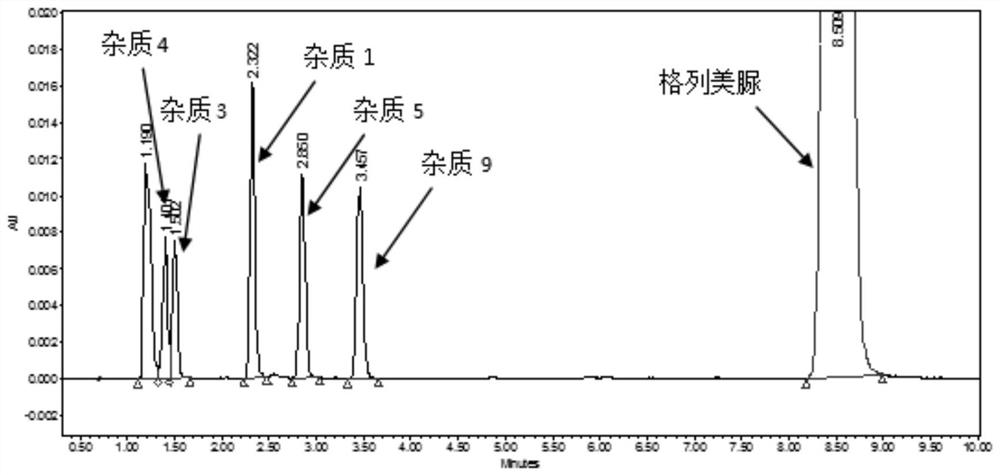

[0024] Example 1: System applicability of the assay method of the present invention

[0025] 1. Solution Preparation

[0026] Diluent: 80% acetonitrile in water

[0027] Test solution: take an appropriate amount of the test, accurately weigh it, add diluent to dissolve and dilute to make a test solution with a concentration of 20 mg / mL.

[0028] Reference solution: Precisely measure 1mL of the test solution, put it in a 100mL volumetric flask, dilute it to the mark with diluent, shake well, and use it as a control solution.

[0029] The preparation of each impurity positioning solution: take the impurity 1, impurity 2, impurity 3, impurity 4, impurity 5, impurity 6, impurity 7, impurity 8, impurity 9, impurity 10, impurity 11, impurity 12, Impurity 13, Impurity 14, Impurity 5, Impurity 16, and Impurity 17 reference substances were added in appropriate amounts, respectively, dissolved in diluent, and diluted to prepare each impurity positioning solution with a concentration o...

Embodiment 2

[0056] Example 2: Examination of the durability of chromatographic conditions - the pH of the mobile phase A is different

[0057] The only difference between Example 2 and Example 1 is that the pH of the mobile phase A used is different (pH 4.0±0.2).

[0058] The specific chromatographic conditions are as follows:

[0059] Mobile phase A: 0.1% sodium dihydrogen phosphate solution (adjust pH to 4.2 or 3.8 with phosphoric acid)

[0060] Other chromatographic conditions are the same as in Example 1.

[0061] Test results:

[0062] According to the above chromatographic conditions, the system suitability solution was injected, and the results showed that the separation degree of each impurity was good, indicating that the pH of the mobile phase A phase was between 3.8 and 4.2, and other conditions remained unchanged. Impurities are effectively separated.

Embodiment 3

[0063] Example 3: Examination of the durability of chromatographic conditions - different column temperatures

[0064] The only difference between Example 3 and Example 1 is that the column temperature is different (30±5°C).

[0065] The specific chromatographic conditions are as follows:

[0066] Column temperature: 25℃ or 35℃

[0067] Other chromatographic conditions are the same as in Example 1.

[0068] Test results:

[0069] According to the above chromatographic conditions, the system suitability solution was injected, and the separation degree of each impurity was good, indicating that the column temperature was between 25 and 35 °C, and other conditions remained unchanged, and the 17 impurities listed in Table 1 in the system suitability solution could be effectively separated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com