Method for preparing hydrophobic noble metal nano granules using microwave

A technology of nanoparticles and precious metals, applied in the direction of coating, etc., can solve the problems of metal nanoparticles that cannot be applied to microwave radiation methods, cannot be mass-produced, easy to burn and volatilize, and achieve rapid preparation, small particle size, and dispersion Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

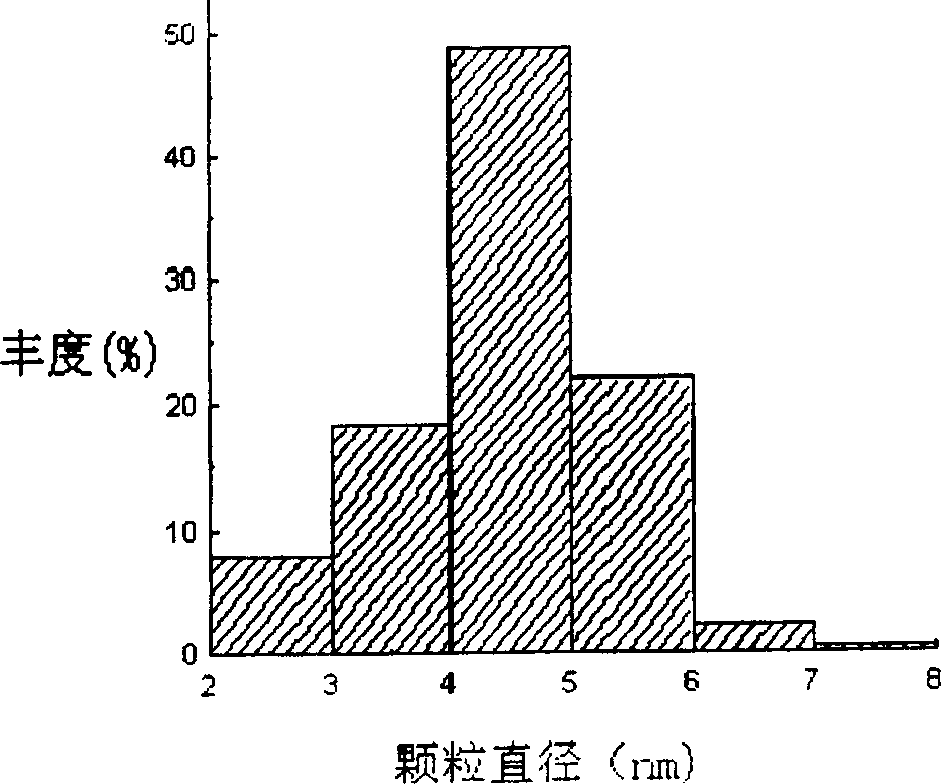

[0030]Preparation method of n-octadecylamine-protected gold nanoparticles. Use a pipette to draw 1.0ml of chloroauric acid solution into a beaker, heat and evaporate to dryness, put 0.05g of n-octadecylamine, then add 20ml of n-heptane, 1.0ml of ethanol with a molar concentration of 0.2M NaOH solution, the mol ratio of n-octadecylamine and chloroauric acid is 40:1, and the volume ratio of n-heptane and 0.2M NaOH in ethanol is 4:1. The system was ultrasonically oscillated for about 30 minutes, and the obtained system was an orange-yellow clear solution. Place the beaker in the center of the microwave tray and stir on medium speed for about 20 minutes. Then heat continuously for 60 seconds with a microwave oven, the frequency is 2450MHz, and the power is 750W, and the heating is stopped after the solution changes color. After continuing to stir for 30 minutes, a purple gold sol was obtained.

[0031] The obtained gold sol was rotary evaporated to nearly dryness, and absolute ...

Embodiment 2

[0033] Use a pipette to draw 1.0ml of chloroauric acid aqueous solution and place it in a beaker, heat and evaporate to a certain amount of n-tetradecyl mercaptan, then add 20ml of n-heptane, 4.5ml of absolute ethanol and 1.0ml of ethanol with 0.2M NaOH solution, the molar ratio of n-tetradecyl mercaptan to chloroauric acid is 20:1, and the volume ratio of n-heptane to absolute ethanol is 2:1. The system was ultrasonically oscillated for about 20 minutes to 1 hour, and the obtained system was an orange-yellow clear solution. Place the beaker in the center of the microwave tray and stir on medium speed for about 20 minutes. Then heat continuously for 60 seconds with a modified microwave oven, the frequency is 2450MHz, and the power is 80W. After the solution changes color, stop heating, stop heating, and continue stirring for 30 minutes to obtain a deep purple gold sol.

[0034] The obtained gold sol was rotary evaporated to nearly dryness, and absolute ethanol was added to it...

Embodiment 3

[0036] Use a pipette to draw 0.30ml palladium nitrate aqueous solution into a beaker, heat and evaporate to dryness, put a certain amount of n-tetradecylamine, then add 15.0 n-octane, 2.5ml octanol and 0.20ml 0.1MKOH ethanol solution to make The molar ratio of n-tetradecylamine to palladium nitrate is 30:1, and the volume ratio of n-octane to absolute ethanol is 3:1. The system was ultrasonically shaken for about 20 minutes to 1 hour, and the resulting system was a clear solution. Place the beaker in the center of the microwave tray and stir on medium speed for about 5 minutes. Then heat continuously for 30 seconds with a modified microwave oven, the frequency is 2450 MHz, and the power is 500 W. After the solution changes color, stop heating, stop heating, and continue stirring for 10 minutes to obtain black palladium sol.

[0037] The resulting palladium sol was rotary evaporated to nearly dryness, and absolute ethanol was added therein, and the palladium nanoparticles prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com