Preparation method of cobalt-vanadium sulfide and application of cobalt-vanadium sulfide as sodium-ion battery negative electrode material

A sodium-ion battery and sulfide technology, applied in the direction of vanadium compounds, cobalt compounds, battery electrodes, etc., can solve the problems of large volume expansion, poor cycle performance, etc., achieve high rate performance, improve cycle life, and controllable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 0.5mmol CoCl 2 ·6H 2 O, 0.5 mmol VCl 3 , 15mmol of urea and 2.5mmol of TAA were added to deionized water, and after magnetic stirring was uniform, the mixed solution was transferred to the substrate of a polytetrafluoroethylene reactor, and further reacted at a high temperature of 120 ° C for 24h, the slurry was filtered through a microporous membrane, Water and ethanol are repeatedly washed to remove impurities, and the final product is dried in an oven overnight, and the solid is ground to obtain the final cobalt vanadium sulfide electrode material.

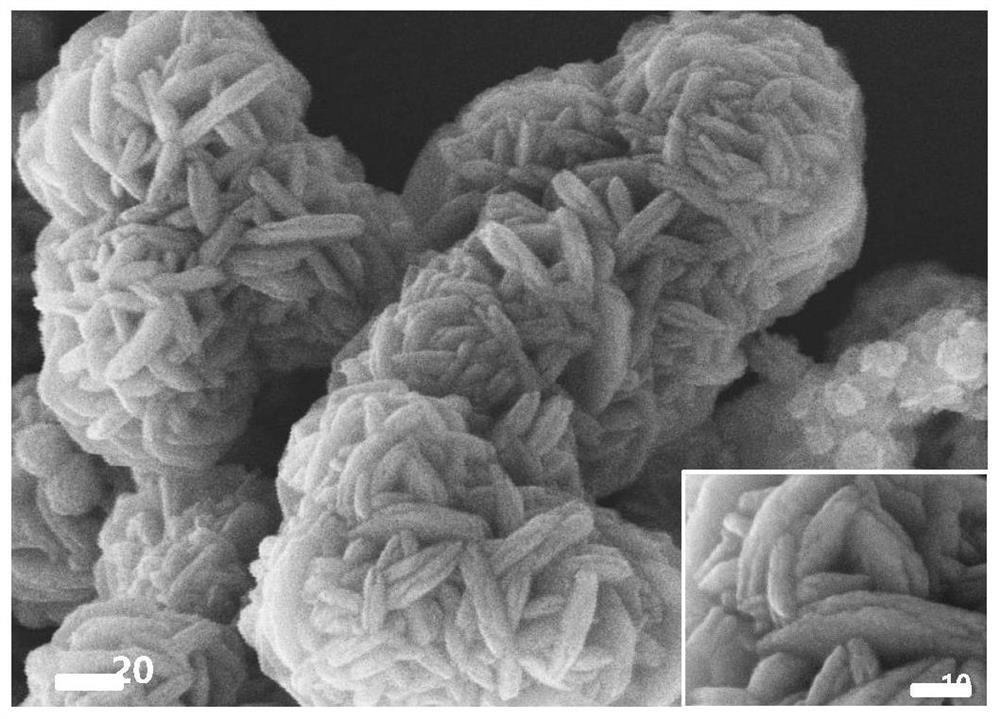

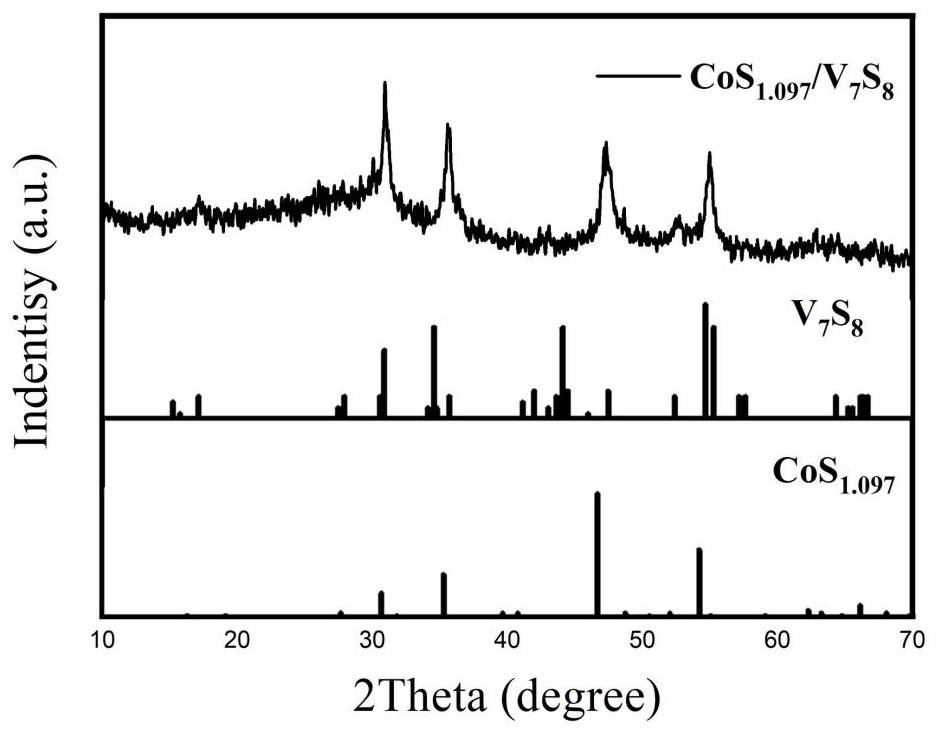

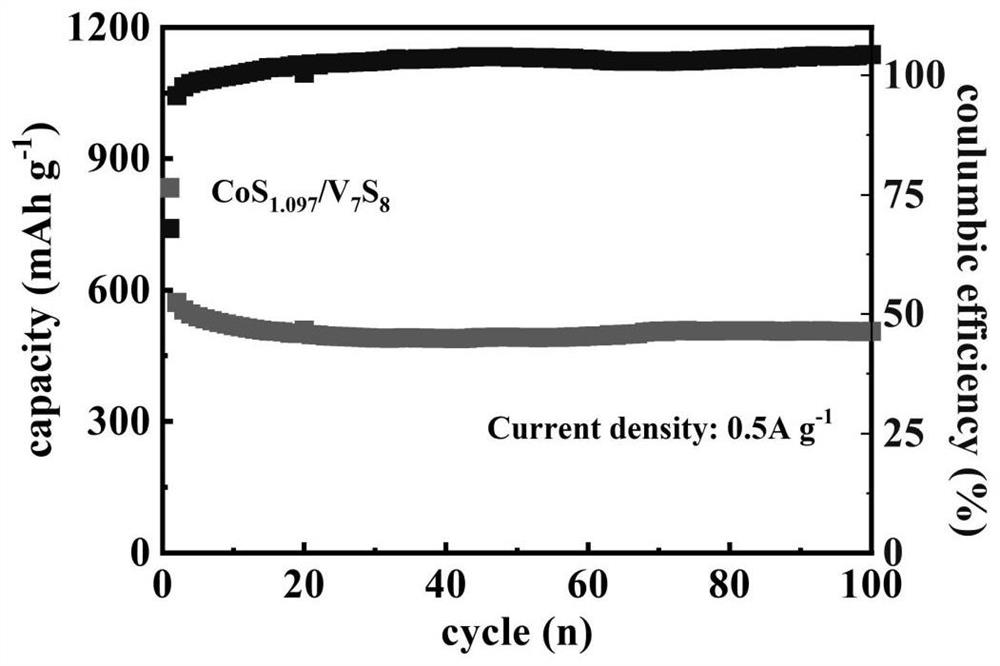

[0026] The cobalt vanadium sulfide electrode material prepared in Example 1 was characterized by SEM and electrochemical performance test. from figure 1 The detection results show that the prepared cobalt-vanadium sulfide material is a nano-flower formed by stacking a lamella structure, and the thickness of the lamella is about 20-50 nanometers. Depend on figure 2 It can be seen that the prepared cobalt vanadium su...

Embodiment 2

[0028] 0.75mmol CoCl 2 ·6H 2 O, 0.25 mmol VCl 3 , 15mmol urea, 2.5mmol TAA were added into deionized water, and after magnetic stirring was uniform, the mixed solution was transferred to the substrate of the polytetrafluoroethylene reactor, and further reacted at a high temperature of 120 ℃ for 8h, the slurry was filtered through a microporous membrane, Water and ethanol are repeatedly washed to remove impurities, and the final product is dried in an oven overnight, and the solid is ground to obtain the final cobalt vanadium sulfide electrode material.

Embodiment 3

[0030] 0.5mmol CoCl 2 ·6H 2 O, 0.5 mmol VCl 3 , 30 mmol urea, 1 mmol TAA were added to deionized water, and after magnetic stirring was uniform, the mixed solution was transferred to the substrate of a polytetrafluoroethylene reactor, and further reacted at a high temperature of 160 ° C for 24 h, the slurry was filtered through a microporous membrane, and the water Repeated washing with ethanol to remove impurities, the final product is dried in an oven overnight, and the solid is ground to obtain the final cobalt vanadium sulfide electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com