Modified high-nickel ternary positive electrode material and preparation method thereof

A cathode material, high nickel technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

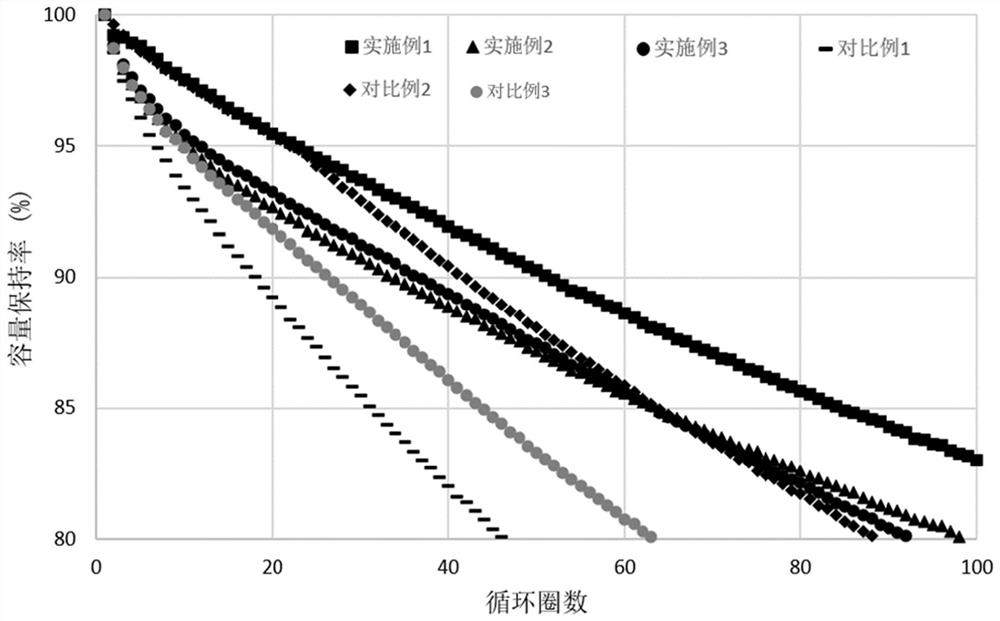

Embodiment 1

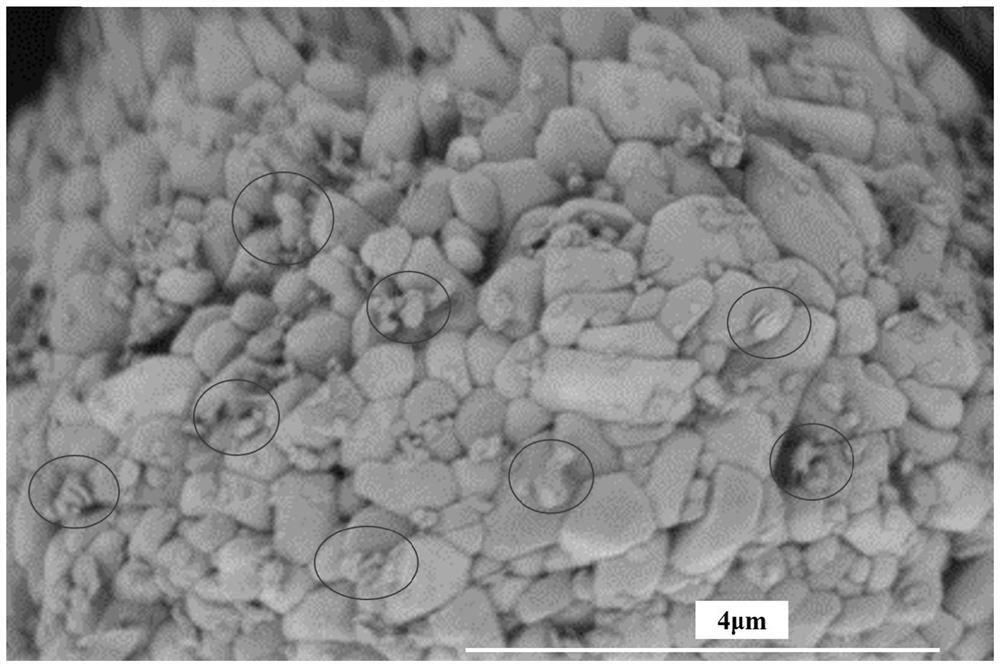

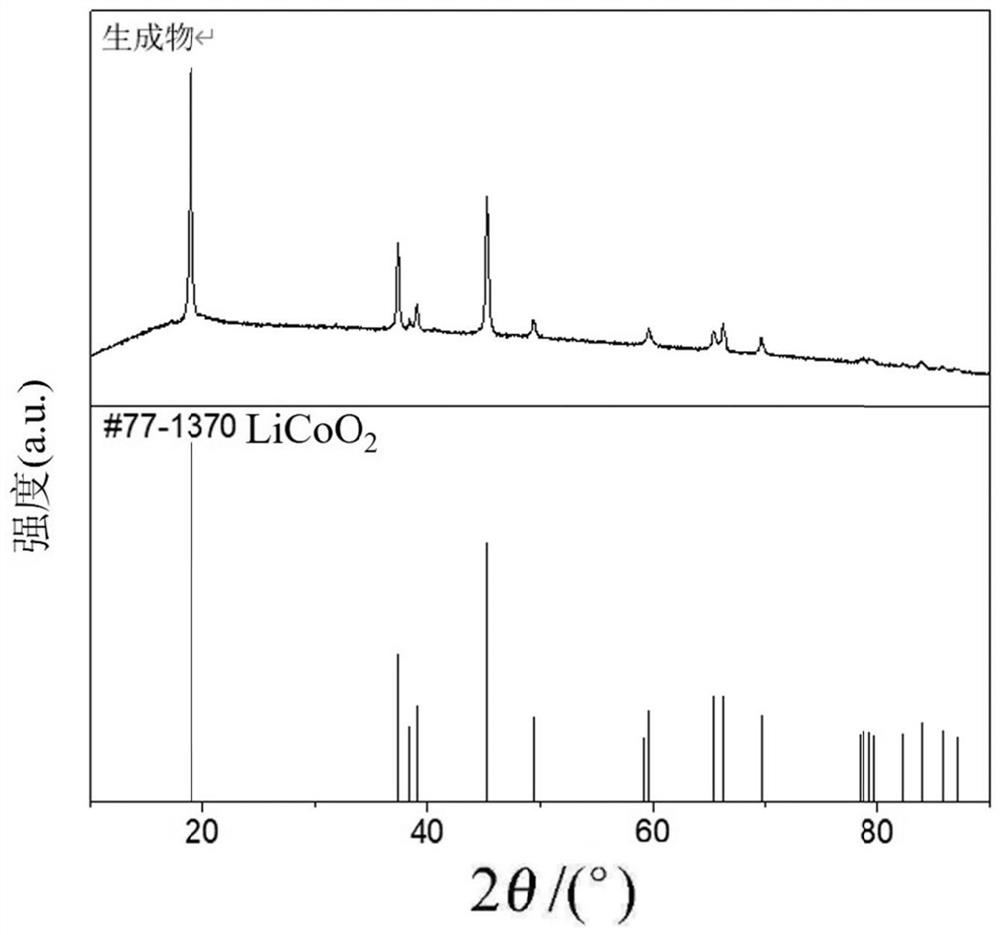

[0054] Example 1 Preparation of a modified high nickel ternary positive electrode material

[0055] (1) Preparation of nickel-cobalt-manganese hydroxide precursor coated with cobalt element on the surface:

[0056] Dissolve 45.82 g of cobalt chloride hexahydrate in 120 mL of deionized water to prepare a cobalt chloride aqueous solution, and place the cobalt chloride aqueous solution in a spray device. Take 1111.7g nickel cobalt manganese hydroxide precursor Ni 0.95 Co 0.03 Mn 0.02 (OH) 2 It is placed in a high-efficiency mixer with heating function for stirring, the heating temperature is 150 °C, and the stirring speed is 600 rpm. In the process of high-speed stirring of the precursor, use the spray equipment equipped with cobalt chloride aqueous solution for spraying, control the spray time to 30min, the spray flow rate to 4mL / min, the solution is completely sprayed, and the high-efficiency mixer with heating function after spraying Continue stirring for 120 min until Ni...

Embodiment 2

[0061] Example 2 Preparation of a modified high nickel ternary positive electrode material

[0062] (1) Preparation of nickel-cobalt-manganese hydroxide precursor coated with cobalt element on the surface:

[0063] Dissolve 34.92 g of cobalt nitrate in 120 mL of deionized water to prepare an aqueous cobalt nitrate solution, and place the aqueous cobalt nitrate solution in a spray device. Take 1111.7g nickel cobalt manganese hydroxide precursor Ni 0.95 Co 0.03 Mn 0.02 (OH) 2 It is placed in a high-efficiency mixer with heating function for stirring, the heating temperature is 150 °C, and the stirring speed is 600 rpm. In the process of high-speed stirring of the precursor, use a spray device equipped with a cobalt nitrate aqueous solution for spraying, control the spray time to 30min, the spray flow rate to 4mL / min, the solution is completely sprayed, and the high-efficiency mixer with heating function continues after spraying. Stir for 120 min until the precursor is fully...

Embodiment 3

[0068] Example 3 Preparation of a modified high nickel ternary positive electrode material

[0069] (1) Preparation of nickel-cobalt-manganese hydroxide precursor coated with cobalt element on the surface:

[0070] Dissolve 84.65 g of cobalt acetate tetrahydrate in 120 mL of deionized water to prepare a cobalt acetate aqueous solution, and place the cobalt acetate aqueous solution in a spray device. Take 1kg nickel cobalt manganese hydroxide precursor Ni 0.95 Co 0.03 Mn 0.02 (OH) 2 It is placed in a high-efficiency mixer with heating function for stirring, the heating temperature is 150 °C, and the stirring speed is 600 rpm. In the process of high-speed stirring of the precursor, use a spray device equipped with a cobalt acetate aqueous solution for spraying, control the spray time to 30min, the spray flow rate to 4mL / min, the solution is completely sprayed, and the high-efficiency mixer with heating function continues after spraying. Stir for 120 min until the precursor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com