Method for preparing phosphatidylserine without organic solvent

A technology of phosphatidylserine and organic solvents, which is applied in the field of phospholipids, can solve the problems of high cost, difficulty in recycling and separating organic solvents, residues of solvents and plasticizers in products, etc., and achieves the effect of simple process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

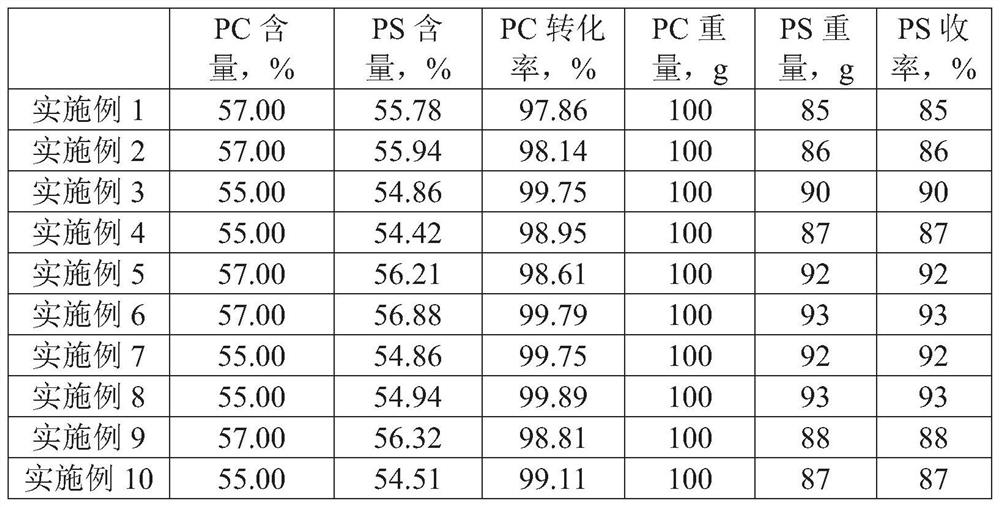

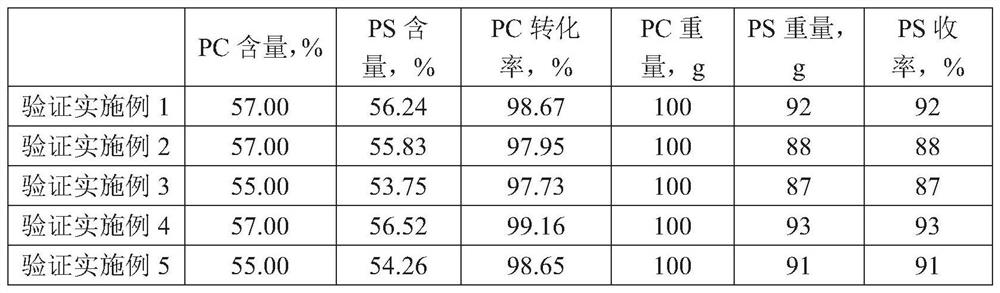

Examples

Embodiment 1

[0022] Prepare 540mL of enzyme-containing aqueous solution, the enzyme activity of phospholipase D in the enzyme solution is 5.0U / mL, and the pH is adjusted to 6.7;

[0023] Add 100g soybean lecithin raw material (phosphatidylcholine content is 57%) and 80g L-serine into the enzyme-containing aqueous solution, homogenize and stir evenly, and react at 42°C for 14 hours;

[0024] After the reaction was completed, 540 mL of water was added to the reaction solution, the serine was dissolved by stirring, and the aqueous phase was centrifuged to obtain 180 g of centrifugal precipitation;

[0025] Wash the centrifugal precipitation with 900 mL of pure water, separate the water phase by centrifugation, filter and concentrate the water phase of about 1980 mL of the two centrifugal separation membranes (reverse osmosis membrane) to 300 mL, and obtain the L-serine aqueous solution for the next batch of reactions. The second centrifugal precipitation is 180 g ;

[0026] The two centrifug...

Embodiment 2

[0028] Prepare 540mL of enzyme-containing aqueous solution, the enzyme activity of phospholipase D in the enzyme solution is 5.0U / mL, and the pH is adjusted to 6.5;

[0029] Add 100 g of soybean lecithin raw material (the content of phosphatidylcholine is 57%) and 80 g of L-serine into the enzyme-containing aqueous solution, homogenize and stir evenly, and react at 42° C. for 16 hours;

[0030] After the reaction was completed, 540 mL of water was added to the reaction solution, the serine was dissolved by stirring, and the aqueous phase was centrifuged to obtain 180 g of centrifugal precipitation;

[0031] The centrifugal precipitate was washed with 940 mL of pure water, the water phase was separated by centrifugation, and the 2020 mL of the water phase separated by the two centrifugal separations was concentrated to 300 mL by membrane filtration to obtain an aqueous L-serine solution for the next batch of reactions, and the second centrifugal precipitation was 180 g;

[0032...

Embodiment 3

[0034] Prepare 540mL of enzyme-containing aqueous solution, the enzyme activity of phospholipase D in the enzyme solution is 5.5U / mL, and the pH is adjusted to 6.5;

[0035] Add 100g soybean lecithin raw material (phosphatidylcholine content is 55%) and 80g L-serine into the enzyme-containing aqueous solution, homogenize and stir evenly, and react at 42° C. for 16 hours;

[0036] After the reaction was completed, 540 mL of water was added to the reaction solution, the serine was dissolved by stirring, and the aqueous phase was centrifuged to obtain 186 g of centrifugal precipitate;

[0037] The centrifugal precipitate was washed with 930 mL of pure water, the water phase was centrifuged, and the water phase separated by two centrifugations was concentrated to 300 mL by membrane filtration of about 2010 mL, to obtain an aqueous L-serine solution for the next batch of reactions, and the second centrifugal precipitation was 180 g;

[0038] Vacuum freeze-drying to obtain 90 g of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com