Membrane for an electrochemical device, electrochemical device comprising the membrane, and method of manufacturing an

A battery and secondary battery technology, applied in electrolyte battery manufacturing, electrode manufacturing, battery electrodes, etc., can solve problems such as reducing ionic conductivity, and achieve the effects of improving dry adhesion and ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

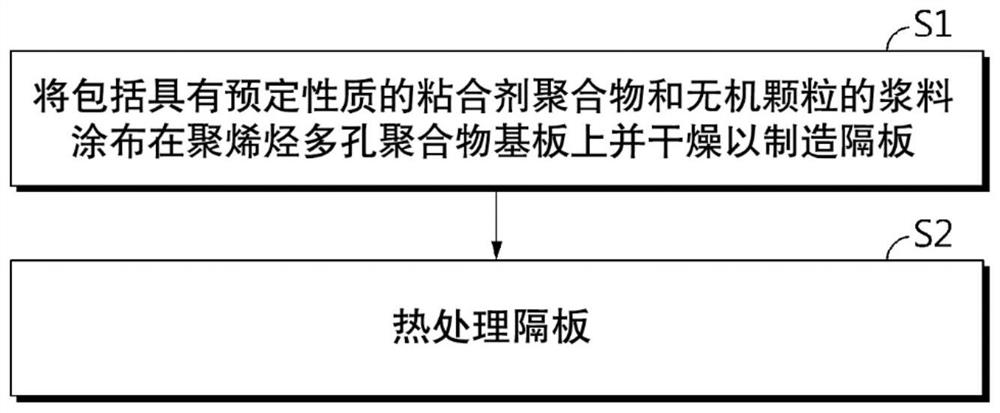

[0186] [Manufacture of separator]

[0187] Aluminum hydroxide (Al(OH) as inorganic particles 3 ) and polyvinylidene fluoride hexafluoropropylene (PVDF-HFP, weight average molecular weight: 700,000, HFP content: 10%) as a binder polymer were added to an acetone solvent in a weight ratio of 80:20 to prepare porous coating slurry.

[0188] The prepared slurry for forming a porous coating layer was coated on both surfaces of a 9 μm thick polyethylene porous polymer substrate (porosity: 43%, air permeation time: 110 sec, resistance 0.45 ohm) by dip coating and at 23 Drying was carried out under the conditions of ℃ and 40% relative humidity to produce the initial separator with the porous coating.

[0189] Subsequently, the initial separator was wetted in dimethyl carbonate as an organic solvent, and heat-treated at 80° C. for 3 hours to manufacture the final separator.

Embodiment 2

[0191] The separator was manufactured by the same method as in Example 1, except that polyvinylidene fluoride hexafluoropropylene (PVDF-HFP, weight average molecular weight: 700,000, HFP content: 15%) was used as a binder polymer instead of polyvinylidene fluoride hexafluoropropylene (PVDF-HFP, weight average molecular weight: 700,000, HFP content: 10%).

experiment example 1

[0218] The ionic conductivities of the separators manufactured in Examples 1 to 2 and Comparative Examples 1 to 6 were measured and compared.

[0219] The ionic conductivity of the separator was measured as follows: coin half-cells were fabricated using the separator alone and impregnated with an organic solvent including ethylene carbonate (EC) and dimethyl carbonate (DMC) in a volume ratio of 3:7 and 1.0 M LiPF 6 of non-aqueous electrolytes.

[0220] [Table 1]

[0221]

[0222] from Table 1 and Figure 4 It can be seen that Comparative Examples 1 to 2, which were not subjected to the heat treatment process, had lower separator ionic conductivity than Examples 1 to 2, which were subjected to the heat treatment process. Figure 4 The level of ionic conductivity improvement as a function of comonomer content is shown. Furthermore, from Figure 4 As can be seen from Comparative Examples 4 and 6 in Table 1, even after the heat treatment process was performed, when the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com