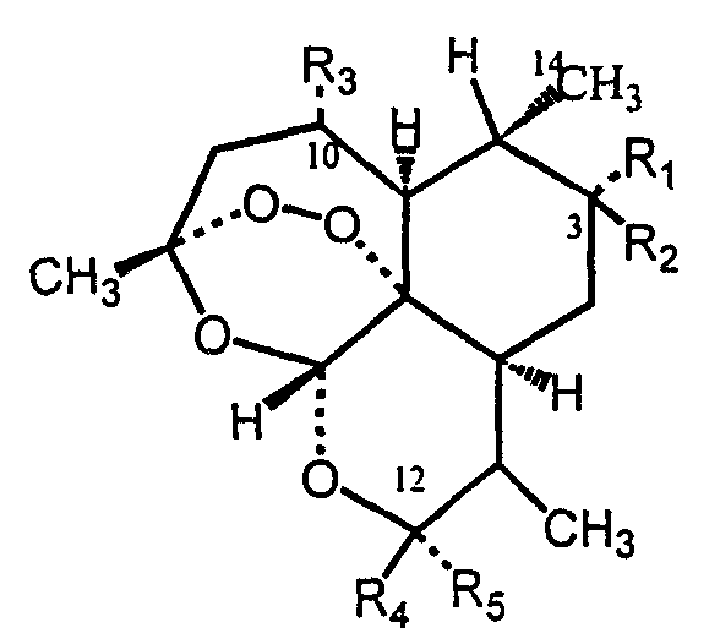

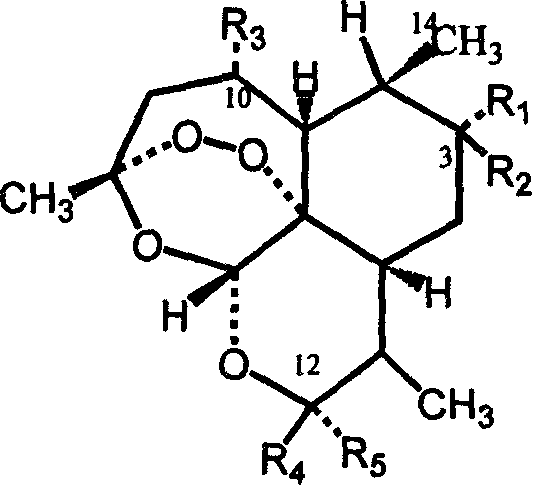

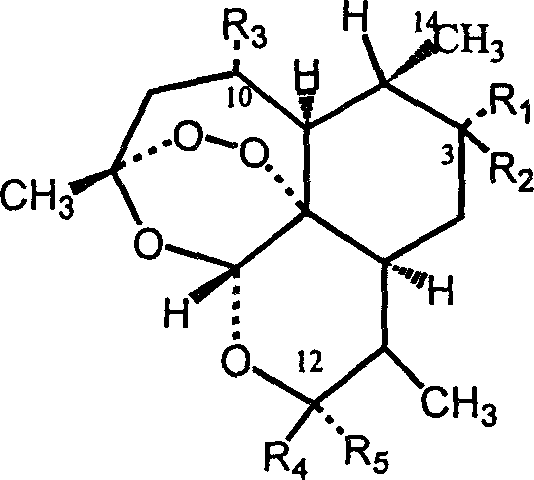

Biotransfer process for preparing artemisine compounds

A technology for artemisinin and compounds, which is applied in the field of biotransformation and preparation of artemisinin compounds, and can solve the problem of no other uses being retrieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Screening of microbial strains with transforming activity

[0048] In the present invention, 14 strains (strains) are transformed and screened, and the result shows that Streptomyces griseus (ATCC-13273) has strong transformation ability to artemisinin, dihydroartemisinin and artemether.

[0049] Liquid medium for strain screening—soybean flour glucose medium: take 20g of glucose, 5g of yeast extract, 5g of soybean flour, 5g of NaCl, K 2 HPO 4 5g, distilled water 1000mL, adjust the pH to 7.0 with 6N HCl. Pack in 150ml Erlenmeyer flasks, 25ml per bottle, sterilize at 121°C, 0.15Mpa for 20min.

[0050] When screening strains, the slant solid medium used for preserving strains is to add 1.5% agar to the above-mentioned liquid medium, heat and dissolve, then divide into 15mL test tubes with screw caps, and sterilize at 121°C and 0.15Mpa for 20min. , Obliquely cooled.

[0051] Strain preservation and activation

[0052] The strains were inoculated on the slant solid me...

Embodiment 2

[0081] Biotransformation of artemisinin compounds

[0082] Experimental Materials and Instruments

[0083] Microorganisms The microorganisms used in this experiment are Streptomyces griseus, the preservation number of which is ATCC-13273, which has been disclosed in US Patents 5,674,714, 5,213,971, and 5,169,755.

[0084] Reagents and reagents Artemisinin was prepared according to literature methods, see: Chen Yougen, Yu Boyang, etc., Extraction, separation and identification of artemisinin and its precursor compounds, Chinese herbal medicine, 2001; 32(4): 302-303, and identified by spectrum Its structure is consistent with the literature reports; dihydroartemisinin was purchased from Beijing Sixth Pharmaceutical Factory; artemether was purchased from Kunming Pharmaceutical Co., Ltd. The three compounds were respectively dissolved in acetone to make a solution with a concentration of 240 mg / mL, shaken well, and used as conversion substrates for later use.

[0085] Medium 20%...

Embodiment 3

[0120] Selection of Carbon Source, Nitrogen Source and Metal Ion in Artemisinin Microbial Transformation Medium

[0121] The main product of artemisinin transformed by microorganism Streptomyces griseus was screened, especially the transformation conditions of 3α-hydroxyartemisinin.

[0122] Medium:

[0123] Carbon source selection medium: 20% potato decoction 1000ml, carbon source (glucose or soluble starch, sucrose, maltose, citric acid, galactose, dextrin, corn flour, glycerin) 20g, yeast extract 5g, soybean powder 5g , KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 1.5g, VB 1 Trace amount (pH5.0~7.5).

[0124] Nitrogen source selection medium: 20% potato decoction 1000ml, glucose 20g, nitrogen source (peptone or beef extract, yeast extract, corn flour, soybean flour 10g, or urea, ammonium carbonate, sodium nitrate, L-lysine , DL-α-alanine is equivalent to sodium nitrate 2g / L), KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O 1.5g, VB 1 Trace amount (pH5.0~7.5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com