Preparation method of high-temperature-resistant ultra-narrow-frame mobile phone touch screen

A technology of touch screen and ultra-narrow edge, which is applied to the structure of telephone sets, the input/output process of data processing, and the protection of internal/peripheral computer components. Information leakage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

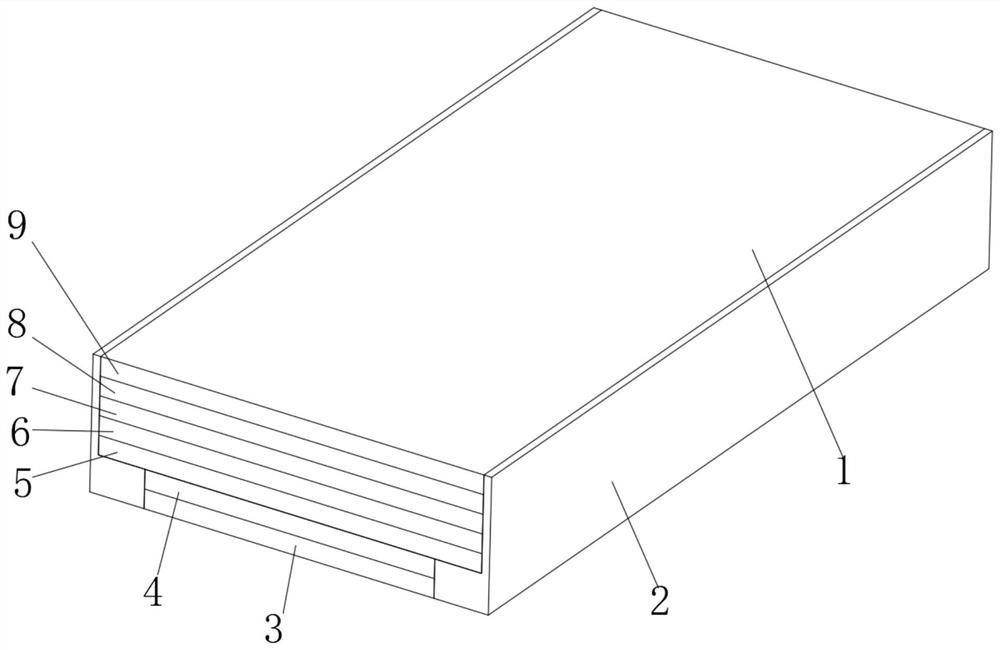

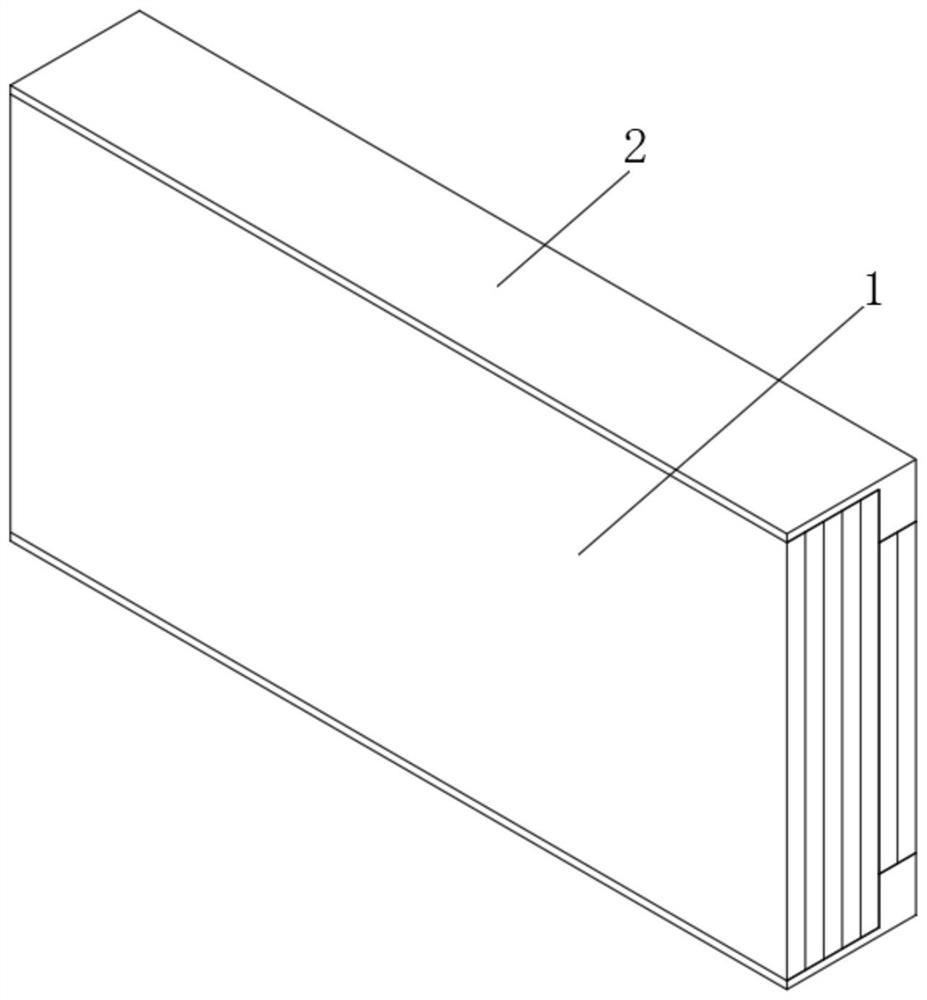

[0038] like Figure 1-4 As shown, a method for preparing a touch screen of a mobile phone with a high temperature resistance and an ultra-narrow frame includes a touch screen body 1 and an organic substrate 3. The preparation process of the touch screen body 1 is as follows:

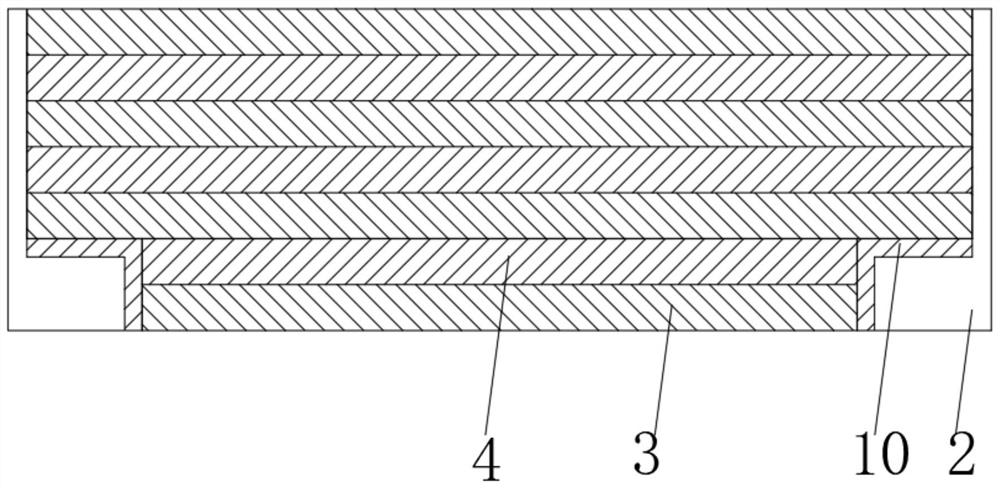

[0039] Sp1: The PET substrate 4 is arranged on the surface of the organic substrate 3, and the organic substrate 3 and the PET substrate 4 are stacked and mounted, and both sides of the organic substrate 3 and the PET substrate 4 are cut and processed, and the organic substrate 3 and the PET substrate 4 are cut and processed. Cut planes are formed on both sides, the organic substrate 3 includes graphene, a single layer of graphene is prepared on copper foil by chemical vapor deposition, and then a layer of polymethyl methacrylate is coated on the surface of the graphene, and the copper foil is etched to form Organic substrate 3.

[0040] Sp2: Coat the second ITO layer 10 on the surface of the cut surfac...

specific Embodiment 2

[0053] The difference from the first embodiment is that the PET substrate 4 is replaced with other transparent substrates of polymer materials.

[0054] like Figure 1-4 As shown, a method for preparing a touch screen of a mobile phone with a high temperature resistance and an ultra-narrow frame includes a touch screen body 1 and an organic substrate 3. The preparation process of the touch screen body 1 is as follows:

[0055] Sp1: Set other transparent substrates of polymer materials on the surface of the organic substrate 3, such as plexiglass, acrylic substrates, etc., and install the organic substrate 3 and the transparent polymer material substrates in an overlapping manner, and install the organic substrate 3 and the transparent polymer material substrates. The two sides of the organic substrate 3 and the two sides of the transparent substrate of polymer material are cut to form cut surfaces;

[0056] Sp2: Coat the second ITO layer 10 on the surface of the cut surface i...

specific Embodiment 3

[0062] The difference from the specific embodiment 1 is that different PVD coating gases are used, the color tone of the touch screen can be adjusted, and the mobile phone touch screen used by different groups of people can be prepared.

[0063] like Figure 1-4 As shown, a method for preparing a touch screen of a mobile phone with a high temperature resistance and an ultra-narrow frame includes a touch screen body 1 and an organic substrate 3. The preparation process of the touch screen body 1 is as follows:

[0064] Sp1: Set the PET substrate 4 on the surface of the organic substrate 3, and install the organic substrate 3 and the PET substrate 4 in an overlapping manner, and cut both sides of the organic substrate 3 and the PET substrate 4. Cut planes on both sides;

[0065] Sp2: Coat the second ITO layer 10 on the surface of the cut surface in step Sp1, and install the connecting frame 2, the connecting frame 2 is attached to the cut surfaces of the organic substrate 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com