Size defining method for preparing intermediate phase asphalt base foam carbon

A technology of mesophase pitch and carbon foam, which is applied in the field of size-limited production of mesophase pitch-based carbon foam, can solve the problems of increasing the cost of foam carbon equipment, increasing the cost of foam carbon operation, and complicated operation process, so as to reduce operating costs, The effect of reducing equipment cost and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 4.0 g of petroleum-based mesophase pitch micropowder (through a 180 mesh sieve) with a mesophase content of 98% (volume) as a raw material, and its softening point is 290° C. Place the weighed mesophase pitch raw material in a covered stainless steel foaming container with a cylindrical space, and then vibrate the mesophase pitch powder. The cylindrical space size of the stainless steel foaming container is φ30mm×25mm. The material volume accounts for 2 / 5 of the volume of the foamer. Then the foaming container was placed in a muffle furnace to raise the temperature to 460°C at a heating rate of 200°C / min. After staying at this temperature for 0.5h, it was cooled at a cooling rate of 1°C / min to obtain foamed charcoal. The foamed carbon was placed in a tubular oxidation furnace and raised to 350°C at a rate of 0.05°C / min, and then cooled at a rate of 8°C / min after constant temperature for 1 hour to obtain oxidized foamed carbon. Pass 1m during the oxidation proces...

Embodiment 2

[0021] Weigh 4.5g of the above-mentioned mesophase pitch micropowder, add it into the foaming container according to the steps in Example 1, and foam it under the same foaming conditions after vibration. In this case, the free space after filling the foam container is φ30mm×11.3mm. Other process conditions are the same as in Embodiment 1. The average pore size, porosity, and open porosity data of the obtained carbonized and graphitized carbon foams are shown in Table 2.

[0022]

Embodiment 3

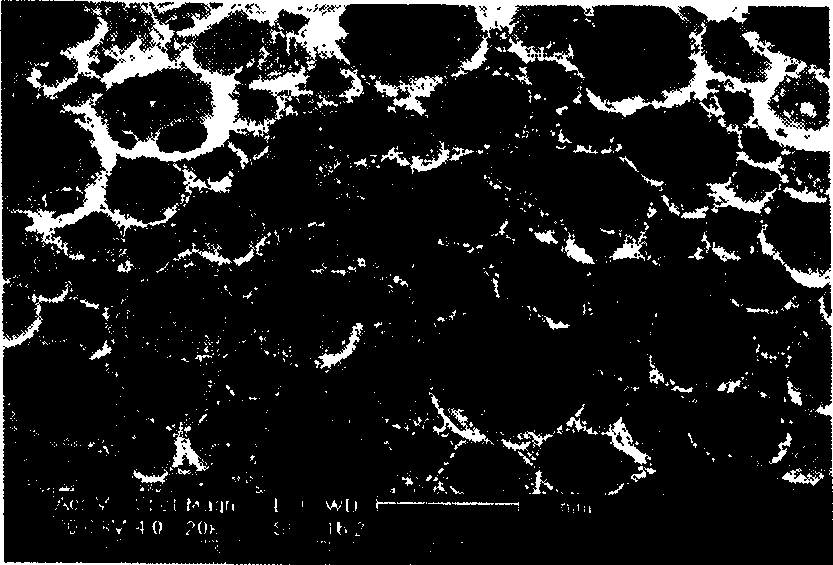

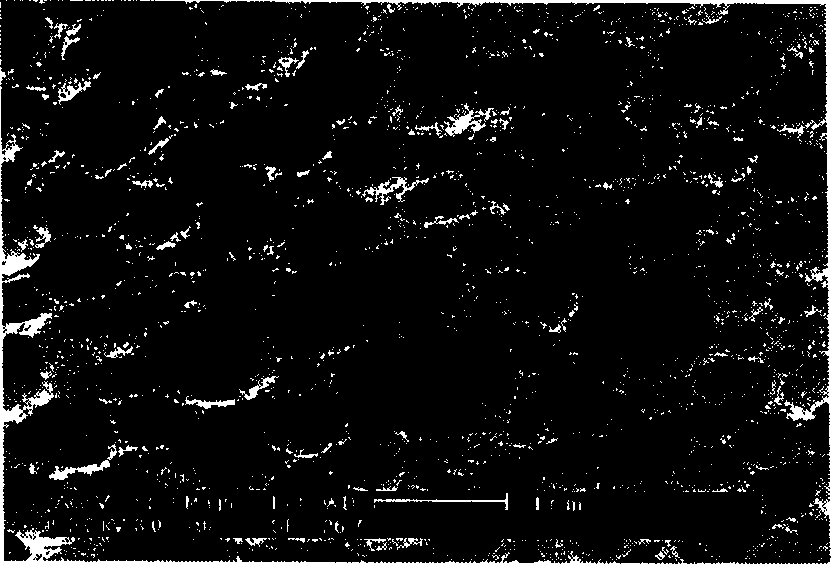

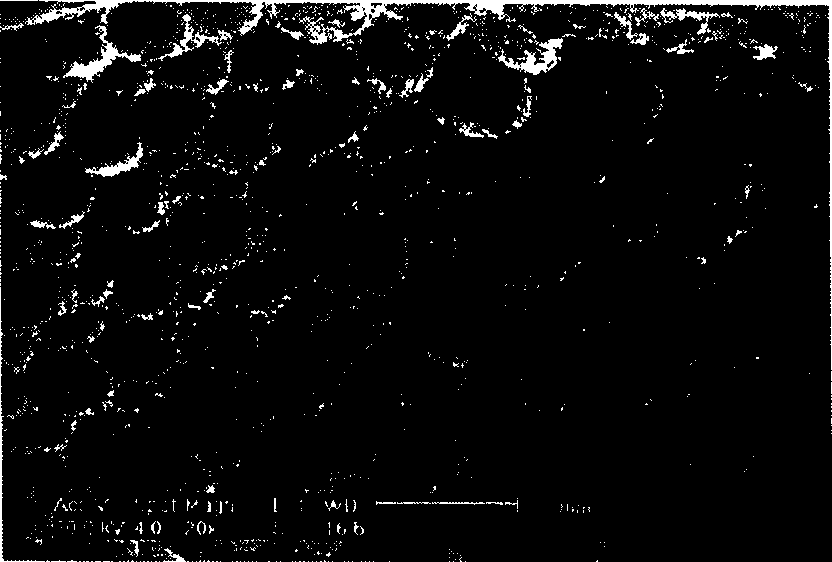

[0024] Weigh 5.0 g of the above-mentioned mesophase pitch micropowder, add it into the foaming container according to the steps in Example 1, and foam it under the same foaming conditions after vibration. Other process conditions are the same as in Embodiment 1. The scanning electron micrographs of the obtained carbonized and graphitized mesophase pitch-based carbon foams are as follows: image 3 and Figure 4 As shown, their average pore size, porosity, and open porosity data are shown in Table 3.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com