Preparation method of vinyl chloride-vinyl acetate resin with uniformly distributed blocks

A technology of vinyl acetate copolymer resin with uniform distribution, applied in the production of bulk chemicals, etc., can solve the problems of uneven block distribution, dense surface film, low internal porosity, etc., to achieve non-toxic production process, increase porosity, etc. , recycling simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Count 0.9kg VC and 0.1kgVAc monomer into the reactor, add 1.0kg supercritical fluid CO according to the first group formula in Table 1 2 , 20.0g supercritical enhancer C 15 h 31 ArOH, 0.5g initiator cumene hydroperoxide / Na 2 S 2 o3 , add 1.5g of reaction auxiliary PVA, seal the reaction kettle, stir and heat up to 30°C, then raise the temperature to 50°C at a rate of 0.4°C / min, and the polymerization pressure is 10MPa. After 4 hours of reaction, add the terminator p-tert-butyl o Hydroquinone 1.5g, after stirring for 10min, open the valve to volatilize the solvent and additives in about 15s, and the gas enters the gas separation and recovery system. The obtained solid is washed with water and dried to obtain the pure product copolymerized resin.

Embodiment 2~ Embodiment 16

[0040] With reference to the method described in Example 1, according to the raw material formula ratio and process workpiece parameters recorded in Tables 1 to 3 (the data of the first group in the corresponding Tables 1 to 3 in Embodiment 1), replace them with 2 to 16 respectively. The data of the group correspond to Example 2 to Example 16.

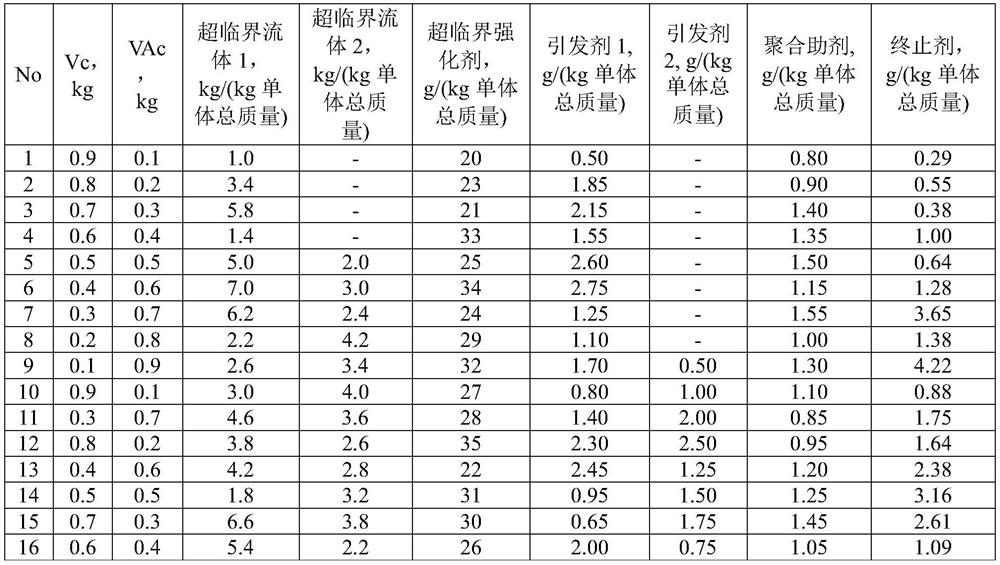

[0041] Table 1 Recipe table

[0042]

[0043] Note: bpy means cuprous chloride / bipyridine

[0044] Table 2 ratio table

[0045]

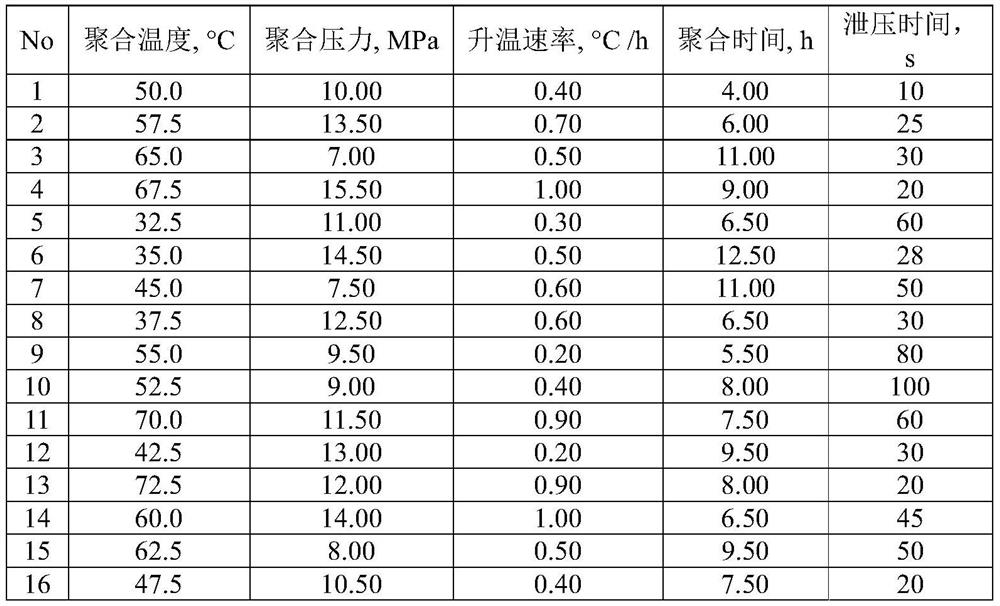

[0046] Table 3 process condition table

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com