Process for enriching lithium in salt lake brine

A salt lake brine and enrichment technology, applied in the field of separation and recovery of magnesium and lithium in salt lake brine, can solve the problems of ion enrichment efficiency, process cost increase, osmotic pressure increase, etc., so as to reduce energy consumption and membrane fouling. The effect of blocking and improving the concentration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

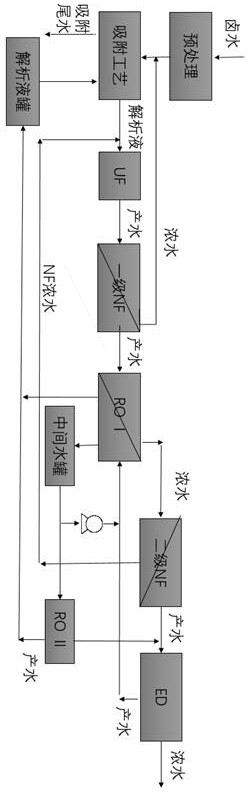

Image

Examples

Embodiment Construction

[0033] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the following examples will be further described. It should be understood that the following examples are only used to illustrate the present invention and not to limit the scope of the present invention. In the examples, the methods used are conventional methods unless otherwise specified, and the equipment used can be obtained through commercial channels.

[0034] After the salt lake brine is filtered, adsorbed and decomposed, the concentration of lithium ions in the desorption solution is 800 mg / L, the concentration of magnesium ions is 400 mg / L, the mass ratio of magnesium ions to lithium ions is 1:2, and the salt content is 7800 mg / L. In this example, the flow rate is 250m 3 / h.

[0035] In the embodiment, the recovery rate of lithium ions at each stage is calculated in the following manner: recovery rate of lithium ions=(water production amount×lithium ion co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com