Heavy medium material for enhancing coagulation-adsorption synergistic effect and preparation method thereof

A synergistic, dense medium technology, applied in chemical instruments and methods, adsorption water/sewage treatment, inorganic chemistry, etc., can solve the problems of difficult to effectively remove dissolved organic pollutants, large footprint, long residence time, etc. Achieve the effects of simple and feasible preparation method, low production cost and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

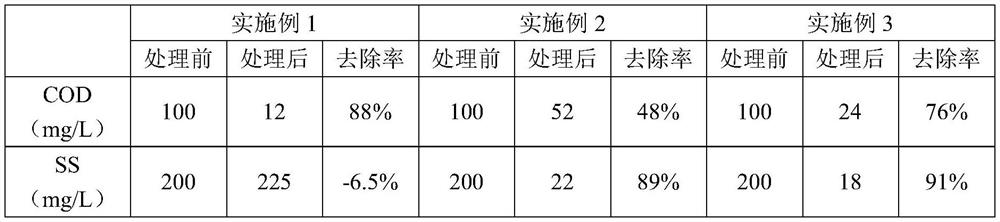

Examples

preparation example Construction

[0032] the Fe 3 O 4 The preparation of @rGO composites adopts a simple solvothermal method, which includes the following steps:

[0033] Step S21, measuring and quantifying the prepared graphene oxide suspension with a concentration of 1.0 g / L, and ultrasonically treating it for 3 hours to make it uniformly dispersed;

[0034] Step S22, weigh quantitative iron salt (FeCl 3 , ferric sulfate or ferric nitrate) and dissolve with a small amount of water, join in the graphene oxide suspension that dispersion is completed, stir 6 hours, form the first solution that iron salt concentration is 2.0~8.0g / L;

[0035] Step S23, transfer the first solution to the three-necked flask, add a small amount of hydrazine hydrate (as a reducing agent), continue stirring, and heat to 90-100 ° C; wherein, the consumption ratio of iron salt to hydrazine hydrate is 2-3g: 0.06-0.1mL.

[0036] Step S24, adding a quantitative ammonium carbonate solution to the three-necked flask, maintaining at 90-10...

Embodiment 1

[0043] S1: Weigh 2g graphite powder and add it to 27mL of H 3 PO 4 (mass concentration is 85%), carry out mechanical stirring to form the first solution;

[0044] S2, slowly adding 240 mL of concentrated sulfuric acid to the first solution, and continuing to stir to form a second solution;

[0045] S3, 12g KMnO 4Slowly added to the second solution, heated to 50°C, maintained for 12 hours and then cooled to room temperature to form a third solution;

[0046] S4, transfer the third solution to an ice-water bath, and add 2 mL mass fraction of 30% H 2 O 2 Add it slowly, observe that its color changes from brown to bright yellow, and synthesize graphene oxide solution containing impurities.

[0047] S5, the synthesized graphene oxide is repeatedly centrifuged and washed with hydrochloric acid having a concentration of 20%, and the finally obtained brown viscous substance is freeze-dried to obtain graphene oxide.

[0048] S6, weigh 2 g of the prepared graphene oxide into a sim...

Embodiment 2

[0056] S1, measure 37mL of the graphene oxide suspension in Example 1 with a prepared concentration of 1.0g / L, and ultrasonically treat it for 3 hours to make it evenly dispersed to obtain a graphene oxide suspension;

[0057] S2, weigh 0.25g FeCl 3 And dissolved with a small amount of water, added to the dispersed graphene oxide suspension, stirred for 6 hours to form FeCl 3 The first solution with a concentration of 5.0 g / L;

[0058] S3, transfer the first solution to a three-necked flask, add 2 drops (0.04 mL) of hydrazine hydrate, continue stirring, and heat to 100° C.;

[0059] S4, add a quantitative ammonium carbonate solution to the three-necked flask, maintain at 100° C. for 3 hours, and after cooling to room temperature, repeat centrifugal washing with distilled water and ethanol respectively;

[0060] S5, after drying the washed material in a vacuum drying oven at 80°C for 12 hours, and then annealing at 500°C for 3 hours under nitrogen protection, a heavy medium m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com