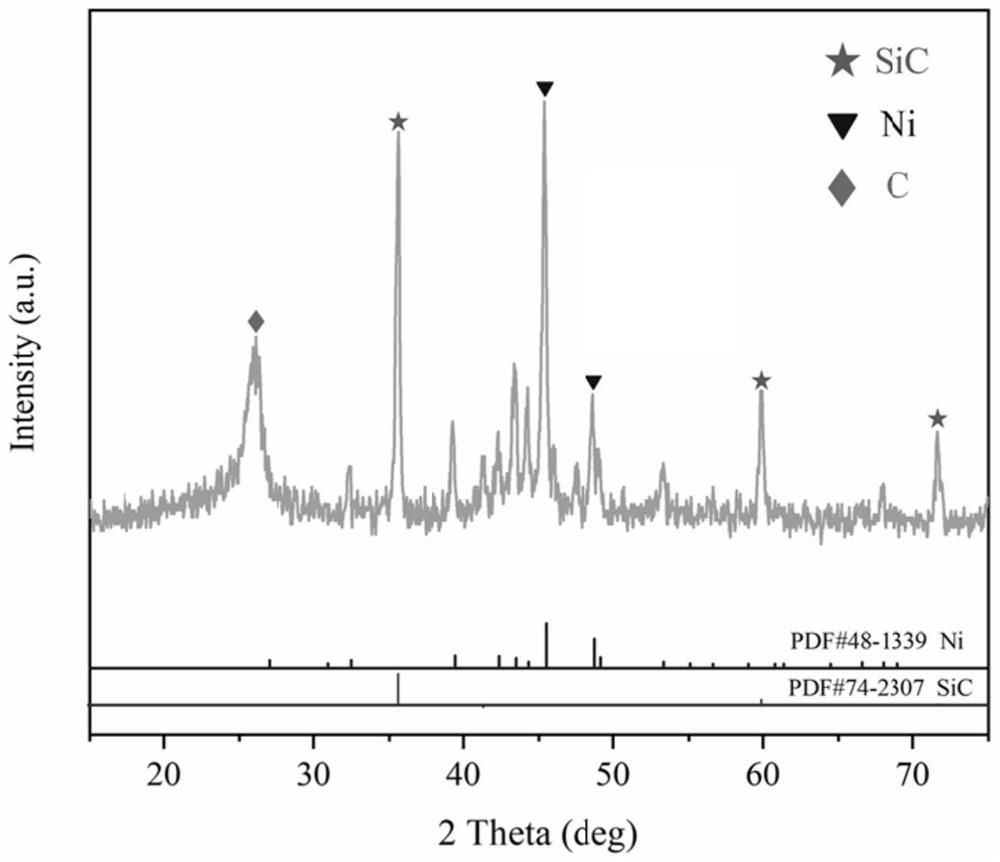

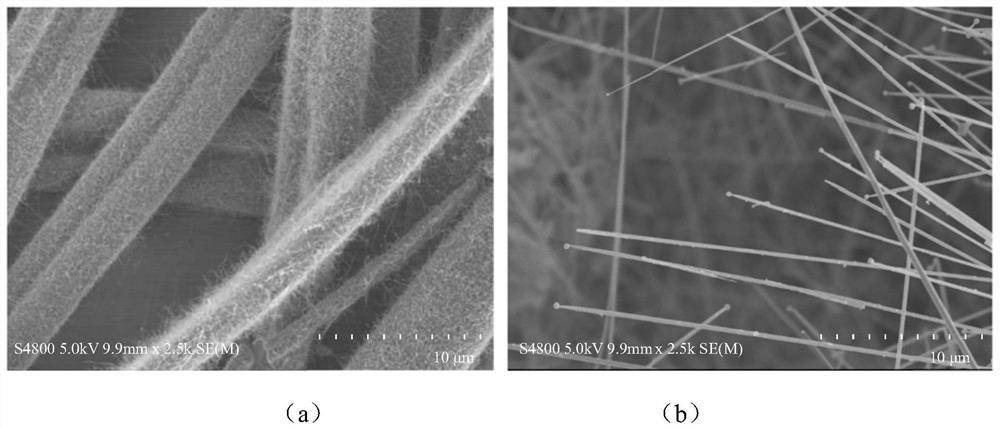

Preparation method of Cf/SiCnws/Ni composite material

A technology of composite materials and nickel sources, applied in nanotechnology for materials and surface science, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of long preparation cycle and complicated preparation process, and achieve The effect of short preparation cycle, low process cost and large aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Mix 4 ml of ethanol and 9 ml of tetrahydrofuran, stir evenly to obtain a mixed solvent; slowly add 1 g of polyvinylpyrrolidone and 1 g of polycarbosilane to the mixed solvent, stir evenly at room temperature, add 2 mmol of nickel acetate tetrahydrate, and stir for 12 hours to obtain blue-green Viscous solution, i.e. precursor solution;

[0043] 2) Electrospinning the prepared precursor solution, the distance between the needle and the collector in the electrospinning process is 15cm, the voltage is 16kv, and the rotational speed is 700r / min; the carbon nanofiber precursor is obtained;

[0044] 3) The carbon nanofiber precursor was heated to 280°C at a heating rate of 1°C / min, pre-oxidized at 280°C for 2 hours, and then cooled to room temperature with the furnace; then carbonized at a high temperature of 1300°C, with a heating rate of 5°C / min. After reaching 1000 °C and then rising to 1300 °C at 3 °C / min, the high temperature carbonization reaction time is 2 h, and th...

Embodiment 2

[0046] 1) Mix 3ml of ethanol and 9ml of tetrahydrofuran, stir evenly to obtain a mixed solvent; slowly add 1 g of polyvinylpyrrolidone and 1 g of polycarbosilane to the mixed solvent, stir evenly at room temperature, add 2 mmol of nickel acetate tetrahydrate, and stir for 12 hours to obtain a blue-green sticky solution. Thick solution, that is, the precursor solution;

[0047] 2) Electrospinning the prepared precursor solution, the distance between the needle and the collector in the electrospinning process is 15cm, the voltage is 16kv, and the rotational speed is 600r / min; the carbon nanofiber precursor is obtained;

[0048] 3) The carbon nanofiber precursor was heated to 280°C at a heating rate of 1°C / min, and pre-oxidized at 280°C for 2 hours; after carbonization at a high temperature of 1300°C, the heating rate was raised to 1000°C at a heating rate of 5°C / min and then at 3°C. / min was raised to 1300°C, the reaction time was 1h, and then cooled to room temperature with the...

Embodiment 3

[0050] 1) Mix 4ml of ethanol and 9ml of tetrahydrofuran, stir evenly to obtain a mixed solvent; slowly add 1g of polyvinylpyrrolidone and 1g of polycarbosilane, stir at room temperature and then add 3mmol of nickel acetate tetrahydrate, and stir for 12h to obtain a blue-green viscous solution , the precursor solution;

[0051] 2) Electrospinning the prepared precursor solution, the distance between the needle and the collector in the electrospinning process is 16cm, the voltage is 16kv, and the rotational speed is 700r / min; the carbon nanofiber precursor is obtained;

[0052] 3) The carbon nanofiber precursor was heated up to 300°C at a heating rate of 1°C / min, pre-oxidized at 300°C for 3 hours, and then cooled to room temperature with the furnace; after carbonization at a high temperature of 1400°C, the heating rate was 5°C / min. After reaching 1000°C, the temperature was raised to 1400°C at 3°C / min, the reaction time was 2h, and then cooled to room temperature with the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com