Treatment method of electrolytic manganese residues

A treatment method and technology for electrolytic manganese slag, applied in chemical instruments and methods, improvement of process efficiency, removal of solid waste, etc., can solve the problems of complex raw materials, secondary pollution, high cost, reduce ammonia nitrogen content, and reduce raw materials. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 100 parts by weight of electrolytic manganese slag and 10 parts by weight of calcium oxide are uniformly stirred and then placed in a muffle furnace crucible for calcination; then cooled and crushed with the furnace to obtain processed manganese slag.

[0048] The calcination process conditions are as follows: heating up to 300°C at a heating rate of 10°C / min, and calcining at 300°C for 30min; heating up to 600°C at a heating rate of 10°C / min, and calcining at 600°C for 60min; The temperature was raised to 900 °C at a heating rate of min, and calcined at 900 °C for 60 min; the temperature was raised to 1500 °C at a heating rate of 5 °C / min, and calcined at 1500 °C for 180 min.

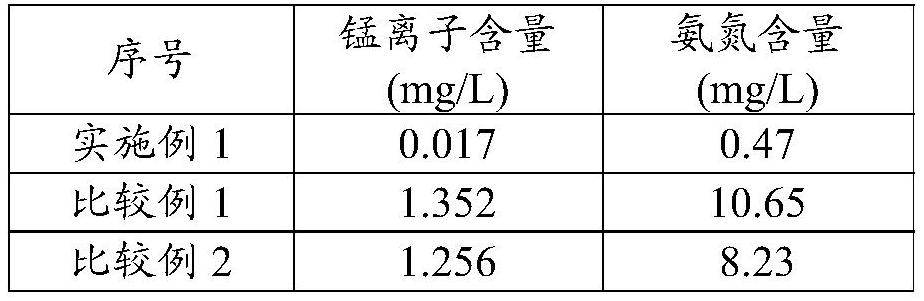

[0049] The manganese ion content and ammonia nitrogen content in the obtained manganese slag after treatment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com