Compound for treating cyclohexane organic waste liquid and preparation method thereof

A technology for organic waste liquids and compounds, which is applied in the fields of chemical synthesis and supramolecular chemistry, and can solve problems such as safety threats, operator poisoning, and increased warehouse construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1) Dissolve 12.0 g of cholesterol formyl chloride and 5.0 g of ethylenediamine in 600 mL of chloroform, stir at 35°C for 20 hours, spin dry the reaction solution under reduced pressure, recrystallize with methanol, filter, and vacuum dry to prepare N-cholesterylformylethylenediamine;

[0050] 2) Weigh 7.0g of N-cholesterylformylethylenediamine, 7.0g of oleic acid, and 8.5g of N,N'-dicyclohexylcarbonimide and dissolve it in 900mL of chloroform, stir at 30°C for 55 hours, and mix the reaction solution. Spin dry under reduced pressure, recrystallize with acetonitrile, filter, and dry in vacuo to prepare N-(N-cholesterylformyl)-ethanediyl-9-octadecenoic acid amide.

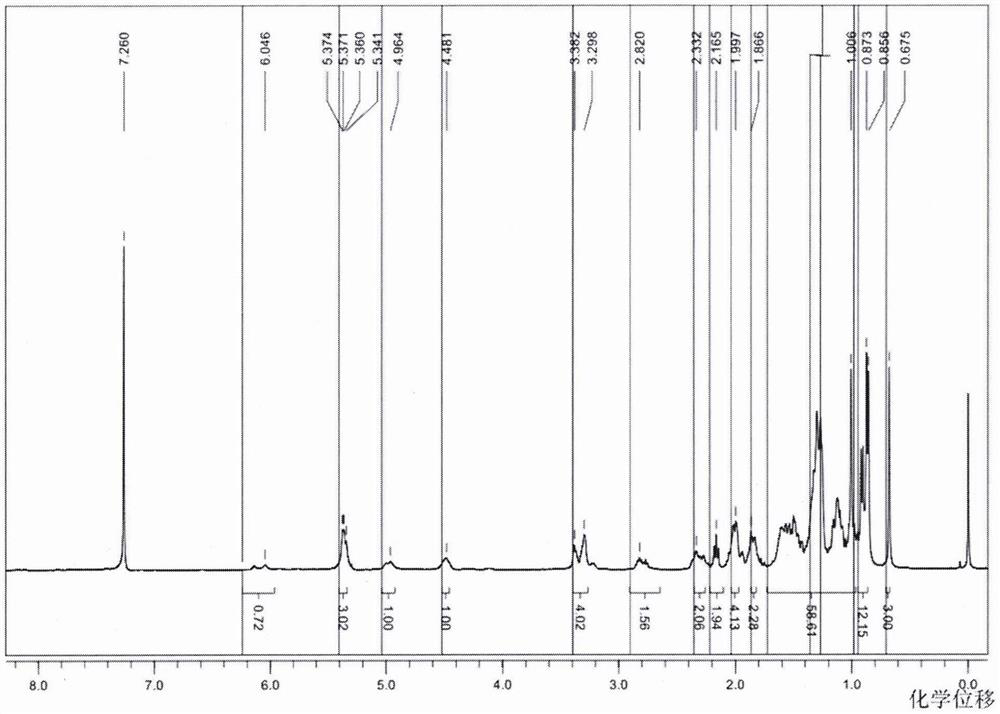

[0051] figure 1 It is the hydrogen nuclear magnetic resonance spectrum of N-(N-cholesterylformyl)-ethylenediyl-9-octadecenoic acid amide prepared in Example 1. The integral areas of all characteristic peaks in the spectrum are consistent with the number of hydrogens in the chemical formula, and there are no i...

Embodiment 2

[0053] 1) Dissolve 15.0 g of cholesterol formyl chloride and 6.5 g of ethylenediamine in 600 mL of chloroform, stir at 38°C for 22 hours, spin dry the reaction solution under reduced pressure, recrystallize with methanol, filter, and vacuum dry to prepare N-cholesterylformylethylenediamine;

[0054] 2) Weigh 9.0 g of N-cholesteryl formylethylenediamine, 10.5 g of oleic acid, and 13.0 g of N,N'-dicyclohexylcarboximide and dissolve it in 1200 mL of chloroform, and stir at 30°C for 70 hours. Spin dry under reduced pressure, recrystallize with acetonitrile, filter, and dry in vacuo to prepare N-(N-cholesterylformyl)-ethanediyl-9-octadecenoic acid amide.

Embodiment 3

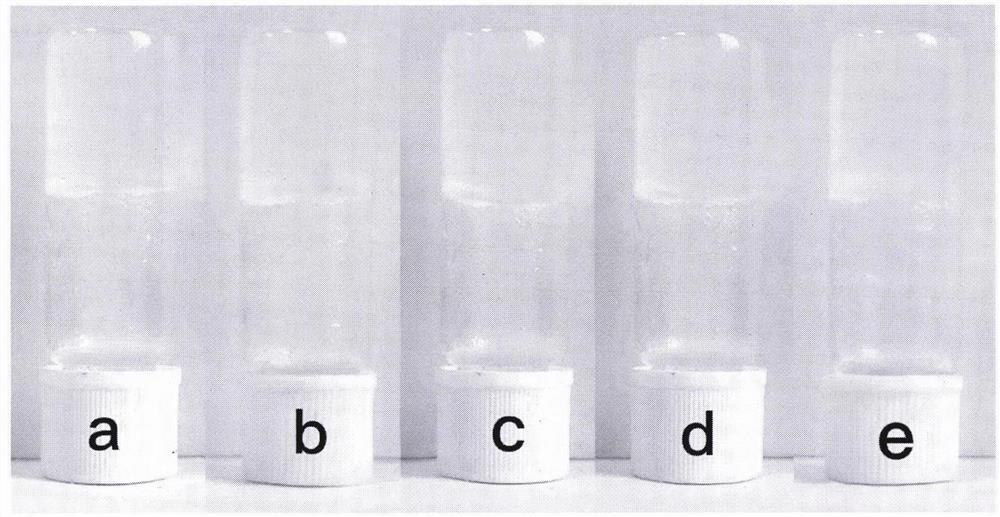

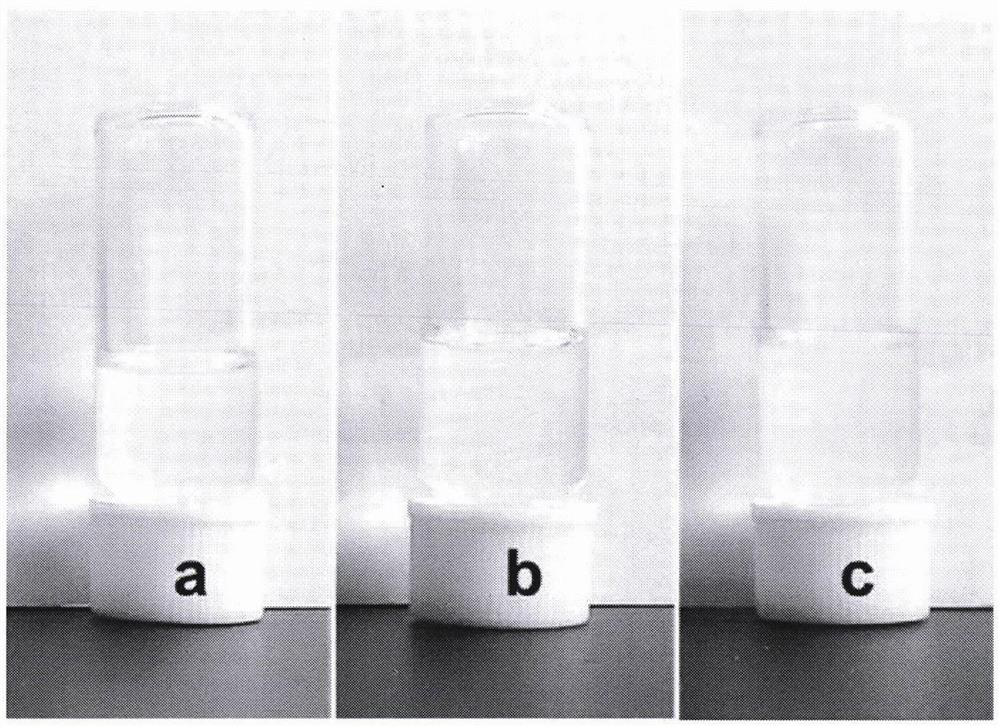

[0056] 5 mg of N-(N-cholesterylformyl)-ethanediyl-9-octadecenoic acid amide prepared in Example 1 was added to 1 mL of cyclohexane, the compound was dissolved by simple stirring at room temperature, and allowed to stand for 20 minutes to form a stable organogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com