A nitrogen-doped porous carbon-supported molybdenum carbide catalyst and its preparation method and application

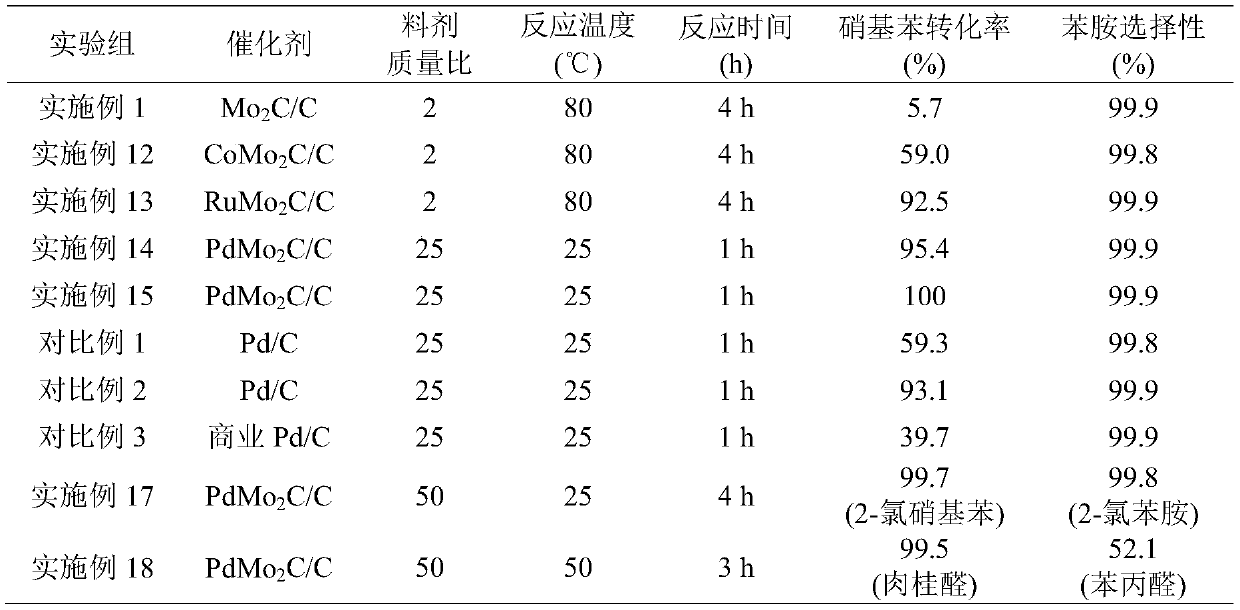

A catalyst, molybdenum carbide technology, used in the preparation of carbon-based compounds, catalysts for physical/chemical processes, preparation of amino compounds, etc., can solve the problems of limited number of active sites, easy sintering and agglomeration, low reaction activity, etc., to achieve excellent catalysis The effect of good activity, stability, catalytic activity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

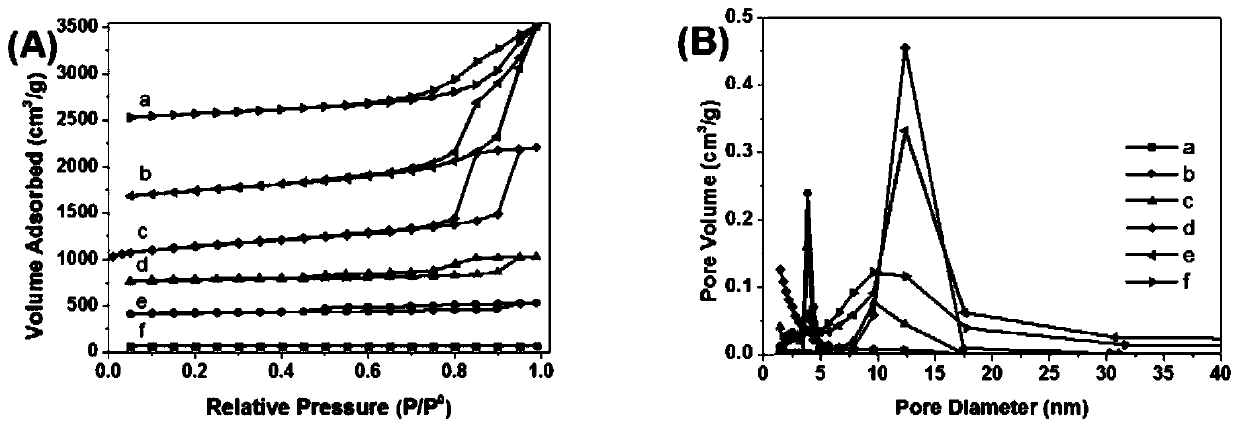

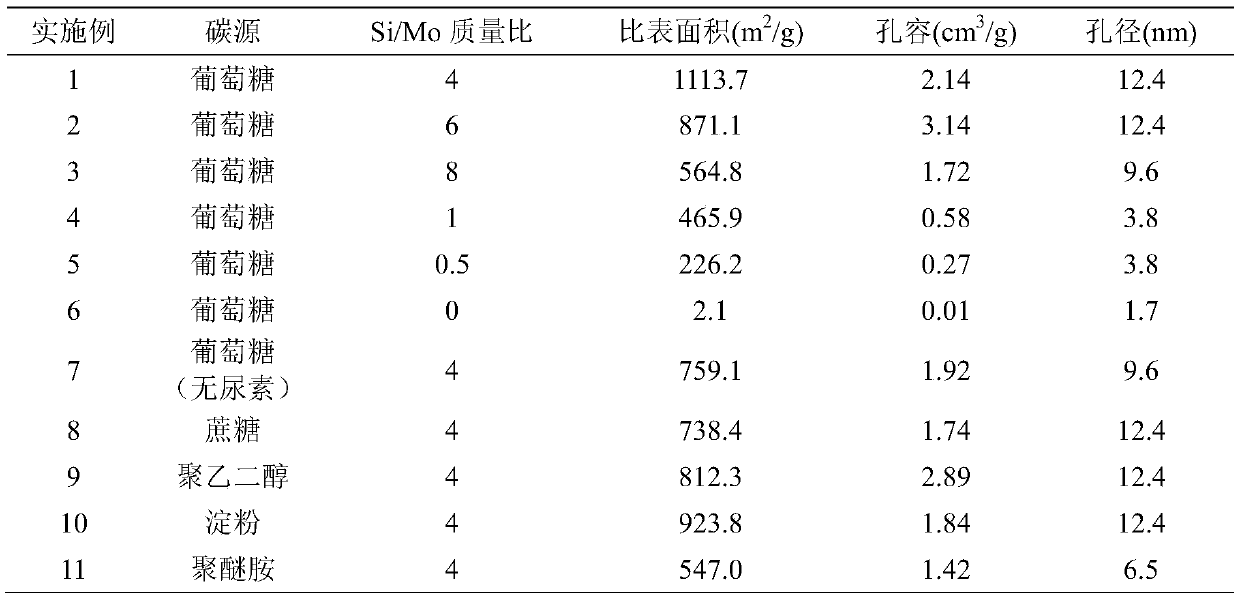

[0020] Example 1: Weigh 3.0 g of glucose and 5.0 g of urea, and continue to stir for 20 min under heating at 120° C. After forming a uniform solution, add 0.88 g of ammonium molybdate tetrahydrate and mix well. Weigh 10.3g of 40wt% silica sol (Si / Mo mass ratio is 4), add the above solution, and stir for 10min. Then, the obtained mixed solution was put into an oven at 180° C. for carbonization reaction, and the reaction time was 24 hours. The obtained black powder is placed in the constant temperature zone of the tubular resistance furnace, raised to 800°C at a heating rate of 2°C / min and kept at a constant temperature for 3 hours, cooled to room temperature after the reaction, treated with lye for 5 hours, filtered and washed with water, and dried. Nitrogen-doped porous carbon-supported molybdenum carbide catalysts are available. The pore structure properties of the prepared catalysts are as follows figure 1 and Table 1, from figure 1 It can be seen from Table 1 that the ni...

Embodiment 2

[0021] Example 2: The preparation process is the same as that of Example 1, the only difference is that the amount of silica sol added is adjusted to 15.5 g, and the mass ratio of Si / Mo is 6.

Embodiment 3

[0022] Example 3: The preparation process is the same as that of Example 1, the only difference is that the amount of silica sol added is adjusted to 20.6g, and the mass ratio of Si / Mo is 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com