Preparation process of environment-friendly and energy-saving PP material

An environmental protection, energy saving and preparation technology technology, applied in the field of plastic manufacturing, can solve the problems of large-scale industrial production, complex by-product treatment process, affecting production efficiency, etc., to optimize the feeding sequence, improve transparency and quality, and improve fluidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

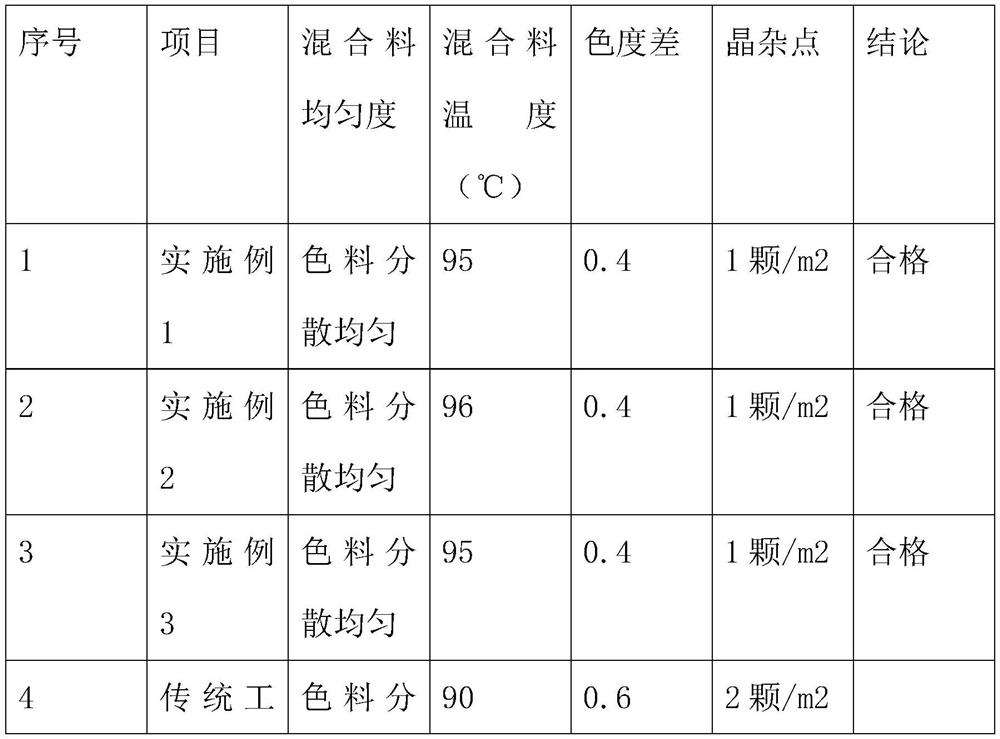

Examples

Embodiment 1

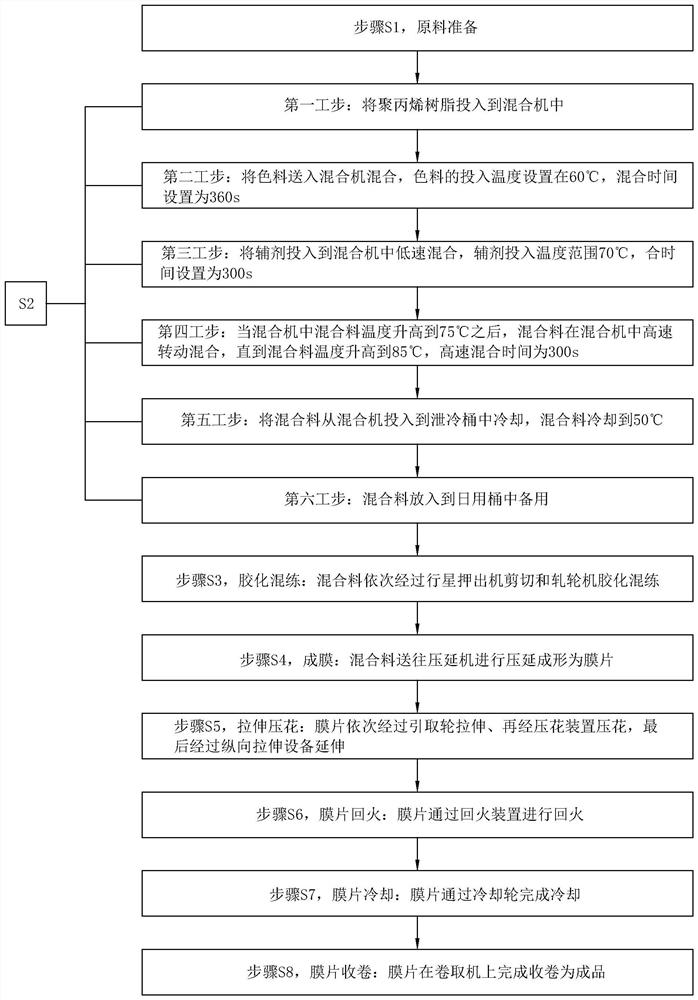

[0043] A preparation process of environmental protection and energy saving PP material, such as figure 1 shown, including the following steps:

[0044] Step S1, raw material preparation: prepare polypropylene resin, natural calcium powder, adjuvant, and colorant;

[0045] Among them, the raw materials are prepared according to the weight components: 50 parts of polypropylene resin, 20 parts of natural calcium powder, 0.5 part of auxiliary agent, and 0.003 part of colorant.

[0046] Specifically, the adjuvant includes a lubricant and a modifier, the lubricant is glycerol fatty acid triester; the modifier is copolymerized PP.

[0047] Step S2, mixing raw materials, including the following steps:

[0048] The first step: put the polypropylene resin into the mixer.

[0049] The second step: the color material is sent to the mixer for mixing, the input temperature of the color material is set at 60°C, and the mixing time is set at 360s.

[0050] The third step: put the adjuvant...

Embodiment 2

[0061] A preparation process of environmental protection and energy saving PP material, such as figure 1 shown, including the following steps:

[0062] Step S1, raw material preparation: prepare polypropylene resin, natural calcium powder, adjuvant, and colorant;

[0063] Among them, the raw materials are prepared according to the weight components: 60 parts of polypropylene resin, 40 parts of natural calcium powder, 0.8 part of auxiliary agent, and 0.0003 part of colorant.

[0064] Specifically, the adjuvant includes a lubricant and a modifier, the lubricant is a mixture of glycerol fatty acid triester and alkyl fatty acid monoglyceride; the modifier is block copolymerized polypropylene (PP-B) and random copolymerized polypropylene (PP-R) mix.

[0065] Step S2, mixing raw materials, including the following steps:

[0066] The first step: put the polypropylene resin into the mixer.

[0067] The second step: the color material is sent to the mixer for mixing, the input temper...

Embodiment 3

[0079] A preparation process of environmental protection and energy saving PP material, such as figure 1 shown, including the following steps:

[0080] Step S1, raw material preparation: prepare polypropylene resin, natural calcium powder, adjuvant, and colorant;

[0081] Among them, the raw materials are prepared according to the weight components: 80 parts of polypropylene resin, 50 parts of natural calcium powder, 1 part of auxiliary agent, and 0.003 part of colorant.

[0082] Specifically, the adjuvant includes a lubricant and a modifier, the lubricant is a mixture of glycerol fatty acid triester and alkyl fatty acid monoglyceride; the modifier is block copolymerized polypropylene (PP-B) and random copolymerized polypropylene (PP-R) mix.

[0083] Step S2, mixing raw materials, including the following steps:

[0084] The first step: put the polypropylene resin into the mixer.

[0085] The second step: the color material is sent to the mixer for mixing, the input tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com