Adhesive tape agent

A tape and gel technology, applied in bandages, pharmaceutical formulations, medical science, etc., can solve the problems of adhesive residue, insufficient stimulation suppression, and exudation, and achieve the effect of improving release and inhibiting skin irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

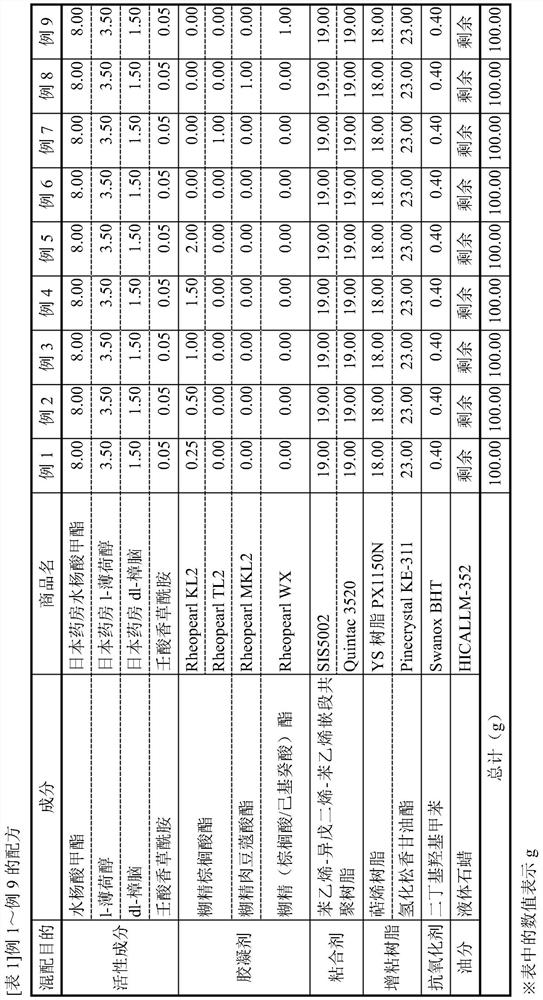

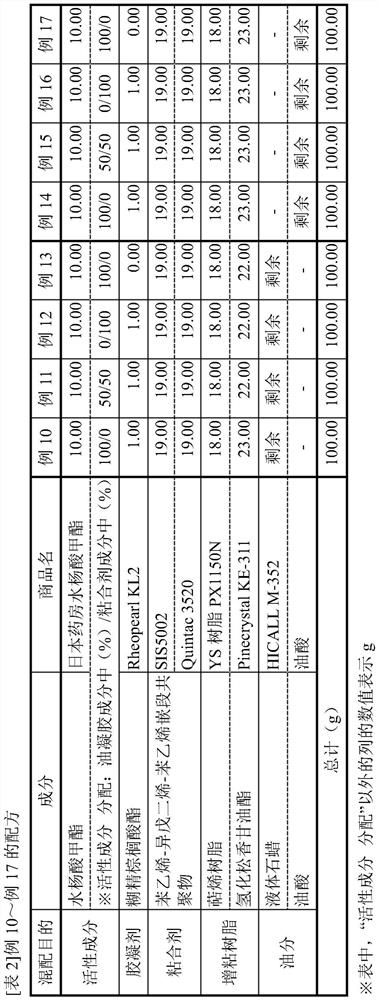

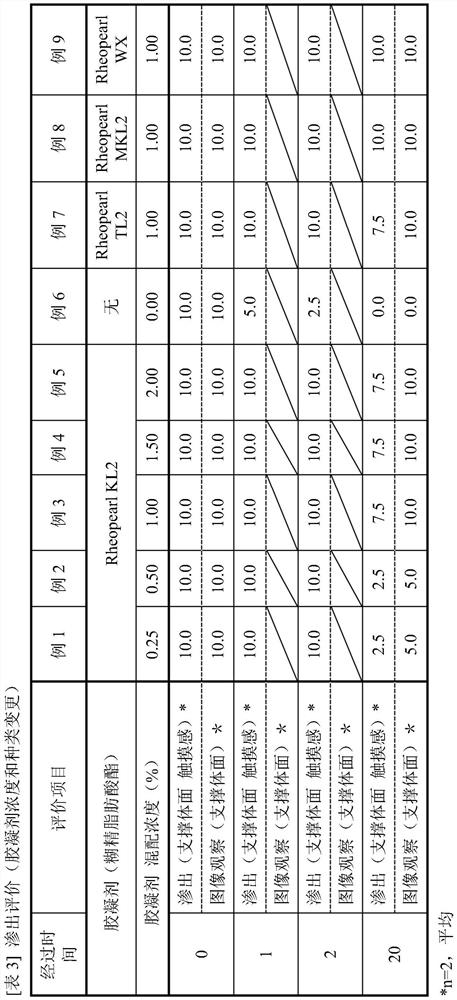

[0134] Although an Example is shown below and this invention is demonstrated concretely, this invention is not limited to these Examples.

[0135] [Manufacture of adhesive tape (1)]

example 1

[0137] Dextrin palmitate (RheopearlKL2, Chiba Milling Co., Ltd.) was dissolved in (80-100°C, 150rpm, 10min) liquid paraffin (HICALLM) in a high-speed rotary mixer according to the compounding amount described in Table 1. -352, Kaneda Co., Ltd.). Moreover, the same operation was performed except that dextrin palmitate was not added about Example 6 which did not mix|blend dextrin fatty acid ester (henceforth a gelling agent), such as dextrin palmitate.

[0138] After the dextrin palmitate is dissolved, add methyl salicylate (Methyl salicylate from Japanese pharmacy), l-menthol (Japanese pharmacy l-menthol), dl-camphor (Japanese pharmacy dl-camphor), nonanoic acid Vanillamide (vanillamide pelargonate), styrene-isoprene-styrene block copolymer (the following SIS) (SIS5002: JSR Co., Ltd. and Quintac 3520: Nippon Zeon Co., Ltd.), terpene resin ( YS resin PX1150N; Yasuhara Chemical Co., Ltd.), hydrogenated rosin glyceride (Pinecrystal KE311: Arakawa Chemical Industry Co., Ltd.), and...

example 2

[0141] Except having changed the compounding quantity of dextrin palmitate into 0.5 mass %, it carried out similarly to Example 1, and obtained the adhesive tape which contained the packaging material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com