High-strength ultrathin polyimide fabric and preparation method thereof

A technology of polyimide and polyimide fiber, which is applied in the direction of fabrics, textiles, dry-cleaning fiber products, etc., can solve the problems that high-performance polyimide ultra-thin fabrics are difficult to realize and fine denier weaving is difficult, etc. Achieve the effects of excellent mechanical properties, excellent flame retardant properties, and good weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

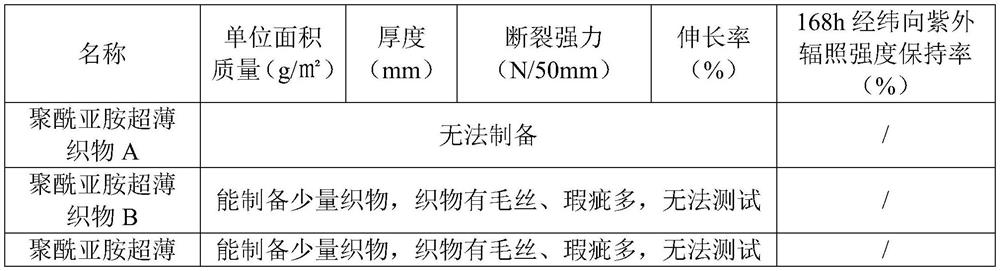

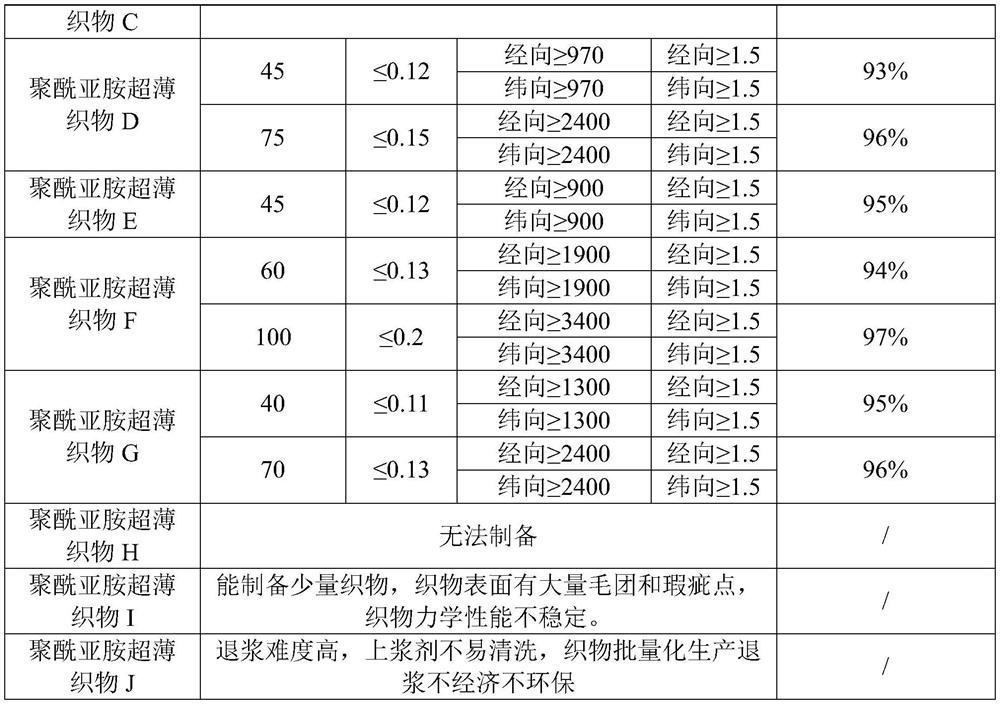

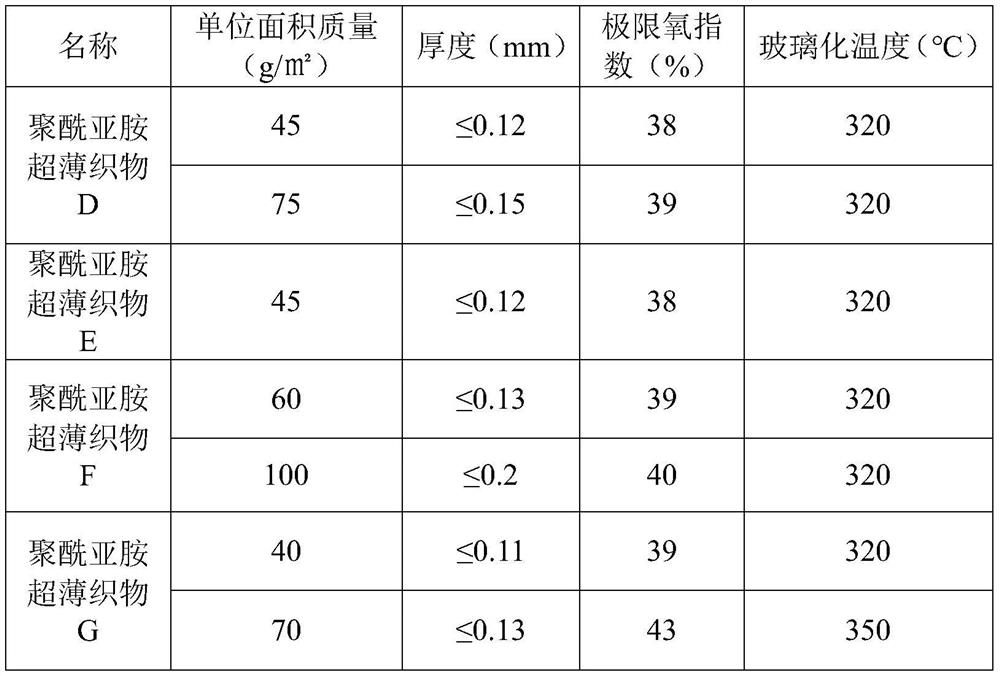

Embodiment 1

[0035]The 55D polyimide fibers with a breaking strength of 20.8cN / dtex were twisted S200 twists / meter. During the warping process, 7wt% concentration of water-based silicone sizing agent MP50E was used on the warp fibers for sizing treatment. The sizing time It is 25s, in which the weft yarn is twisted while sizing, twisting S100 twists / m, using 7wt% concentration of water-based silicone sizing agent MP50E for sizing treatment, and the sizing time is 20s. After the warp yarns are healed, the loom is used for weaving, and the woven fabric is ultrasonically desized. After 4 washings, the first washing adds desizing enzyme. The pulp tanks are equipped with ultrasonic devices, steam drum drying treatment at 100° C., and the winding speed is controlled at 20 m / min to obtain polyimide ultra-thin fabric D.

Embodiment 2

[0037] The 55D polyimide fibers with a breaking strength of 20.8cN / dtex were twisted S200 twists / meter. During the warping process, the warp fibers were sized with a water-based epoxy sizing agent DER WB6001 with a concentration of 8wt%. The sizing time For 40s, the weft yarn is twisted while sizing, twisting Z150 twists / m, using 8wt% concentration of water-based silicone sizing agent MP50E for sizing treatment, and the sizing time is 25s. After the warp yarns are healed, the loom is used for weaving, and the woven fabric is ultrasonically desized. After 4 washings, the first washing adds desizing enzyme. The pulp tanks are equipped with ultrasonic devices, steam drum drying treatment at 100° C., and the winding speed is controlled at 5 m / min to obtain polyimide ultra-thin fabric E.

Embodiment 3

[0039] The 100D polyimide fibers with a breaking strength of 20.8cN / dtex were twisted with S100 twists / meter. During the warping process, 4wt% concentration of water-based silicone sizing agent SH9608-A was used on the warp fibers for sizing treatment. The sizing time is 30s, and the weft yarn is twisted while sizing, twisting S200 twists / m, and using 4wt% concentration of water-based silicone sizing agent SH9608-A for sizing treatment, and the sizing time is 20S. After the warp yarns are healed, the loom is used for weaving, and the woven fabric is ultrasonically desized. After 4 washings, the first washing adds desizing enzyme. The pulp tanks are equipped with ultrasonic devices, steam drum drying treatment at 100° C., and the winding speed is controlled at 10 m / min, so that the polyimide ultra-thin fabric F is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Mass per unit area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com