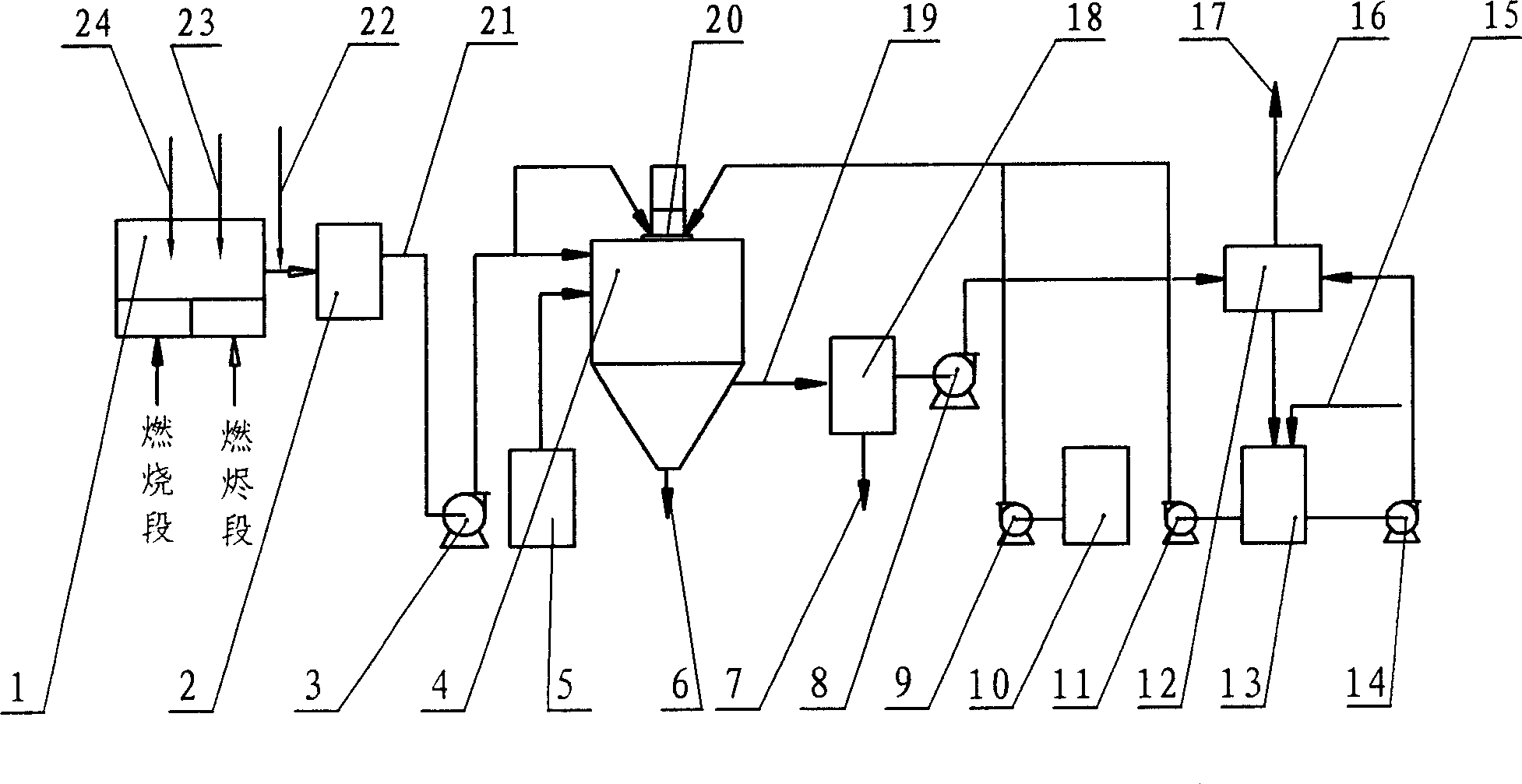

Smoke desulfuration denitrification dedust process and device

A flue gas and process technology, which is applied in the field of industrial furnace flue gas desulfurization, denitrification and dust removal process and equipment, can solve the problems of complicated process, ineffective utilization, and expensive equipment investment, and achieve simple process flow, low power consumption, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

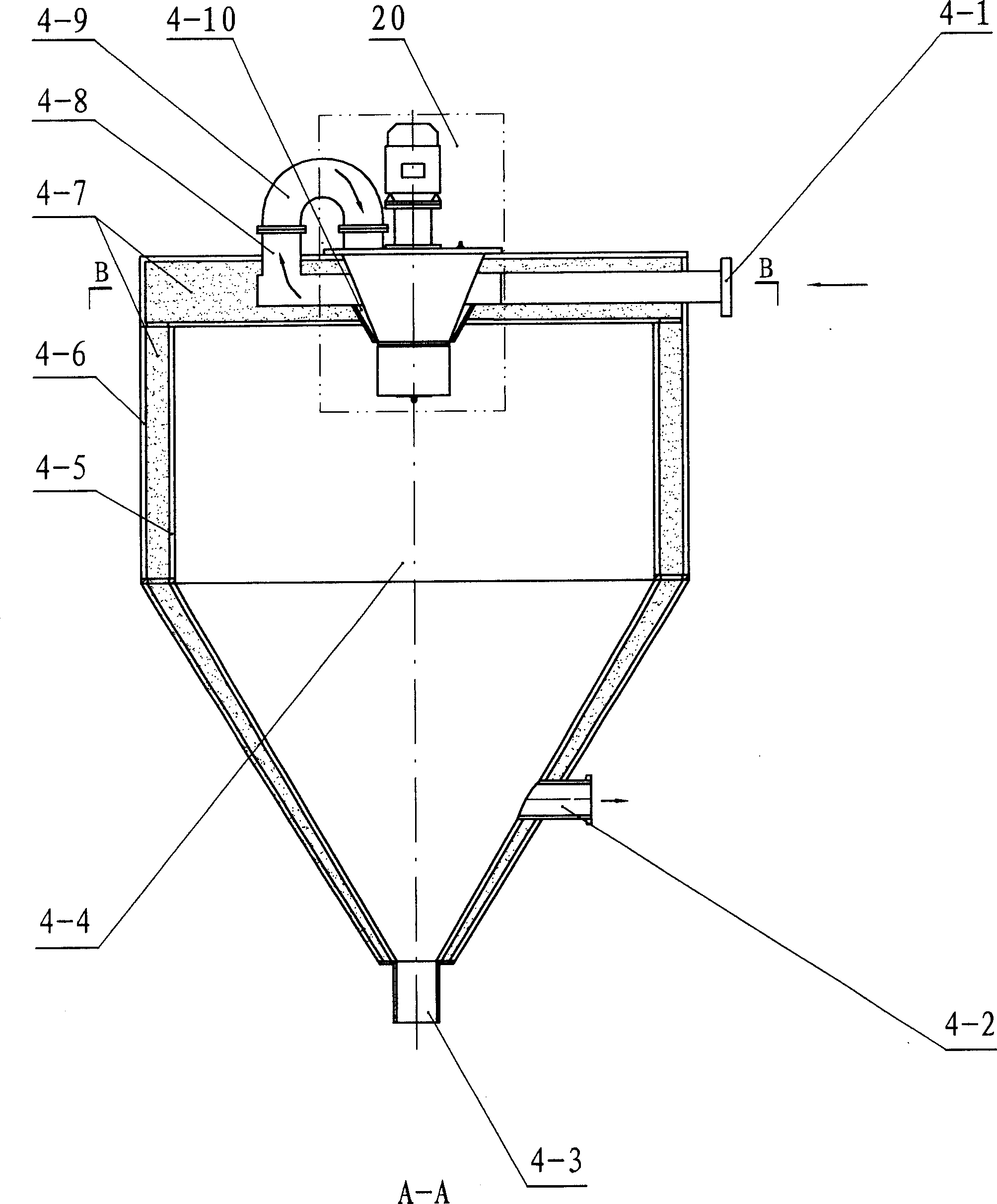

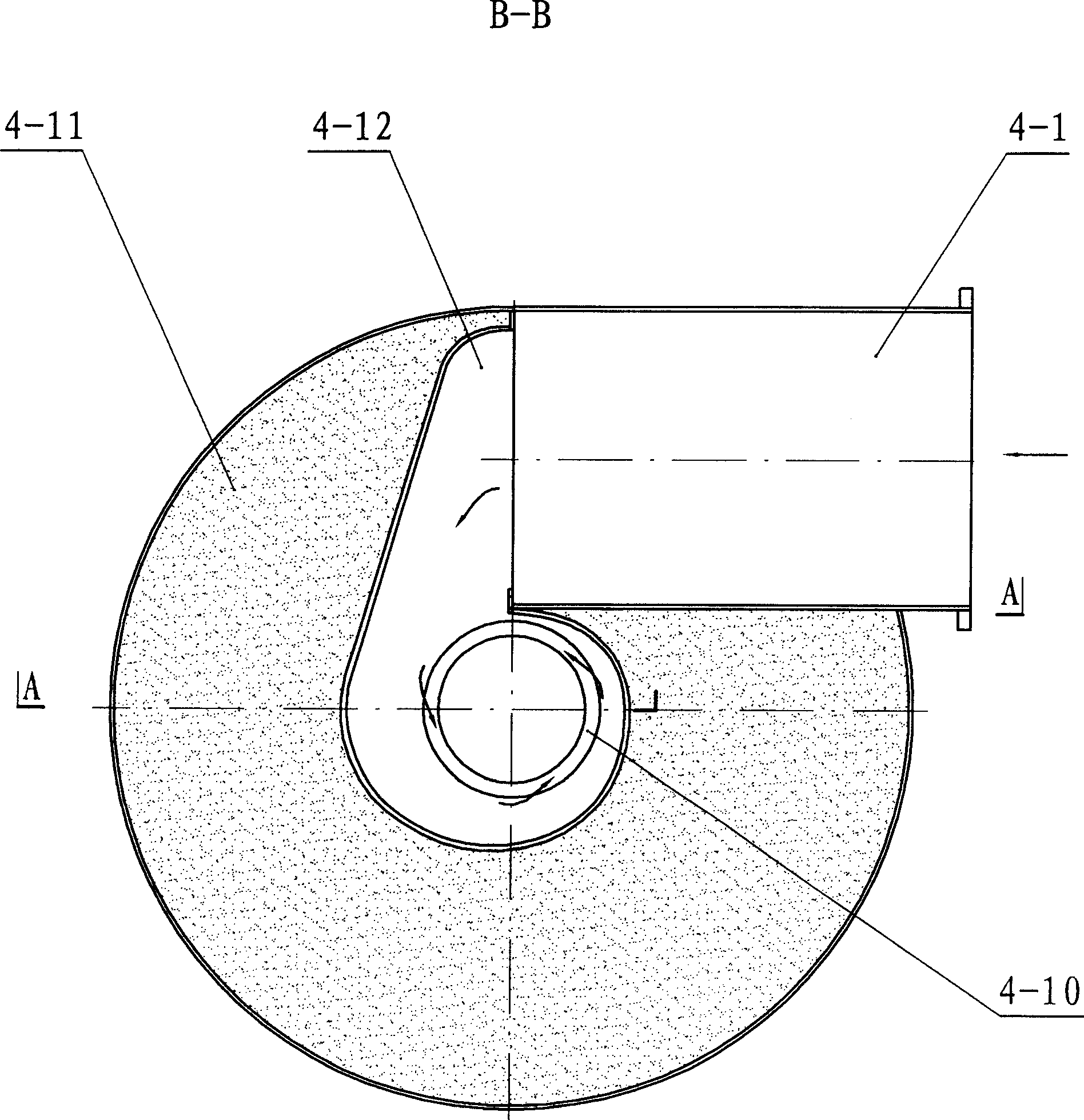

Method used

Image

Examples

Embodiment 1

[0080] Tested on DZL4-1.25-AIII type boiler; SO in flue gas 2 The content is 1760mg / M 3 , close the air intake door of the combustion section to make the coal burn in an oxygen-poor state, test the oxygen content in the flue gas with a flue gas comprehensive tester, make the excess air coefficient α = 0.7, and open the air door of the ember section to fully burn the coal As far as possible, measure the oxygen content in the flue gas, so that the excess air coefficient α = 1.2, and there is no black carbon in the slag. An air inlet is opened at the upper part of the combustion section 600mm above the grate, and the secondary air is sent in. The secondary air volume is 25% of the total air volume, forming a wind on the fire, so that the unburned volatiles are burned out; at the outlet of the furnace flue gas , the temperature of the flue gas is introduced into a nozzle in the area of 900 ° C, and a small amount of ammonia water is injected, and the NO X The molar ratio of am...

Embodiment 2

[0082] DZL4-1.25-AIII type boiler is used, when using Class III bituminous coal, under rated working conditions, SO in the flue gas 2 The content is 2840mg / M 3 , using the process of Example 1, the treated flue gas SO 2 The content is 70mg / M 3 . NO X The content is 170mg / M 3 , soot content is 35mg / M 3 (testing with flue gas composition tester) per hour ammonium sulfate output is 68.5kg, and ammonium sulfate water content and purity are with embodiment 1.

Embodiment 3

[0084] Still testing on the DZL4-1.25-AIII type boiler, when using Type III bituminous coal, under rated conditions, the SO in the flue gas 2 The content is 3410mg / M 3 The coal-fired, technological process is the same as embodiment 1, and the flue gas SO after treatment 2 The content is 80mg / M 3 ; The output of ammonium sulfate per hour is 82.5kg, NO X The content is 160mg / M 3 , soot content is 48mg / M 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com