Film resistor temperature sensor and its making process

A technology of temperature sensor and thin film resistor, used in thermometers, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve problems such as easy generation of pinholes, dust, bubbles, difficulty in adjusting printing characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

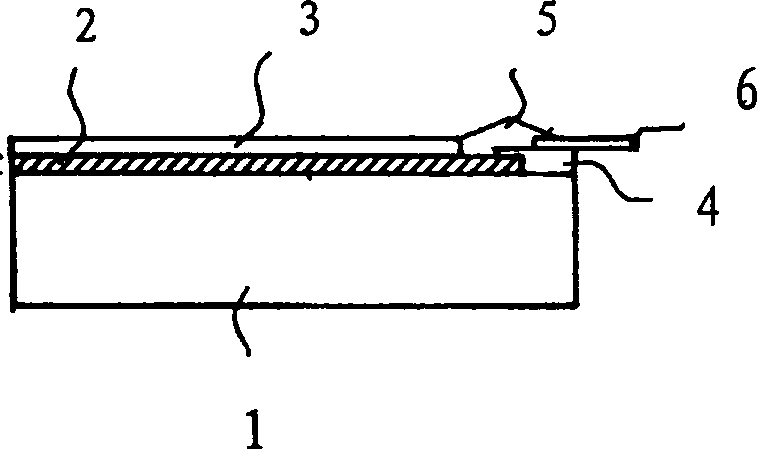

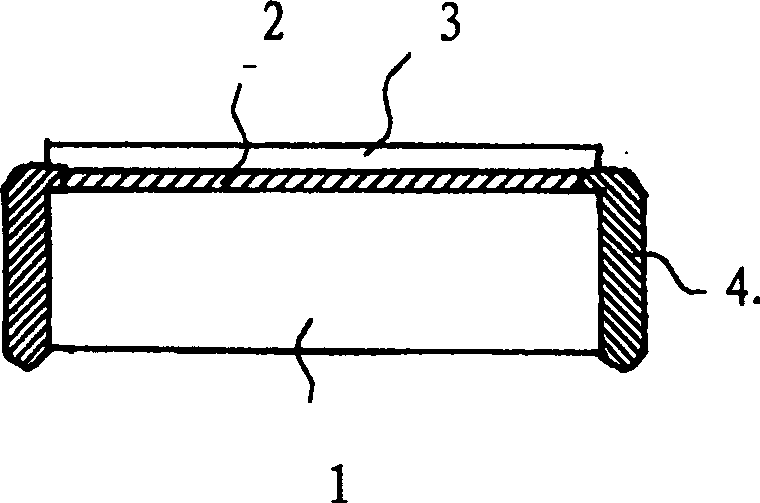

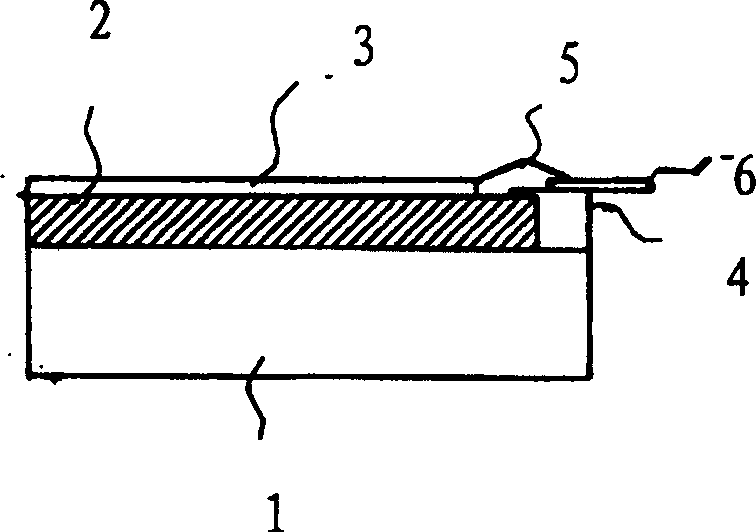

[0034] The hybrid platinum paste is different from the thick-film platinum resistor paste formed by mixing platinum powder and glass powder, because it uses the polymer bonding technology of platinum, so the film-forming property is very good. Technically, the thickness of the film is required to be 0.02um-2um, and the present invention adopts mixed slurry to make the temperature-sensing part. The 43% vulcanized turpentine platinum produced by Handan Ceramic Research Institute was heated at 190°C for 15 minutes, and the decomposition product was mixed with 4.3% vulcanized turpentine rhodium and 5.1% abietic acid bismuth by platinum: rhodium: bismuth=1: 0.0001: 0.003 Ratio, adding 20% by weight of polymethacrylic acid resin produced by Weihai Weixin Chemical Co., Ltd. and 5% by weight of cellulosolve and 10% by weight of terpineol and other solvents, stirring and mixing to obtain the required hybrid platinum slurry Material, the platinum slurry is evenly coated on the glazed ...

Embodiment 2

[0037] 43% sulfurized turpentine platinum and 35% sulfurized terpineol platinum produced by Handan Ceramic Research Institute were mixed in a ratio of 2:1, heated at 190°C for 15 minutes, and the decomposition product was mixed with 4.3% sulfurized turpentine rhodium, 3.8% The copper abietate is by platinum: rhodium: the ratio of copper=1: 0.0001: 0.001, adds the polymethacrylic acid resin that the Weihai Weixin Chemical Co., Ltd. of 20% by weight produces and the cellosolve of 5% by weight and 10% by weight Solvents such as terpineol, stirred and mixed evenly to obtain the required hybrid platinum slurry, and the platinum slurry was evenly coated on the glazed alumina substrate 1, and after sintering at 810°C for 30 minutes, a platinum-coated substrate was obtained. Repeat printing and sintering to obtain a thickened platinum-coated substrate; form the required pattern by photolithography and plasma etching to obtain the temperature-sensitive platinum resistor part 2, print an...

Embodiment 3

[0040] The 43% vulcanized turpentine platinum 190 ℃ of heating 15 minutes that Handan ceramics research institute produces, with decomposition product and 4.3% vulcanized turpentine rhodium, 5.1% bismuth abietate by platinum: rhodium: bismuth=1: 0.0003: 0.01 ratio Add 20% by weight of polymethacrylic acid resin produced by Weihai Weixin Chemical Co., Ltd. and 5% by weight of cellulosolve and 10% by weight of terpineol and other solvents, stir and mix to obtain the desired hybrid platinum Slurry, apply the platinum slurry evenly on the glazed alumina substrate 1, sinter at 850°C for 30 minutes to obtain a platinum-coated substrate, repeat printing and sintering to obtain a thickened platinum-coated substrate; Form the required pattern by etching to obtain the temperature-sensitive platinum resistance part 2, print and sinter the lead electrode 3, coat and sinter the glass encapsulation layer 4, laser correction to obtain the required resistance value, and cut and seal the termin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com